Abstract

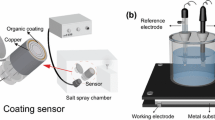

Evaluating the status and lifetime of organic coatings has great significance in structural safety. However, it is quite difficult to evaluate the lifetime of coatings priorly based on conventional visible indicators because they cannot measure the internal changes of coatings. In this paper, a new and effective composite indicator, i.e., circuit-resistance-impedance (CRI), is used to characterize the multi-source uncertainty of the performance degradation of coatings, and a three-stage electrochemical statistical model is proposed to evaluate the service life of organic coatings. Particularly, the Box-Cox transformation is first utilized to improve the normality of the distribution of corrosion rate. Then, a constrained maximum likelihood estimation algorithm considering failure mechanism equivalence is presented to estimate the unknown model parameters. Next, a time-varying reliability model is constructed based on proposed CRI failure criterion and the reliable lifetime of coatings is further evaluated. Finally, a rapid discrimination method of coating status is proposed through measuring the asynchrony of degradation using the coefficient of variation. A corrosion test for epoxy coatings is designed and conducted to demonstrate the effectiveness of the proposed models. Results indicate that they can significantly improve the rationality and validity of coatings lifetime evaluation.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Xu M, Lam CNC, Wong D, Asselin E (2020) Evaluation of the cathodic disbondment resistance of pipeline coatings—a review. Prog Org Coat 146:105728

Wang C, Elsayed EA (2020) Stochastic modeling of corrosion growth. Reliab Eng Syst Saf 204:107120

Cai Y, Xu Y, Zhao Y, Ma X (2021) Extrapolating short-term corrosion test results to field exposures in different environments. Corros Sci 186:109455

Xia DH, Deng CM, Macdonald D, Jamali S, Mills D, Luo JL, Strebl MG, Amiri M, Jin W, Song S, Hu W (2022) Electrochemical measurements used for assessment of corrosion and protection of metallic materials in the field: a critical review. J Mater Sci Technol 112:151–183

Nicolai RP, Dekker R, Van Noortwijk JM (2007) A comparison of models for measurable deterioration: an application to coatings on steel structures. Reliab Eng Syst Saf 92:1635–1650

Meng F, Liu L, Liu E, Zheng H, Liu R, Cui Y, Wang F (2021) Synergistic effects of fluid flow and hydrostatic pressure on the degradation of epoxy coating in the simulated deep-sea environment. Prog Org Coat 159:106449

Zhang M, Xu H, Zeze ALP, Liu X, Tao M (2022) Coating performance, durability and anti-corrosion mechanism of organic modified geopolymer composite for marine concrete protection. Cement Concr Compos 129:104495

Thomas D, Reshmy R, Philip E, Sindhu R, Ulaeto SB, Pugazhendhi A, Awasthi MK (2022) Developments in smart organic coatings for anticorrosion applications: a review. Biomass Convers Bioref 12:4683–4699

Hoang N, Khoa TA, Nhung LT, Phuong PM, Binh TD, Hang TTX, Chi NV, Nguyen TD (2022) Flake ZnAl alloy as an effective pigment in silicate coatings for the corrosion protection of steel. Coatings 12:1046

Qi C, Dam-Johansen K, Weinell CE, Bi H, Wu H (2022) Enhanced anticorrosion performance of zinc rich epoxy coatings modified with stainless steel flakes. Prog Org Coat 163:106616

Cao X, Huang F, Huang C, Liu J, Cheng YF (2019) Preparation of graphene nanoplate added zinc-rich epoxy coatings for enhanced sacrificial anode-based corrosion protection. Corros Sci 159:108120

An T, He Y, Feng Y (2020) Experimental study on compression behavior of fiber-reinforced resin-based composite stiffened panels in hygrothermal environment. Strength Mater 52:655–661

Xu Y, Song GL, Zheng D, Feng Z (2021) The corrosion damage of an organic coating accelerated by different AC-DC-AC tests. Eng Fail Anal 126:105461

Shreepathi S, Guin AK, Naik SM, Vattipalli MR (2010) Service life prediction of organic coatings: electrochemical impedance spectroscopy vs actual service life. J Coat Technol Res 8:191–200

Brunner S, Richner P, Müller U, Guseva O (2005) Accelerated weathering device for service life prediction for organic coatings. Polym Testing 24:25–31

Zhang S, Zhai Q, Li Y (2023) Degradation modeling and RUL prediction with Wiener process considering measurable and unobservable external impacts. Reliab Eng Syst Saf 231:109021

Kim I, Itoh Y (2007) Accelerated exposure tests as evaluation tool for estimating life of organic coatings on steel bridges. Corros Eng Sci Technol 42:242–252

Zhang Z, Wu J, Zhao X, Zhang Y, Wu Y, Su T, Deng H (2020) Life evaluation of organic coatings on hydraulic metal structures. Prog Org Coat 148:105848

Gao J, Hu W, Wang R, Li X (2021) Study on a multifactor coupling accelerated test method for anticorrosive coatings in marine atmospheric environments. Polym Testing 100:107259

Hinderliter BR, Croll SG, Tallman DE, Su Q, Bierwagen GP (2006) Interpretation of EIS data from accelerated exposure of coated metals based on modeling of coating physical properties. Electrochim Acta 51:4505–4515

Zuo Y, Pang R, Li W, Xiong JP, Tang YM (2008) The evaluation of coating performance by the variations of phase angles in middle and high frequency domains of EIS. Corros Sci 50:3322–3328

Guseva O, Brunner S, Richner P (2003) Service life prediction for aircraft coatings. Polym Degrad Stab 82:1–13

Gao J, Li C, Feng HX, Li XG (2020) In situ and dynamic observation of coating failure behavior. Prog Org Coat 138:105387

Zhang T, Zhang T, He Y, Wang Y, Bi Y (2022) Corrosion and aging of organic aviation coatings: a review. Chin J Aeronaut 36:1–35

Chandrasatheesh C, Jayapriya J, Prabunathan P (2021) Fabrication of Ag-TiO2/cardanol epoxy-based composite coatings against microbiologically influenced corrosion of mild steel. J Polym Environ 30:1528–1546

He D, Jiao F, Wu J, Ou D (2022) Thermal insulation and structural reliability of modified epoxy resin-based ablation thermal protection coatings in aerothermal-vibration coupling environment. Polym Eng Sci 63:521–530

Abbas RA, Ajeel SA, Ali Bash MA, Kadhim MJ (2021) Effect of plasma spray distance on the features and hardness reliability of YSZ thermal barrier coating. Mater Today Proc 42:2553–2560

González-González DS, Praga-Alejo RJ, Cantú-Sifuentes M (2016) A non-linear fuzzy degradation model for estimating reliability of a polymeric coating. Appl Math Model 40:1387–1401

Ciucci F (2019) Modeling electrochemical impedance spectroscopy. Curr Opin Electrochem 13:132–139

Li X, Ahmadi M, Collins L, Kalinin SV (2019) Deconvolving distribution of relaxation times, resistances and inductance from electrochemical impedance spectroscopy via statistical model selection: exploiting structural-sparsity regularization and data-driven parameter tuning. Electrochim Acta 313:570–583

Apetrei IM, Rodríguez-Méndez ML, Apetrei C, Nevares I, del Alamo M, de Saja JA (2012) Monitoring of evolution during red wine aging in oak barrels and alternative method by means of an electronic panel test. Food Res Int 45:244–249

Luo S, Sun H, Ping Q, Jin R, He Z (2016) A review of modeling bioelectrochemical systems: engineering and statistical aspects. Energies 9:111

Rozendal RA, Hamelers HVM, Buisman CJN (2006) Effects of membrane cation transport on pH and microbial fuel cell performance. Environ Sci Technol 40:5206–5211

Goroncharovskaya IV, Evseev AK, Shabanov AK, Denisenko O, Kuzovlev AN, Klychnikova EV, Tazina EV, Petrikov SS (2020) Electrochemical methods for assessment of polytrauma outcomes. Electroanalysis 33:550–557

Ghanei A, Eskandari-Naddaf H, Ozbakkaloglu T, Davoodi A (2020) Electrochemical and statistical analyses of the combined effect of air-entraining admixture and micro-silica on corrosion of reinforced concrete. Constr Build Mater 262:120768

Yuan H, Dai H, Ming P, Wang X, Wei X (2021) Quantitative analysis of internal polarization dynamics for polymer electrolyte membrane fuel cell by distribution of relaxation times of impedance. Appl Energy 303:117640

Gao Y, Zhang X, Zhu C, Guo B (2021) Global parameter sensitivity analysis of electrochemical model for lithium-ion batteries considering aging. IEEE/ASME Trans Mechatron 26:1283–1294

Cheng YF, Wilmott M, Luo JL (1999) The role of chloride ions in pitting of carbon steel studied by the statistical analysis of electrochemical noise. Appl Surf Sci 152:161–168

Sun X, Mraied H, Cai W, Zhang Q, Liang G, Li M (2018) Bayesian latent degradation performance modeling and quantification of corroding aluminum alloys. Reliab Eng Syst Saf 178:84–96

Karolczuk A, Kurek M (2022) Fatigue life uncertainty prediction using the Monte Carlo and Latin hypercube sampling techniques under uniaxial and multiaxial cyclic loading. Int J Fatigue 160:106867

Davies G, Weber R, Wilson K, Cummins P (2022) From offshore to onshore probabilistic tsunami hazard assessment via efficient Monte Carlo sampling. Geophys J Int 230:1630–1651

Zhang W, Chen XZ, Yin PF, Xu ZK, Han B, Wang J (2012) EIS study on the deterioration process of organic coatings under immersion and different cyclic wet-dry ratios. Appl Mech Mater 161:58–66

Hu JM, Zhang JT, Zhang JQ, Cao CN (2005) Corrosion electrochemical characteristics of red iron oxide pigmented epoxy coatings on aluminum alloys. Corros Sci 47:2607–2618

Janssen H (2013) Monte-Carlo based uncertainty analysis: sampling efficiency and sampling convergence. Reliab Eng Syst Saf 109:123–132

Chian CY, Zhao YQ, Lin TY, Nelson B, Huang HH (2018) Comparative study of time-domain fatigue assessments for an offshore wind turbine jacket substructure by using conventional grid-based and monte carlo sampling methods. Energies 11:3112

Li B, Ma Y, Njoku D, Meng M, Tang A, Li Y (2023) Design of anti-mildew smart microcapsules with chitosan as encapsulant for advanced electronic packaging epoxy coating. Prog Org Coat 180:107568

Atkinson AC, Riani M, Corbellini A (2021) The Box-Cox transformation: review and extensions. Stat Sci 36(239–255):217

Wang H, Zhao Y, Ma X, Wang H (2017) Optimal design of constant-stress accelerated degradation tests using the M-optimality criterion. Reliab Eng Syst Saf 164:45–54

Xu Y, Ran J, Dai W, Zhang W (2017) Investigation of service life prediction models for metallic organic coatings using full-range frequency EIS data. Metals 7:274

Hu J, Zhang J, Xie D, Cao C (2003) Impedance models of epoxy coated LY12 aluminum alloys in NaCl solution. Acta Phys Chim Sin 19:144–149

Li N, Yan X, Liu X, Han L, Zhang W (2022) Mechanical properties evolution of the 7B04-T74 aluminum alloy in the marine atmosphere. Metals 12:2173

Li N, Zhang W, Xu H, Cai Y, Yan X (2022) Corrosion behavior and mechanical properties of 30CrMnSiA high-strength steel under an indoor accelerated harsh marine atmospheric environment. Materials (Basel) 15:629

Funding

This work was supported in part by National Natural Science Foundation of China under Grant 52075020 and Grant 72201019, and in part by Basic Technical Research Project of China under Grant JSZL2018601B004.

Author information

Authors and Affiliations

Contributions

HJ: Conceptualization, Methodology, Software, Writing—Original draft preparation. XM: Resources, Project administration, Supervision. YC: Data curation, Writing—Review & Editing. HW: Validation, Funding acquisition. QC: Software, Validation.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ji, H., Ma, X., Cai, Y. et al. Degradation Modeling and Lifetime Evaluation for Organic Anti-Corrosion Coatings Using a Three-Stage Electrochemical Statistical Model. J Polym Environ 32, 1046–1064 (2024). https://doi.org/10.1007/s10924-023-03015-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-023-03015-5