Abstract

Grape pomace, as by-product of wine making, is a source of polyphenols, fibers, fatty acids, metals, and organic acids, which could be used as raw component for the production of sustainable materials. Novel biodegradable films based on pomaces, from Negroamaro (red) and Fiano (white), Italian grape cultivars, were fabricated. Physical, chemical and antioxidant properties of material produced were characterized. In particular, migration tests of phenols from pomace films to aqueous food simulant medium were investigated. Data obtained allowed to evaluate the antioxidant activity in terms of total phenol assay and Trolox Equivalent Antioxidant Capacity assay and phenols profile. The characterization of phenolic composition confirmed the peculiarity of some compounds such as anthocyanins (191.17 ± 10.3 μg/g film) in red skin pomace film (NPF) and a great amount of flavanols (76.36 ± 1.72 μg/g film) in white skin pomace film (FPF). Antioxidant activity of polyphenols resulted in active films and was confirmed in migration test with aqueous food simulants. Physical properties of produced films were then studied in terms of morphological, thermal, mechanical and barrier properties. Finally, in the framework of sustainability and circular economy, the presented data paves the way to the design and production of active materials for packaging application starting from a widely available by-product derived from wine-making chain.

Similar content being viewed by others

Introduction

Nowadays, food packaging is still produced from fossil fuels, which is representing a great environmental concern. The development of novel, eco-friendly and sustainable active packaging is emerging as an urgent issue [1]. Many efforts have been making to reduce packaging wastes and guarantee, in the same time, food stability and quality. So, focus has been put on the fabrication of bio-based materials from renewable sources due to their biodegradability [2, 3]. In fact, biodegradable films and coatings are now emerging as novel alternatives to conventional plastics to fabricate eco-friendly food packaging [4]. Many materials have already been used for the formulation of bio-based films such as polysaccharides, protein, lipids [5]. Moreover, there is an increased attention in the utilization of food waste or food chain processing by-products [14,15,16]. Most of these, though, are underutilized because of their low market value [17]. It is known that the processing of fruit and vegetables produces a noticeable amount of residues such as peels, seeds, pulp and stone which usually are rich in bioactive compounds [18, 19]. The fabrication of edible films derived from food processing by-products has been widely studying since this kind of material can combine the film-forming properties of biopolymers (i.e. pectin and cellulose) with the properties (i.e. color and flavor) of pigments and active compounds such as antioxidant and antimicrobial agents [20, 21]. These biomolecules could contribute to increase the shelf life of packaged food products [22]. Different kind of materials have already been applied to produce biodegradable packaging such as potato peel [23], rice husk [24], apple waste [25], onion [26], tropical fruits [1, 27,28,29,30], nut [31], cereals [32] and wine pomace [21]. Previous studies concern, for example, the fabrication of bio-based high-density polyethylene films with phenolic compounds present in citrus fruits and grapes as natural antioxidants [6], antioxidant films based on ethylene vinyl alcohol copolymer and caffeic acid [7], chitosan and grape seed extract-based edible films [8], polyethylene terephthalate trays coated with citrus extract [9], quercetin loaded carboxymethyl cellulose, gelatin, and poly(lactic acid) [10], mango leaf extract incorporated chitosan films [11], polyvinyl alcohol and apple pomace bio-composite films with antioxidant properties [12] and carboxymethyl cellulose-based antioxidant and antimicrobial active packaging film incorporated with curcumin and zinc oxide [13]. Among all the natural materials used for packaging applications, wine pomace, as natural by-product, is taking a great interest. It is derived from wine processing (about 25% of the weight of wine making process consist in pomace) and mainly composed of skin, seeds, stems. These byproducts represent a source of dietary fibers and a significant amount of polyphenols [33,34,35,36]. Nowadays, wine pomace is used as health food supplement, biogas conversion or simply discarded as a waste. Currently, the interest in using it for functional foods, cosmetic, pharmaceuticals, food supplements is increasing [35, 37, 38]. The presence of pectin, cellulose and sugars adds benefits to the film formation application while the skins and seeds of grapes are known to be rich sources of phenolic compounds, both flavonoids and non-flavonoids [35, 39]. These characteristics make the grape pomace suitable for the production of biodegradable films. For example, Deng et al. produced wine grape pomace (cv. Merlot) extract-based films [21], Saurabh et al. fabricated guar gum based active packaging films using grape pomace (Shiraz variety) [40], Ribeiro et al. fabricated arrowroot starch films incorporated with grape pomace extract (BRS Violeta) [41], Ferreira et al. produced grape pomace extract (Vitis vinifera, var. Touriga Nacional) incorporated in chitosan films [42] while Xu et al. produced starch nanocomposite films incorporating grape pomace extract (Vitis vinifera, var. Viognier) and cellulose nanocrystal [43]. This study investigates the feasibility of fabricating novel biodegradable film by utilizing grape pomace from two Italian grape cultivars named Fiano and Negroamaro, derived from the wine making processes. Fiano (Vitis vinifera L) is the most representative sweet white wine variety in the Campania region of Italy [44] while Negroamaro is a non-aromatic red wine grape cultivar originally from Apulia region, southeast Italy [45]. The two kinds of grape pomaces have been used to fabricate novel and green thin films for food packaging applications. The produced films have been widely characterized from physical, chemical and antioxidant properties.

Material and Methods

Materials

Two batches of wine pomace (grape harvest year 2018), Vitis vinifera varieties Negroamaro (N) (achieved after fermentation for red wine making), and Fiano (F) (without fermentation, as it is used in white wine making) were obtained from a commercial winemaking facility located in Salento (Apulia region, Southern Italy). The pomace was dried in an oven at 50 °C until constant weight and subsequently, the skins were manually recovered from a part of pomace. Separated skins grape pomace were milled into flour using a Brabender Quadrumat Senior mill (C.W. Brabender OHG, Germany) with a particle size ≤ 1 mm. Sodium Alginate (CAS: 9005-38-3) and Glycerol (CAS: 56-81-5) were purchased from Sigma Aldrich. Pectin from apple (CAS Number: 9000-69-5) was purchased from Sigma Aldrich in powder form. Other reagents were acquired from various suppliers: authentic standards of oenin (Malvidin-3-O-glucoside), rutin (quercetin 3-O-rutinoside) from Extrasynthèse (Genay, France); gallic acid, caffeic acid, caftaric acid, coutaric acid, catechin, epicatechin, quercetin3-glucoside, Folin–Ciocalteu phenol reagent, Trolox [(S)-(-)-6-hydroxy-2,5,7,8 tetramethylchroman-2-carboxylic acid], acetonitrile, formic acid, ethanol, (all HPLC grade) from Sigma-Aldrich (St. Louis, MO, USA). Milli-Q water (Merck Millipore, Darmstadt, Germany) was used for the preparation of reagents and antioxidant assays.

Biocomposites Preparation

Fiano and Negroamaro skin grape pomace powder were firstly dried at T = 70 °C in a vacuum oven for 12 h. The matter was then sieved using a molecular sieve with a mesh of 250 μm. The obtained powder was then used as raw material for the preparation of bio-composites.

Bio-composites were prepared solubilizing 1 g of grape pomace in 30 mL of distilled water. 0.1 g of sodium alginate and 0.1 g of pectin were added as film forming materials. Glycerol was added as a plasticizer (0.2 g/g of solid mixture). The solution was stirred at 300 rpm for 3 h. The effect of temperature was investigated by setting three different values (20 °C, 50 °C and 100 °C). After completely solubilizing the pomace powder, the mixture was ball milled for 1 h at 350 rpm, using five zirconium oxide spheres as grinding medium. The mixture was then poured in Petri dishes for the casting process at r. t. The fabricated films are labeled FPF (Fiano pomace film) and NPF (Negroamaro pomace film).

Grape Pomace Film Extracts

Phenol compounds were extracted from Fiano and Negroamaro grape skin pomace films (FPF and NPF respectively). Films were frozen in liquid nitrogen and grinded until a fine powder was obtained. The obtained powders were extracted in methanol:ethanol:formic acid (75:20:5, v:v) at a rate of 1 g in 10 ml. Extraction was performed at room temperature for 16 h in the dark under continuous stirring. Extraction mixtures were centrifuged (4000×g) for 5 min and the supernatants were stored at − 20 °C till analysis.

Migration Tests of Phenols from Films to Food Simulants

Migration tests were performed following the methodology reported by Medina-Jaramillo [46], and Article 2 of the EEC (European Economic Community Directive 85/572/EEC) [47], which indicate that water can be used as aqueous simulant of foods. Samples (film pieces of ∼ 200 mm2) were deposited in 5 mL of water and placed in an orbital shaker at 25 °C at 100 rpm overnight in the dark. After that, migration of polyphenols was evaluated as reported by Magalhães et al. (2010) and expressed as mg of gallic acid equivalents (GAE)/g of film. Moreover, released molecules were characterized by High Performance Liquid Chromatography (HPLC) and antioxidant activity of released molecules was assayed by Trolox Equivalent Antioxidant capacity (TEAC) and expressed as μmol of Trolox Equivalents (TE)/g of films.

Total Phenol Assay

Total phenols both in grape skin pomace film extracts and migrated from films to aqueous simulant, were assayed as reported by Magalhães et al. (2010) in 96-well plates (Corning) using a microplate reader (Tecan, Infinite M200). Folin-Ciocalteu reagent (1:5, v/v) (50 μL) was placed in each well, and then 100 μL of sodium hydroxide solution (0.35 M) was added. The absorbance at 760 nm of the blue complex formed was monitored after 5 min. Gallic acid was used to obtain a calibration curve in the range from 2.5 to 40.0 mg/L (R ≥ 0.9997). The total phenol content of the samples was expressed as gallic acid equivalents.

Trolox Equivalent Antioxidant Capacity (TEAC) Assay

The TEAC assay of grape skin pomace film extracts and of phenols migrated from film to aqueous simulant of foods, was performed trough the method reported by Gerardi et al. [35]. Briefly, the ABTS radical cation was diluted in PBS (pH 7.4) to an absorbance of 0.40 at 734 nm. After the addition of 200 μL of diluted ABTS to 10 μL of Trolox standard or extract, the absorbance reading at 734 nm was taken 6 min after initial mixing using an Infinite 200 Pro plate reader (Tecan, Männedorf, Switzerland). The percentage inhibition of absorbance at 734 nm was calculated and plotted as a function of the concentration of Trolox, and the TEAC value expressed as Trolox equivalents (μmol)/g of film using Magellan v7.2 software.

Characterization of Phenol Molecules

The phenolic fractions both from grape skin pomace film extracts and from migration test in aqueous simulant were separated and quantified through RP-HPLC. RP-HPLC analysis was performed using an Agilent-1100 liquid chromatograph equipped with a DAD detector, the separation was performed on C18 column (5 UltraSphere rum spherical 80 A pore, 25 mm), as described by Gerardi et al. (2020). Chromatograms were acquired at 520, 280, 320, 370 and 306 nm. The chromatographic analysis was based on the comparison of peak retention time with the retention time and UV vis spectra of external standards.

Structural Film Characterization

Scanning electron microscopy (SEM) on the cross-sections of composites was performed using a Phenom ProX microscope, working in high-vacuum mode. Before the analysis, samples with dimension 0.5 × 0.5 cm2 were prepared by fracturing the films in liquid nitrogen and sputter coated with a thin film of gold.

Film density was evaluated according the Eq. 1:

where A is the film area, λ the film thickness (cm), m the film dry mass (g) and ρs the dry matter density of the film (g/cm3) [48]. Each sample was firstly dried in a vacuum oven for 24 h before conditioning them in a desiccator for 7 days. The film density was evaluated as the average of three measurements.

Thermogravimetric analyses (TGA) were carried out in air atmosphere with a Mettler TC-10 thermobalance from 30 °C to 600 °C and setting a heating rate of 10 °C/min.

Differential scanning calorimetry (DSC) were carried out using a thermal analyzer Mettler DSC 822/400 under air atmosphere from 25 to 250 °C at a heating rate of 10 °C/min followed by an isotherm at 250 °C for a period of 60 min.

Mechanical properties were analyzed by means of a dynamometric apparatus INSTRON 4301 in displacement control with a rate of 1 mm/min using a cell load of 100 N. Experiments were conducted at room temperature. Results were averaged on quintuplicates.

Solubility (SOL) of the pomace films was evaluated according to the method described in the literature [49, 50]. Composite films were cut to obtain a 1 cm × 1 cm squares. Each specimen was weighed and immersed into a beaker with 50 mL of distilled water. The beaker was sealed to avoid water evaporation and stored at 25 °C for 24 h under mechanical agitation (350 rpm). After 24 h, the samples were removed from the beaker and dried in vacuum oven at 40 °C. SOL (%) was evaluated as (Eq. 2):

where M0 and M1 were the dry sample weight before and after the test, respectively. Results were reported as average values of quintuplicates.

Barrier properties of water vapor were evaluated through a DVS automated multi-vapor gravimetric sorption analyzer, using dry nitrogen as a carrier gas. The temperature was fixed to 30 °C. Samples were exposed to increasing water vapor pressures obtaining different water activities aw = P/P0 (from aw = 0.1 to aw = 0.8), where P is the partial pressure in the gravimetric chamber, and P0 is the saturation water pressure at the experimental temperature. The adsorbed water mass was measured by a microbalance and recorded as a function of time.

Contact angle measurements were performed using a high-resolution camera by putting a droplet on the sample surface (1 × 1 cm2). The contact angle was evaluated using Drop Analysis software. Five contact angle measurements were recorded to calculate the mean values ± standard deviations.

Statistical Analysis

The statistical significance of the obtained data was assessed by performing a one-way ANOVA test. Tukey’s post hoc method was carried out for assessing significant differences between means (p < 0.05). The statistical comparisons were obtained by means of the SigmaStat software (Version 11.0 Systat Software Inc., Chicago, IL).

Results and Discussion

Evaluation of Physical Properties of Films

Figure 1 reports the two wine pomaces and the pomace based films (b).

Concerning the density, FPF presents a higher density compared to NPF (about 30% higher). The higher density of the FPF, derived from white skin grapes, could be attributed to the higher content of soluble sugars, especially mono- or di-saccharides whose relatively high molecular weight could be responsible of the density increase [51]. The estimated film density values are reported in Table 1.

Figure 2 shows the two SEM pictures of FPF (a) and NPF (b). It could be observed that the produced films appeared quite homogeneous with some local cracks but no evident accumulation of material. The cross section images (Fig. 2c and d) show the presence of wrinkles and galleries whose presence was expected since the heterogeneous nature of the raw materials.

In Fig. 3a the thermogravimetric curves of the two pomace films in oxidative atmosphere are reported.

The thermogravimetric curves of the two samples were not significantly different. The first decomposition step is related to the moisture evaporation (5% wt for NPF and 10% wt for FPF). The higher content of water in NPF might be associated to the higher content of hydrolysable tannins and hydrophilic components such as hemicellulose and fibers. Below 200 °C, thermal decomposition of low molecular weight products such as glucans and xylans occurred [52]. The main thermal event involved the range 200 °C up to 400 °C and could be attributed to the thermal decomposition of pectin, cellulose, hemicellulose and dietary fibers [53]. The last thermal interval involves the final decomposition of lignin and the formation of char. The relatively high ash content of NPF is an indication of the presence of high amino acids and minerals concentration in the sample of red wine pomace.

Figure 3b reports the isothermal curves obtained from DSC analysis heating the samples at 250 °C for 60 min. The strong exothermic peaks obtained in heat flow curves could be related to the polymer crystallization. It was clear that the necessary time for maximum crystallization is about 18 min for NPF while the crystallization of FPF required a longer time.

The mechanical characterization was performed on both films. The stress–strain curves (Fig. 4) allowed to extrapolate the mechanical parameters: the elastic modulus, E (MPa), the stress at the break point, σbreak (MPa), and the elongation at break, εbreak (mm/mm%). Results obtained from the mechanical characterization displayed similar behavior in terms of mechanic performances. The elastic modulus, evaluated from the initial linear part of the stress–strain curves is 20.5 MPa for FPF and 6.5 MPa for NPF. Then, the elongation at break point is 20.6% for FPF and 25.2% for NPF. FPF appears to be more brittle than NPF and this result could be ascribed to the presence of local disconnection points inside the composite since the presence of a heterogeneous material, as evidenced in SEM images. Finally, the stress at break point is 1.13 MPa and 0.58 MPa for FPF and NPF, respectively.

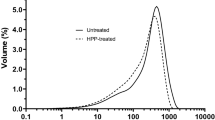

Figure 5 shows the sorption isotherms of pomace films (a) and the diffusion coefficient as log (D) plotted against of the equilibrium moisture content (Ceq, g/g on d.b.).

The sorption isotherm shape is a typical type II, according to Brunauer classification [54]. The Peleg model (Eq. 3) was applied to fit the experimental sorption data. This model was already applied to adequately describe the moisture sorption isotherms of some food stuff [55].

where qe is the amount of the adsorbate at equilibrium (g/g), ci are constants to be determined. The Peleg model fitting the experimental data is reported in Fig. 5a as a dashed line.

Peleg model gave acceptable fitting for representing the relationship between the equilibrium moisture content and water activity (Table 2). At low aw, the water sorption process occurs on available polar sites of grape pomaces while no differences could be observed for aw < 0.4 proving that the two kinds of pomaces are quite similar in terms of composition. For higher aw, the plasticization due to water and the increase of segmental motion led to an increase in the adsorbed moisture. Since water absorption is largely correlated to the water-soluble components, the higher adsorbed moisture content of NPF, which is reflected in the increase in sorption coefficient, could be associated to the massive presence in red grapes of hydrolysable tannins and hygroscopic matter such as pectin, cellulose, hemicellulose and fibers. The sorption parameter was then evaluated by calculating the derivative of equilibrium moisture content (M) respect to the partial pressure (P) (Eq. 4):

The diffusion coefficient can be estimated by applying the Fick’s second law solution. From the mass transfer balance, the Fick’s second law is represented by Eq. 5:

where x is the spatial coordinate. The solution of Eq. 5 is Eq. 6 [56]:

where Ci is the initial concentration inside the sample, Ceq is the maximum saturation concentration, d is the characteristic length of the sample, and D (cm2/s) the diffusion coefficient. To evaluate the penetrant concentration at the time t, the above Eq. 6 can be integrated over length x (Eq. 7):

with mi = initial mass of moisture and meq = mass of moisture when saturation is reached. From Eq. 8, it is possible to derive the water permeability coefficients reported in Table 2

It is interesting to note that the D0 coefficient of NPF is about 2 order of magnitude higher than FPF. As water activity increases, a slight increase in diffusion can be observed for NPF while a more accentuated increase was observed for FPF.

Solubility of composites respect to water is a fundamental parameter to be determined for possible applications of biopolymer films [57]. The pomace films solubility, reported in Table 3, was 67% for FPF and 72% for NPF. Usually, the total soluble sugars, condensed tannins (proanthocyanidins, polyflavonoid tannins) and soluble polyphenols in red grape is higher than white grape [38]. The solubilization of these substances in an aqueous medium could justify the higher solubility value of NPF than FPF. The hydrophilicity, evaluated through the contact angle (CA) measurements (Table 3), perfectly reflects the above reported considerations related to the chemical composition of red and white grape which affect the hydrophilicity of the surface of the fabricate films. In fact, the CA of NPF is lower than FPF proving a better affinity for water molecules ascribable to its main components.

Phenol Profile and Antioxidant Activity of Films

One of the main challenges in the field of packaging is the development of both renewable and biodegradable materials [58]. This trend toward the circular economy in the field of materials science has increased the interest in the valorization of food processing waste, which represent a rich source of bioactive compounds [59]. Furthermore, the incorporation of biomolecules to improve the functional properties of the film contributes to reduce the use of chemical synthetized compounds, which is of great importance for some applications, such as those related to food packaging [60]. The analysis of natural biomolecules such as phenolic molecules in films obtained by utilizing skins isolated from grape pomace of Fiano and Negroamaro cultivars is showed in Table 4.

Fiano skin grape pomace film (FPF) show an increase of extractable quercetin, kaempferol and caftaric acid related to the increase of processing temperature; while gallic acid, catechin, kaempferol-3-O-glucoside and total anthocyanins content does not significantly change as the temperature increase. Negroamaro skin grape pomace film (NPF) show an increase of extractable quercetin and a net decrease of total anthocyanins linked to the increase of temperature (from 20 to 100 °C). The content of remaining identified polyphenolic molecules remain stable. Total phenol content of the extracts from films obtained by both FPF and NPF do not showed any significant difference at different processing temperatures. Extracts from NPF showed a higher phenol concentration in comparison to films obtained from Fiano pomace (Fig. 6). Antioxidant activity of extracts from film follows the same trend described for total phenol content (Fig. 6).

Antioxidant activity (TEAC) expressed as mg Trolox Equivalents per gram of film disk and Total Phenols content expressed as mg Gallic Acid Equivalents per gram of sample films obtained at different temperatures (FPF and NPF) extracted in acidified organic solvents. Data are the mean ± standard deviation of three independent replicates (n = 3). Different letters indicate significant differences (p < 0.05) in total phenol content or antioxidant activity

Migration Tests

Results of the characterization by RP-HPLC separation of phenolic molecules released from FPF and NPF obtained at 20 °C in a medium that could simulate aqueous food, are reported in Table 5.

The water migration test can simulate the release of phenolic molecules when in contact with high water content foods, such as peeled fruit, salad, and other ready-to-eat fresh products. Negroamaro skin pomace film released a significantly higher amount of caffeic acid, caftaric acid, coutaric acid, quercetin and total anthocyanins when compared to Fiano skin pomace film that released a higher amount of catechin (Table 5). The comparison between the phenolic molecule compositions of the films obtained at 20 °C reported in Table 4 and the phenolic molecules released in the aqueous medium highlights that soluble acids (gallic acid, caffeic acid, caftaric acid, coutaric acid) and catechin are released in higher amounts in migration test conditions than during solvent extraction conditions. Flavonols such as kaempferol, kaempferol-3-O-glucoside, quercetin was not detectable in the medium simulating aqueous food and anthocyanins showed a lower amount or a less stability in migration test condition (Table 5).

Total phenol assay indicates a not significantly different release between FPF and NPF samples (Fig. 7) and comparing total polyphenol (TP) content in solvent extract and in aqueous food simulant medium we obtained a percentage of polyphenol migration of about 99% for Fiano and 77% for Negroamaro films. GP skins are rich in polyphenols, which are proven having antimicrobial functions through different mechanisms [21, 61]. In addition, GP is abundant in organic acids that have antibacterial activity against both Gram-negative and Gram-positive bacteria [21]. In this study, the released polyphenols together with organic acids from the skin pomace films could both play the roles as antibacterial agents.

Antioxidant activity (TEAC) expressed as mg Trolox Equivalents per gram of film disk and Total Phenols expressed as mg Gallic Acid Equivalents per gram of film disk, released in aqueous food simulant from FGPD and NGPD obtained at 20 °C. Data are the mean ± standard deviation of three independent replicates (n = 3). Different letters indicate significant differences (p < 0.05) in total phenol content or antioxidant activity

TEAC assay results reported in Fig. 7 showed that molecules migrated from film, in to the aqueous medium have similar antioxidant capacity of those in the solvent extract, higher for NPF than for FPF.

Concluding Remarks

The use of wine grape pomaces from two wine making processes opens the route to the fabrication of novel films potentially usable for food packaging applications. The fabricated films appeared quite similar in terms of morphological and thermal properties. Separated skin pomaces from Negroamaro (red) and Fiano (white) grape by-products were characterized for their polyphenols content and antioxidant activities in order to exploit them as source of polyphenols for industrial applications. The characterization of phenolic composition of fabricated films confirmed the peculiarity of some compounds such as anthocyanins in red skin pomace film (NPF) and a great amount of flavanols (Tables 4 and 5) in white skin pomace film (FPF). Antioxidant activity of polyphenols resulted in active films and was confirmed in migration test with aqueous food simulants (Figs. 4 and 5). Besides, Fiano film showed to possess a higher elastic modulus (20.5 MPa) compared to Negroamaro film (6.5 MPa) and lower diffusion coefficients (2.22 10–5 cm2/s and 8.85 10–4 cm2/s for Fiano and Negroamaro films, respectively). Solubility and water angle contact values are perfectly in agreement with the chemical composition of two wine pomaces. In this work, biofilms were produced using grape skin pomace directly as raw material instead of extracts in accordance with the principles of sustainability and circular economy. Several aspects are worthy further studies. Moreover, it is highlighted the use of wine making by-products as sourced for new low-cost materials with high performances. The systems appear very promising in the active packaging field since the fabricated materials are intrinsically antioxidant.

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

Change history

22 September 2022

Missing Open Access funding information has been added in the Funding Note.

References

Sganzerla WG, Rosa GB, Ferreira ALA et al (2020) Bioactive food packaging based on starch, citric pectin and functionalized with Acca sellowiana waste by-product: characterization and application in the postharvest conservation of apple. Int J Biol Macromol 147:295–303. https://doi.org/10.1016/J.IJBIOMAC.2020.01.074

Azeredo HMC, Rosa MF, Mattoso LHC (2017) Nanocellulose in bio-based food packaging applications. Ind Crops Prod 97:664–671. https://doi.org/10.1016/J.INDCROP.2016.03.013

Espitia PJP, Du WX, Avena-Bustillos RJ et al (2014) Edible films from pectin: physical-mechanical and antimicrobial properties—a review. Food Hydrocoll 35:287–296. https://doi.org/10.1016/J.FOODHYD.2013.06.005

Azeredo HMC (2009) Nanocomposites for food packaging applications. Food Res Int 42:1240–1253. https://doi.org/10.1016/J.FOODRES.2009.03.019

Fabra MJ, Jiménez A, Atarés L et al (2009) Effect of fatty acids and beeswax addition on properties of sodium caseinate dispersions and films. Biomacromol 10:1500–1507. https://doi.org/10.1021/BM900098P

Rojas-Lema S, Torres-Giner S, Quiles-Carrillo L et al (2020) On the use of phenolic compounds present in citrus fruits and grapes as natural antioxidants for thermo-compressed bio-based high-density polyethylene films. Antioxidants 10:14. https://doi.org/10.3390/ANTIOX10010014

Luzi F, Torre L, Puglia D (2020) Antioxidant packaging films based on ethylene vinyl alcohol copolymer (EVOH) and caffeic acid. Molecules 25:3953. https://doi.org/10.3390/MOLECULES25173953

Sogut E, Seydim AC (2018) The effects of Chitosan and grape seed extract-based edible films on the quality of vacuum packaged chicken breast fillets. Food Packag Shelf Life 18:13–20. https://doi.org/10.1016/J.FPSL.2018.07.006

Contini C, Álvarez R, O’Sullivan M et al (2014) Effect of an active packaging with citrus extract on lipid oxidation and sensory quality of cooked turkey meat. Meat Sci 96:1171–1176. https://doi.org/10.1016/J.MEATSCI.2013.11.007

Ezati P, Rhim JW (2021) Fabrication of quercetin-loaded biopolymer films as functional packaging materials. ACS Appl Polym Mater 3:2131–2137. https://doi.org/10.1021/ACSAPM.1C00177/SUPPL_FILE/AP1C00177_SI_001.PDF

Rambabu K, Bharath G, Banat F et al (2019) Mango leaf extract incorporated chitosan antioxidant film for active food packaging. Int J Biol Macromol 126:1234–1243. https://doi.org/10.1016/J.IJBIOMAC.2018.12.196

Gaikwad KK, Lee JY, Lee YS (2016) Development of polyvinyl alcohol and apple pomace bio-composite film with antioxidant properties for active food packaging application. J Food Sci Technol 53:1608–1619. https://doi.org/10.1007/S13197-015-2104-9/FIGURES/9

Roy S, Rhim JW (2020) Carboxymethyl cellulose-based antioxidant and antimicrobial active packaging film incorporated with curcumin and zinc oxide. Int J Biol Macromol 148:666–676. https://doi.org/10.1016/J.IJBIOMAC.2020.01.204

Hafeez MA, Maan AA, Butt MS, Zia MA (2021) Development and characterization of biodegradable food packaging films from food industrial wastes. Pakistan J Agric Sci 58:609–619. https://doi.org/10.21162/PAKJAS/21.1094

Brianceau S, Turk M, Vitrac X, Vorobiev E (2015) Combined densification and pulsed electric field treatment for selective polyphenols recovery from fermented grape pomace. Innov Food Sci Emerg Technol 29:2–8. https://doi.org/10.1016/J.IFSET.2014.07.010

Atencio S, Bernaerts T, Liu D et al (2021) Impact of processing on the functionalization of pumpkin pomace as a food texturizing ingredient. Innov Food Sci Emerg Technol 69:102669. https://doi.org/10.1016/J.IFSET.2021.102669

Otoni CG, Avena-Bustillos RJ, Azeredo HMC et al (2017) Recent advances on edible films based on fruits and vegetables—a review. Compr Rev Food Sci Food Saf 16:1151–1169. https://doi.org/10.1111/1541-4337.12281

Babbar N, Oberoi HS, Uppal DS, Patil RT (2011) Total phenolic content and antioxidant capacity of extracts obtained from six important fruit residues. Food Res Int 44:391–396. https://doi.org/10.1016/J.FOODRES.2010.10.001

Andrade RMS, Ferreira MSL, Gonçalves ÉCBA (2016) Development and characterization of edible films based on fruit and vegetable residues. J Food Sci 81:E412–E418. https://doi.org/10.1111/1750-3841.13192

Kaya S, Maskan A (2003) Water vapor permeability of pestil (a fruit leather) made from boiled grape juice with starch. J Food Eng 57:295–299. https://doi.org/10.1016/S0260-8774(02)00326-6

Deng Q, Zhao Y (2011) Physicochemical, nutritional, and antimicrobial properties of wine grape (cv. Merlot) pomace extract-based films. J Food Sci 76:E309–E317. https://doi.org/10.1111/J.1750-3841.2011.02090.X

Han JH, Aristippos G (2005) Edible films and coatings: a review. Innov Food Packag. https://doi.org/10.1016/B978-012311632-1/50047-4

Othman SH, Edwal SAM, Risyon NP et al (2017) Water sorption and water permeability properties of edible film made from potato peel waste. Food Sci Technol 37:63–70. https://doi.org/10.1590/1678-457X.30216

Gupta HHMAKASJ-W (2020) Synthesis of biodegradable films obtained from rice husk and sugarcane bagasse to be used as food packaging material. Environ Eng Res 25:506–514. https://doi.org/10.4491/EER.2019.191

Urbina L, Eceiza A, Gabilondo N et al (2019) Valorization of apple waste for active packaging: multicomponent polyhydroxyalkanoate coated nanopapers with improved hydrophobicity and antioxidant capacity. Food Packag Shelf Life 21:100356. https://doi.org/10.1016/J.FPSL.2019.100356

Thivya P, Bhosale YK, Anandakumar S et al (2021) Development of active packaging film from sodium alginate/carboxymethyl cellulose containing shallot waste extracts for anti-browning of fresh-cut produce. Int J Biol Macromol 188:790–799. https://doi.org/10.1016/J.IJBIOMAC.2021.08.039

Yadav A, Kumar N, Upadhyay A et al (2021) Edible packaging from fruit processing waste a comprehensive review. Food Rev Int. https://doi.org/10.1080/8755912920211940198

Lima EMB, Lima AM, Minguita APS et al (2019) Poly(lactic acid) biocomposites with mango waste and organo-montmorillonite for packaging. J Appl Polym Sci 136:47512. https://doi.org/10.1002/APP.47512

Zhong OX, Ismail H, Aziz NAA, Bakar AA (2011) Preparation and properties of biodegradable polymer film based on polyvinyl alcohol and tropical fruit waste flour. Polym Plast Technol 50:705–711. https://doi.org/10.1080/03602559.2010.551391

Sarebanha S, Farhan A (2018) Eco-friendly composite films based on polyvinyl alcohol and jackfruit waste flour. J Packag Technol Res 23(2):181–190. https://doi.org/10.1007/S41783-018-0043-4

García AV, Serrano NJ, Sanahuja AB, Garrigós MC (2020) Novel antioxidant packaging films based on poly(ε-caprolactone) and almond skin extract: development and effect on the oxidative stability of fried almonds. Antioxidants 9:629. https://doi.org/10.3390/ANTIOX9070629

Deshwal GK, Alam T, Panjagari NR (2021) Bhardwaj A (2021) Utilization of cereal crop residues, cereal milling, sugarcane and dairy processing by-products for sustainable packaging solutions. J Polym Environ 297(29):2046–2061. https://doi.org/10.1007/S10924-020-02034-W

Filippi K, Georgaka N, Alexandri M et al (2021) Valorisation of grape stalks and pomace for the production of bio-based succinic acid by Actinobacillus succinogenes. Ind Crops Prod 168:113578. https://doi.org/10.1016/J.INDCROP.2021.113578

Katalinić V, Možina SS, Skroza D et al (2010) Polyphenolic profile, antioxidant properties and antimicrobial activity of grape skin extracts of 14 Vitis vinifera varieties grown in Dalmatia (Croatia). Food Chem 119:715–723. https://doi.org/10.1016/J.FOODCHEM.2009.07.019

Gerardi C, D’amico L, Migoni D et al (2020) Strategies for reuse of skins separated from grape pomace as ingredient of functional beverages. Front Bioeng Biotechnol. https://doi.org/10.3389/FBIOE.2020.00645

Haas ICS, Toaldo IM, Burin VM, Bordignon-Luiz MT (2018) Extraction optimization for polyphenolic profiling and bioactive enrichment of extractives of non-pomace residue from grape processing. Ind Crops Prod 112:593–601. https://doi.org/10.1016/J.INDCROP.2017.12.058

Dwyer K, Hosseinian F, Rod M (2014) The market potential of grape waste alternatives. J Food Res. https://doi.org/10.5539/JFR.V3N2P91

García-Lomillo J, González-SanJosé ML (2017) Applications of wine pomace in the food industry: approaches and functions. Compr Rev Food Sci Food Saf 16:3–22. https://doi.org/10.1111/1541-4337.12238

Poudel PR, Tamura H, Kataoka I, Mochioka R (2008) Phenolic compounds and antioxidant activities of skins and seeds of five wild grapes and two hybrids native to Japan. J Food Compos Anal 21:622–625. https://doi.org/10.1016/J.JFCA.2008.07.003

Saurabh CK, Gupta S, Variyar PS (2018) Development of guar gum based active packaging films using grape pomace. J Food Sci Technol 556(55):1982–1992. https://doi.org/10.1007/S13197-018-3112-3

Ribeiro AB, Pinto RJB, Ferreira Nogueira G et al (2022) Development and characterization of arrowroot starch films incorporated with grape pomace extract. Polysaccharides 23:250–263. https://doi.org/10.3390/POLYSACCHARIDES3010014

Ferreira AS, Nunes C, Castro A et al (2014) Influence of grape pomace extract incorporation on chitosan films properties. Carbohydr Polym 113:490–499. https://doi.org/10.1016/J.CARBPOL.2014.07.032

Xu Y, Scales A, Jordan K et al (2017) Starch nanocomposite films incorporating grape pomace extract and cellulose nanocrystal. J Appl Polym Sci 134:44438. https://doi.org/10.1002/APP.44438

Genovese A, Gambuti A, Piombino P, Moio L (2007) Sensory properties and aroma compounds of sweet Fiano wine. Food Chem 103:1228–1236. https://doi.org/10.1016/J.FOODCHEM.2006.10.027

Marzano M, Fosso B, Manzari C et al (2016) Complexity and dynamics of the winemaking bacterial communities in berries, musts, and wines from apulian grape cultivars through time and space. PLoS ONE. https://doi.org/10.1371/journal.pone.0157383

Medina-Jaramillo C, Ochoa-Yepes O, Bernal C, Famá L (2017) Active and smart biodegradable packaging based on starch and natural extracts. Carbohydr Polym 176:187–194. https://doi.org/10.1016/J.CARBPOL.2017.08.079

Council Directive 85/572/EEC of 19 December 1985 laying down the list of simulants to be used for testing migration of constituents of plastic materials and articles intended to come into contact with foodstuffs - Publications Office of the EU. https://op.europa.eu/en/publication-detail/-/publication/bd664554-cb4a-4d7e-8e95-e36da6c900bf/language-en. Accessed 23 Oct 2021

Larotonda FDS, Matsui KN, Sobral PJA, Laurindo JB (2005) Hygroscopicity and water vapor permeability of Kraft paper impregnated with starch acetate. J Food Eng 71:394–402. https://doi.org/10.1016/j.jfoodeng.2004.11.002

Prakash Maran J, Sivakumar V, Thirugnanasambandham K, Sridhar R (2013) Response surface modeling and analysis of barrier and optical properties of maize starch edible films. Int J Biol Macromol 60:412–421. https://doi.org/10.1016/j.ijbiomac.2013.06.029

Romero-Bastida CA, Bello-Pérez LA, García MA et al (2005) Physicochemical and microstructural characterization of films prepared by thermal and cold gelatinization from non-conventional sources of starches. Carbohydr Polym 60:235–244. https://doi.org/10.1016/j.carbpol.2005.01.004

Deng Q, Penner MH, Zhao Y (2011) Chemical composition of dietary fiber and polyphenols of five different varieties of wine grape pomace skins. Food Res Int 44:2712–2720. https://doi.org/10.1016/J.FOODRES.2011.05.026

Zarrinbakhsh N, Wang T, Rodriguez-Uribe A et al (2016) Characterization of wastes and coproducts from the coffee industry for composite material production. BioResources 11:7637–7653. https://doi.org/10.15376/BIORES.11.3.7637-7653

Gowman A, Wang T, Rodriguez-Uribe A et al (2018) Bio-poly(butylene succinate) and its composites with grape pomace: mechanical performance and thermal properties. ACS Omega. https://doi.org/10.1021/acsomega.8b01675

Russel WW (1944) The adsorption of gases and vapors. Volume I: Physical adsorption (Brunauer, Stephen). J Chem Educ 21:52. https://doi.org/10.1021/ed021p52.1

Kaya S, Kahyaoglu T (2005) Thermodynamic properties and sorption equilibrium of pestil (grape leather). J Food Eng 71:200–207. https://doi.org/10.1016/J.JFOODENG.2004.10.034

Shen C-H, Springer GS (1976) Moisture absorption and desorption of composite materials. J Compos Mater 10:2–20. https://doi.org/10.1177/002199837601000101

Pattarasiriroj K, Kaewprachu P, Rawdkuen S (2020) Properties of rice flour-gelatine-nanoclay film with catechin-lysozyme and its use for pork belly wrapping. Food Hydrocoll 107:105951–105960. https://doi.org/10.1016/j.foodhyd.2020.105951

Pérez Córdoba LJ, Sobral PJA (2017) Physical and antioxidant properties of films based on gelatin, gelatin-chitosan or gelatin-sodium caseinate blends loaded with nanoemulsified active compounds. J Food Eng 213:47–53. https://doi.org/10.1016/J.JFOODENG.2017.05.023

Etxabide A, Uranga J, Guerrero P, de la Caba K (2017) Development of active gelatin films by means of valorisation of food processing waste: a review. Food Hydrocoll 68:192–198. https://doi.org/10.1016/J.FOODHYD.2016.08.021

Gutiérrez TJ, Ponce AG, Alvarez VA (2017) Nano-clays from natural and modified montmorillonite with and without added blueberry extract for active and intelligent food nanopackaging materials. Mater Chem Phys 194:283–292. https://doi.org/10.1016/J.MATCHEMPHYS.2017.03.052

Gerardi C, Durante M, D’Amico L, Tufariello M (2021) Re-use of grape pomace flour as new ingredient for pasta fortification

Acknowledgements

Project Prin 2017 "MultIFunctional poLymer cOmposites based on groWn matERials (MIFLOWER)" (grant number: 2017B7MMJ5_001) from the Italian Ministry of University and Research. This research was partially funded by ValBioVit-SNSvS NP-2.75 project- “2.2 Circular Economy” from MITE-Italy. The authors are grateful for technical support to D’Amico L., to Pascali A.M., and to Cantine Cantele for providing the grape pomaces.

Funding

Open access funding provided by Università degli Studi di Salerno within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Contributions

Conceptualization: Giuliana Gorrasi, Gianluca Viscusi, Carmela Gerardi and Giovanna Giovinazzo; formal analysis and investigation: Gianluca Viscusi, Elena Lamberti and Carmela Gerardi original draft preparation: Gianluca Viscusi and Giovanna Giovinazzo; writing—review and editing: Gianluca Viscusi, Carmela Gerardi, Giovanna Giovinazzo and Giuliana Gorrasi; funding acquisition: Giuliana Gorrasi and Giovanna Giovinazzo.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gorrasi, G., Viscusi, G., Gerardi, C. et al. Physicochemical and Antioxidant Properties of White (Fiano cv) and Red (Negroamaro cv) Grape Pomace Skin Based Films. J Polym Environ 30, 3609–3621 (2022). https://doi.org/10.1007/s10924-022-02463-9

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-022-02463-9