Abstract

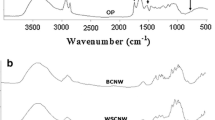

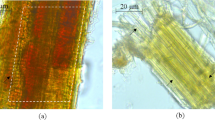

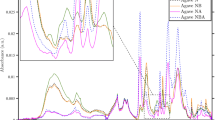

As the main byproduct of beer production, huge amounts of brewer´s spent grain (BSG) are generated annually worldwide. BSG is being currently underutilized since they are mostly devoted to animal feeding. Nevertheless, BSG offers a wide range of upcycling possibilities due to its lignocellulosic nature. In this work, we have addressed the extraction of cellulose and its further conversion into cellulose acetate, a biodegradable polymer with potential industrial application, especially as food contact material. The effectiveness of both processes, cellulose extraction and acetate synthesis were monitored by performing a comprehensive physicochemical characterization of the products. The influence of reaction time (1–5 h) on acetylation extent and acetate properties was also assessed. The results reflected that the process effectively removed hemicelluloses and lignin from BSG, and yielded a cellulose pulp with 63% crystallinity and 351 °C maximum degradation temperature. However, around 28% of the cellulose was solubilized, with acid pretreatment as the most aggressive step (above 19% disappearance). Acetylation extent was practically not affected by reaction time, and cellulose acetate with degree of substitution approximately 2.60 was obtained already after 1 h. Infrared spectra and X-ray diffractograms were similar for all acetate samples. Nevertheless, the thermogravimetric analysis evidenced that at least 3 h were needed to obtain a product with high thermal stability. This work addressed for the first time the acetylation of cellulose isolated from BSG, and may serve as basis for the manufacturing of a biobased plastic with application in sectors such as food packaging.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article.

References

BarthHaas R (2022) /2023 https://www.barthhaas.com/resources/barthhaas-report

Mussatto SI, Roberto IC (2006) Chemical characterization and liberation of pentose sugars from brewer´s spent grain. J Chem Technol Biotechnol 81(3):268–274. https://doi.org/10.1002/jctb.1374

Dos Santos DM, De Lacerda Bukzem A, Ascheri DPR, Signini R, De Aquino GLB (2015) Microwave-assisted carboxymethylation of cellulose extracted from brewer´s spent grain. Carbohydr Polym 131:125–133. https://doi.org/10.1016/j.carbpol.2015.05.051

Ravindran R, Jaiswal S, Abu-Ghannam N, Jaiswal AK (2018) A comparative analysis of pretreatment strategies on the properties and hydrolysis of brewers’ spent grain. Bioresour Technol 248:272–279. https://doi.org/10.1016/j.biortech.2017.06.039

Steiner J, Procopio S, Becker T (2015) Brewer´s spent grain: source of value-added polysaccharides for the food industry in reference to the health claims. Eur Food Res Technol 241(3):303–315. https://doi.org/10.1007/s00217-015-2461-7

Lynch KM, Steffen EJ, Arendt EK (2016) Brewers’ spent grain: a review with an emphasis on food and health. J Inst Brew 122:553–568. https://doi.org/10.1002/jib.363

Bachmann SAL, Calvete T, Féris LA (2022) Potential applications of brewery spent grain: critical an overview. J Environ Chem Eng 10(1):106951. https://doi.org/10.1016/j.jece.2021.106951

Edgar KJ, Buchanan CM, Debenham JS, Rundquist PA, Seiler BD, Shelton MC, Tindall D (2001) Advances in cellulose ester performance and application. Prog Polym Sci 26(9):1605–1688. https://doi.org/10.1016/S0079-6700(01)00027-2

Kramar A, Luxbacher T, González-Benito J (2023) Solution blow co-spinning of cellulose acetate with poly(ethylene oxide). Structure, morphology, and properties of nanofibers. Carbohydr Polym 320:121225. https://doi.org/10.1016/j.carbpol.2023.121225

Fischer S, Thümmler K, Volkert B, Hettrich K, Schmidt I, Fischer K (2008) Properties and applications of cellulose acetate. Macromol Symp 262(1):89–96. https://doi.org/10.1002/masy.200850210

Teixeira SC, Silva RRA, de Oliveira TV, Stringheta PC, Pinto MRMR, Soares NFF (2021) Glycerol and triethyl citrate plasticizer effects on molecular, thermal, mechanical, and barrier properties of cellulose acetate films. Food Biosci 42:101202. https://doi.org/10.1016/j.fbio.2021.101202

Cao Y, Wu J, Meng T, Zhang J, He J, Li H, Zhang Y (2007) Acetone-soluble cellulose acetates prepared by one-step homogeneous acetylation of cornhusk cellulose in an ionic liquid 1-allyl-3-methylimidazolium chloride (AmimCl). Carbohydr Polym 69(4):665–672. https://doi.org/10.1016/j.carbpol.2007.02.001

Biswas A, Shogren RL, Willett JL (2005) Solvent-free process to esterify polysaccharides. Biomacromolecules 6(4):1843–1845. https://doi.org/10.1021/bm0501757

Ding J, Li C, Liu J, Lu Y, Qin G, Gan L, Long M (2017) Time and energy-efficient homogeneous transesterification of cellulose under mild reaction conditions. Carbohydr Polym 157:1785–1793. https://doi.org/10.1016/j.carbpol.2016.11.063

Cheng HN, Dowd MK, Selling GW, Biswas A (2010) Synthesis of cellulose acetate from cotton byproducts. Carbohydr Polym 80(2):449–452. https://doi.org/10.1016/j.carbpol.2009.11.048

Sharma A, Giri SK, Kartha KPR, Sangwan RS (2017) Value-additive utilization of agro-biomass: preparation of cellulose triacetate directly from rice straw as well as other cellulosic materials. RSC Adv 7(21):12745–12752. https://doi.org/10.1039/c7ra00078b

Nu DTT, Hung NP, Van Hoang C, Van der Bruggen B (2019) Preparation of an asymmetric membrane from sugarcane bagasse using DMSO as green solvent. Appl Sci 9(16):3347. https://doi.org/10.3390/app9163347

Candido RG, Gonçalves AR (2016) Synthesis of cellulose acetate and carboxymethylcellulose from sugarcane straw. Carbohydr Polym 152:679–686. https://doi.org/10.1016/j.carbpol.2016.07.071

Candido RG, Godoy GG, Gonçalves A (2017) Characterization and application of cellulose acetate synthesized from sugarcane bagasse. Carbohydr Polym 167:280–289. https://doi.org/10.1016/j.carbpol.2017.03.057

Araújo D, Castro MCR, Figueiredo A, Vilarinho M, Machado A (2020) Green synthesis of cellulose acetate from corncob: physicochemical properties and assessment of environmental impacts. J Clean Prod 260:120865. https://doi.org/10.1016/j.jclepro.2020.120865

Morales-Juárez AA, Terrazas Armendáriz LD, Alcocer-González JM, Chávez-Guerrero L (2023) Potential of nanocellulose as a dietary fiber isolated from brewer´s spent grain. Polymers 15(17):3613. https://doi.org/10.3390/polym15173613

Oztuna Taner O, Ekici L, Akyuz L (2023) CMC-based edible coating composite films from Brewer´s spent grain waste: a novel approach for the fresh strawberry package. Polym Bull 80(8):9033–9058. https://doi.org/10.1007/s00289-022-04490-x

Mussatto SI, Rocha GJM, Roberto IC (2008) Hydrogen peroxide bleaching of cellulose pulps obtained from brewer´s spent grain. Cellulose 15(4):641–649. https://doi.org/10.1007/s10570-008-9198-4

Mandalari G, Faulds CB, Sancho AI, Saija A, Bisignano G, Locurto R, Waldron DW (2005) Fractionation and characterisation of arabinoxylans from brewers´ spent grain and wheat bran. J Cereal Sci 42(2):205–212. https://doi.org/10.1016/j.jcs.2005.03.001

de Crane d´Heysselaer S, Bockstal L, Jacquet N, Schmetz Q, Richel A (2022) Potential for the valorisation of brewer´s spent grains: a case study for the sequential extraction of saccharides and lignin. Waste Manag Res 40(7):1007–1014. https://doi.org/10.1177/0734242X211055547

Mussatto SI, Fernandes M, Roberto IC (2007) Lignin recovery from brewer´s spent grain black liquor. Carbohydr Polym 70(2):218–223. https://doi.org/10.1016/j.carbpol.2007.03.021

Sustainable Development Goals. Department of Economic and Social Affairs, United Nations. https://sdgs.un.org/goals

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. National renewable energy laboratory. Laboratory Analytical Procedure (LAP). Scientific Research Publishing, Wuhan

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-Ray diffractometer. Text Res J 29(10):786–794. https://doi.org/10.1177/004051755902901003

Johar N, Ahmad I, Dufresne A (2012) Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind Crops Prod 37(1):93–99. https://doi.org/10.1016/j.indcrop.2011.12.016

Zhou L, He H, Jiang C, Ma L, Yu P (2017) Cellulose nanocrystals from cotton stalk for reinforcement of poly(vinyl alcohol) composites. Cellul Chem Technol 51(1–2):109–119

Kassab Z, Abdellaoui Y, Hamid Salim M, Bouhfid R, El Kacem Qaiss A, El Achaby M (2020) Micro- and nano-celluloses derived from hemp stalks and their effect as polymer reinforcing materials. Carbohydr Polym 245:116506. https://doi.org/10.1016/j.carbpol.2020.116506

Amaral HR, Cipriano DF, Santos MS, Schettino MA, Ferreti JVT, Meirelles CS, Pereira VS, Cunha AG, Emmerich FG, Freitas JCC (2019) Production of high-purity cellulose, cellulose acetate and cellulose-silica composite from babassu coconut shells. Carbohydr Polym 210:127–134. https://doi.org/10.1016/j.carbpol.2019.01.061

Adebajo MO, Frost RL (2004) Acetylation of raw cotton for oil spill cleanup application: an FTIR and 13C MAS NMR spectroscopic investigation. Spectrochim Acta A Mol Biomol Spectrosc 60(10):2315–2321. https://doi.org/10.1016/j.saa.2003.12.005

Nemr AE, Ragab S, Sikaily AE (2017) Rapid synthesis of cellulose triacetate from cotton cellulose and its effect on specific surface area and particle size distribution. Iran Polym J (English Edition) 26(4):261–272. https://doi.org/10.1007/s13726-017-0516-2

Fei P, Liao L, Cheng B, Song J (2017) Quantitative analysis of cellulose acetate with a high degree of substitution by FTIR and its application. Anal Methods 9(43):6194–6201. https://doi.org/10.1039/C7AY02165H

Li W, Cai G, Zhang P (2019) A simple and rapid Fourier transform infrared method for the determination of the degree of acetyl substitution of cellulose nanocrystals. J Mater Sci 54(10):8047–8056. https://doi.org/10.1007/s10853-019-03471-2

Kanauchi O, Mitsuyama K, Araki Y (2001) Development of a functional germinated barley foodstuff from brewer’s spent grain for the treatment of ulcerative Colitis. J Am Soc Brew Chem 59(2):59–62

Carvalheiro F, Esteves MP, Parajó JC, Pereira H, Gírio FM (2004) Production of oligosaccharides by autohydrolysis of brewery’s spent grain. Bioresour Technol 91(1):93–100. https://doi.org/10.1016/S0960-8524(03)00148-2

Silva JP, Sousa S, Rodrigues J, Antunes H, Porter JJ, Gonçalves I, Ferreira-Dias S (2004) Adsorption of acid orange 7 dye in aqueous solutions by spent brewery grains. Sep Purif Technol 40(3):309–315. https://doi.org/10.1016/j.seppur.2004.03.010

Xiros C, Topakas E, Katapodis P, Christakopoulos P (2008) Hydrolysis and fermentation of brewer’s spent grain by Neurospora Crassa. Bioresour Technol 99(13):5427–5435. https://doi.org/10.1016/j.biortech.2007.11.010

Jay AJ, Parker ML, Faulks R, Husband F, Wilde P, Smith AC, Faulds CB, Waldron KW (2008) A systematic micro-dissection of brewers’ spent grain. J Cereal Sci 47(2):357–364. https://doi.org/10.1016/j.jcs.2007.05.006

Robertson JA, I’Anson KJA, Treimo J, Faulds CB, Brocklehurst TF, Eijsink VGH, Waldron KW (2010) Profiling brewers’ spent grain for composition and microbial ecology at the site of production. LWT -Food Sci Technol 43(6):890–896. https://doi.org/10.1016/j.lwt.2010.01.019

Waters DM, Jacob F, Titze J, Arendt EK, Zannini E (2012) Fibre, protein and mineral fortification of wheat bread through milled and fermented brewer’s spent grain enrichment. Eur Food Res Technol 235(5):767–778. https://doi.org/10.1007/s00217-012-1805-9

Meneses NGT, Martins S, Teixeira JA, Mussatto SI (2013) Influence of extraction solvents on the recovery of antioxidant phenolic compounds from brewer’s spent grains. Sep Purif Technol 108:152–158. https://doi.org/10.1016/j.seppur.2013.02.015

Parchami M, Agnihotri S, Taherzadeh MJ (2022) Aqueous ethanol organosolv process for the valorization of Brewer´s spent grain (BSG). Bioresour Technol 362:127764. https://doi.org/10.1016/j.biortech.2022.127764

Klímek P, Wimmer R, Mishra PK, Kúdela J (2017) Utilizing brewer´s-spent-grain in wood-based particleboard manufacturing. J Clean Prod 141:812–817. https://doi.org/10.1016/j.jclepro.2016.09.152

Andrade Alves JA, Lisboa dos Santos MD, Morais CC, Ramirez Ascheri JL, Signini R, dos Santos DM, Cavalcante Bastos SM, Ramirez Ascheri DP (2019) Sorghum straw: Pulping and bleaching process optimization and synthesis of cellulose acetate. Int J Biol Macromol 135:877–886. https://doi.org/10.1016/j.ijbiomac.2019.05.014

Sun XF, Jing Z, Fowler P, Wu Y, Rajaratnam M (2011) Structural characterization and isolation of lignin and hemicelluloses from barley straw. Ind Crops Prod 33(3):588–598. https://doi.org/10.1016/j.indcrop.2010.12.005

Elyamine AM, Moussa MG, Afzal J, Rana MS, Imran M, Zhao X, Hu CX (2019) Modified rice straw enhanced cadmium (II) immobilization in soil and promoted the degradation of phenanthrene in co-contaminated soil. Int J Mol Sci 20:2189. https://doi.org/10.3390/ijms20092189

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21(2):885–896. https://doi.org/10.1007/s10570-013-0030-4

Barud HS, de Araújo Júnior AM, Santos DB, de Assunçāo RMN, Meireles CS, Cerqueira DA, Rodrigues Filho G, Ribeiro CA, Messaddeq Y, Ribeiro SJL (2008) Thermal behavior of cellulose acetate produced from homogeneous acetylation of bacterial cellulose. Thermochim Acta 471(1–2):61–69. https://doi.org/10.1016/j.tca.2008.02.009

French AD, Santiago Cintrón M (2013) Cellulose polymorphy, crystallite size, and the segal crystallinity index. Cellulose 20(1):583–588. https://doi.org/10.1007/s10570-012-9833-y

Matebie BY, Tizazu BZ, Kadhem AA, Venkatesa Prabhu S (2021) Synthesis of cellulose nanocrystals (CNCs) from brewer´s spent grain using acid hydrolysis: characterization and optimization. J Nanomater 2021:7133154. https://doi.org/10.1155/2021/7133154

Melikoğlu AY, Bilek SE, Cesur S (2019) Optimum alkaline treatment parameters for the extraction of cellulose and production of cellulose nanocrystals from apple pomace. Carbohydr Polym 215:330–337. https://doi.org/10.1016/j.carbpol.2019.03.103

Akinjokun AI, Petrik LF, Ogunfowokan AO, Ajao J, Ojumu TV (2021) Isolation and characterization of nanocrystalline cellulose from cocoa pod husk (CPH) biomass wastes. Heliyon 7(4):e06680. https://doi.org/10.1016/j.heliyon.2021.e06680

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86(12–13):1781–1788. https://doi.org/10.1016/j.fuel.2006.12.013

Morán JI, Alvarez VA, Cyras VP, Vázquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15(1):149–159. https://doi.org/10.1007/s10570-007-9145-9

Das AM, Ali AA, Hazarika MP (2014) Synthesis and characterization of cellulose acetate from rice husk: eco-friendly condition. Carbohydr Polym 112:342–349. https://doi.org/10.1016/j.carbpol.2014.06.006

Umaningrum D, Astuti MD, Nurmasari R, Hasanuddin H, Mulyasuryani A, Mardiana D (2021) Variation of iodine mass and acetylation time on cellulose acetate synthesis from rice straw. Indo J Chem Res 8(3):228–233. https://doi.org/10.30598//ijcr.2021.7-dew

Fan G, Wang M, Liao C, Fang T, Li J, Zhou R (2013) Isolation of cellulose from rice straw and its conversion into cellulose acetate catalyzed by phosphotungstic acid. Carbohydr Polym 94(1):71–76. https://doi.org/10.1016/j.carbpol.2013.01.073

Rodrigues Filho G, Monteiro DS, Meireles CS, de Assunçāo RM, Cerqueira DA, Barud HS, Ribeiro SJL, Messadeq Y (2008) Synthesis and characterization of cellulose acetate produced from recycled newspaper. Carbohydr Polym 73(1):74–82. https://doi.org/10.1016/j.carbpol.2007.11.010

Acknowledgements

The authors gratefully acknowledge the Provincial Council of Jaén (Spain) for funding this research (Grant number 2022/4090). L. Camacho-Núñez also acknowledges the cooperation between the University of Jaén and Andaltec I + D + i for the economic support received during the experimental phase of the study. We also thank the technical and human support provided by Centro de Instrumentación Científico-Técnica (CICT; University of Jaén) and Andaltec I + D + i laboratory staff, as well as M. José de la Mata (Autonomous University of Madrid) for performing the simultaneous TGA-DSC measurements.

Funding

This research was funded by the Provincial Council of Jaén (Spain) under Grant number 2022/4090.

Author information

Authors and Affiliations

Contributions

LCN: Methodology, Investigation, Writing‒Original Draft. SJC: Conceptualization, Methodology, Investigation, Writing‒Review and Editing. MDLR: Conceptualization, Resources, Writing‒Review and Editing, Supervision. FJNM: Conceptualization, Resources, Writing‒Review and Editing, Funding acquisition. JARL: Conceptualization, Resources, Writing‒Review and Editing, Supervision, Project administration, Funding acquisition.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Camacho-Núñez, L., Jurado-Contreras, S., La Rubia, M.D. et al. Cellulose-Based Upcycling of Brewer´s Spent Grains: Extraction and Acetylation. J Polym Environ (2023). https://doi.org/10.1007/s10924-023-03137-w

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-023-03137-w