Abstract

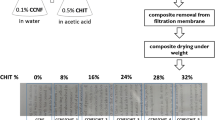

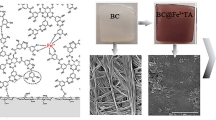

Hybrid cellulose nanocomposite films (HCNFs) were fabricated using cellulose from cotton linters as the matrix, and varying loadings (5 to 25wt.%) of modified tamarind nut power (TNP) with in situ generated copper nanoparticles as the reinforcing fillers. These hybrid composite films were characterized by X-ray diffraction (XRD), Fourier transform infrared (FTIR) spectroscopy, thermogravimetric analysis (TGA), and antibacterial tests. The inclusion of modified tamarind nut powder improved the crystallinity of the hybrid nanocomposites by 13%. From the FTIR analysis, it could be ascertained that there was no notable change in the chemical composition of the matrix with the amendment of the filler. Further, the shift in peak intensity with increasing concentration of the filler shows the formation of hydrogen bond between the filler and the matrix. The TGA analysis revealed that the degradation temperature of hybrid nanocomposites increased until HCNFs with 15wt.% modified tamarind nut powder. The hybrid nanocomposites exhibited better antibacterial properties against all the pathogens used in the study. These hybrid nanocomposites were found to have superior antibacterial activity, thermal resistance, and improvement in crystallinity. Thus, these bio-based materials can be used to replace the existing packaging materials in the food packaging and help to reduce the impact of conventional plastics on the environment.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Thiagamani SMK, Krishnasamy S, Siengchin S (2019) Challenges of biodegradable polymers: an environmental perspective. Appl Sci Eng Prog 12:149

Senthil Muthu Kumar T, Senthilkumar K, Chandrasekar M et al (2019) Characterization, thermal and dynamic mechanical properties of poly(propylene carbonate) lignocellulosic Cocos nucifera shell particulate biocomposites. Mater Res Express. https://doi.org/10.1088/2053-1591/ab2f08

Thiagamani SMK, Nagarajan R, Jawaid M et al (2017) Utilization of chemically treated municipal solid waste (spent coffee bean powder) as reinforcement in cellulose matrix for packaging applications. Waste Manag 69:445–454. https://doi.org/10.1016/j.wasman.2017.07.035

Thiagamani SMK, Rajini N, Siengchin S et al (2019) Influence of silver nanoparticles on the mechanical, thermal and antimicrobial properties of cellulose-based hybrid nanocomposites. Compos Part B Eng 165:516–525. https://doi.org/10.1016/j.compositesb.2019.02.006

Mamatha G, Varada Rajulu A, Madhukar K (2019) Development and analysis of cellulose nanocomposite films with in situ generated silver nanoparticles using tamarind nut powder as a reducing agent. Int J Polym Anal Charact 24:219–226

Indira Devi MP, Nallamuthu N, Rajini N et al (2019a) Biodegradable poly(propylene) carbonate using in-situ generated CuNPs coated Tamarindus indica filler for biomedical applications. Mater Today Commun 19:106–113. https://doi.org/10.1016/j.mtcomm.2019.01.007

Muthulakshmi L, Rajini N, Nellaiah H et al (2017) Preparation and properties of cellulose nanocomposite films with in situ generated copper nanoparticles using Terminalia catappa leaf extract. Int J Biol Macromol 95:1064–1071

Sadanand V, Rajini N, Varada Rajulu A, Satyanarayana B (2016) Preparation of cellulose composites with in situ generated copper nanoparticles using leaf extract and their properties. Carbohydr Polym 150:32–39. https://doi.org/10.1016/j.carbpol.2016.04.121

Sivaranjana P, Nagarajan ER, Rajini N et al (2018) Green synthesis of copper-reinforced cellulose nanocomposites for packaging applications. In: Jawaid M, Swain SK (eds) Bionanocomposites for packaging applications. Springer, Newyork, pp 179–189

Ashok B, Feng TH, Natarajan H, Anumakonda VR (2019) Preparation and characterization of tamarind nut powder with in situ generated copper nanoparticles using one-step hydrothermal method. Int J Polym Anal Charact 24:548–555. https://doi.org/10.1080/1023666X.2019.1626546

Kumar TSM, Rajini N, Tian H et al (2017) Development and analysis of biodegradable poly(propylene carbonate)/tamarind nut powder composite films. Int J Polym Anal Charact 22:415–423. https://doi.org/10.1080/1023666X.2017.1313483

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Sadanand V, Feng TH, Rajulu AV, Satyanarayana B (2017) Preparation and properties of low-cost cotton nanocomposite fabrics with in situ-generated copper nanoparticles by simple hydrothermal method. Int J Polym Anal Charact 22:587–594. https://doi.org/10.1080/1023666X.2017.1344916

Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES (2017) Effect of delignification on the physical, thermal, chemical, and structural properties of sugar palm fibre. BioResources 12:8734–8754

Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES (2019) Sugar palm nanofibrillated cellulose (Arenga pinnata (Wurmb.) Merr): effect of cycles on their yield, physic-chemical, morphological and thermal behavior. Int J Biol Macromol 123:379–388. https://doi.org/10.1016/j.ijbiomac.2018.11.124

Ilyas RA, Sapuan SM, Ibrahim R et al (2019) Sugar palm (Arenga pinnata (Wurmb.) Merr) cellulosic fibre hierarchy: a comprehensive approach from macro to nano scale. J Mater Res Technol 8:2753–2766. https://doi.org/10.1016/j.jmrt.2019.04.011

Ilyas RA, Sapuan SM, Ishak MR (2018) Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga Pinnata). Carbohydr Polym 181:1038–1051

Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES (2018) Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr Polym 202:186–202

Faix O (1992) Fourier transform infrared spectroscopy. In: Lin SY, Dence CW (eds) Methods in lignin chemistry. Springer, Berlin, pp 83–109

Fengel D, Ludwig M (1991) Possibilities and limits of FTIR spectroscopy characterization of the cellulose. Das Pap 45:45–51

Fan M, Dai D, Huang B (2012) Fourier transform—materials analysis. InTech, London

Sahari J, Sapuan SM, Ismarrubie ZN, Rahman MZA (2012) Physical and chemical properties of different morphological parts of sugar palm fibres. Fibres Text East Eur 91:21–24

Senthil Muthu Kumar T, Rajini N, Jawaid M et al (2018) Preparation and properties of cellulose/tamarind nut powder green composites: (green composite using agricultural waste reinforcement). J Nat Fibers 15:11–20. https://doi.org/10.1080/15440478.2017.1302386

Abral H, Basri A, Muhammad F et al (2019) A simple method for improving the properties of the sago starch films prepared by using ultrasonication treatment. Food Hydrocoll 93:276–283. https://doi.org/10.1016/j.foodhyd.2019.02.012

Nazar N, Bibi I, Kamal S et al (2018) Cu nanoparticles synthesis using biological molecule of P. granatum seeds extract as reducing and capping agent: growth mechanism and photo-catalytic activity. Int J Biol Macromol 106:1203–1210. https://doi.org/10.1016/j.ijbiomac.2017.08.126

Yallappa S, Manjanna J, Sindhe MA et al (2013) Microwave assisted rapid synthesis and biological evaluation of stable copper nanoparticles using T. arjuna bark extract. Spectrochim Acta - Part A Mol Biomol Spectrosc 110:108–115. https://doi.org/10.1016/j.saa.2013.03.005

Qi H, Cai J, Zhang L, Kuga S (2009) Properties of films composed of cellulose nanowhiskers and a cellulose matrix regenerated from alkali/urea solution. Biomacromolecules 10:1597–1602. https://doi.org/10.1021/bm9001975

Ilyas RA, Sapuan SM, Sanyang ML et al (2018) Nanocrystalline cellulose as reinforcement for polymeric matrix nanocomposites and its potential applications: a review. Curr Anal Chem 14:203–225. https://doi.org/10.2174/1573411013666171003155624

Saw SK, Datta C (2009) Thermomechanical properties of jute/bagasse hybrid fibre reinforced epoxy thermoset composites. BioResources 4:1455–1476. https://doi.org/10.15376/BIORES.4.4.1455-1475

Yang H, Yan R, Chen H et al (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Edhirej A, Sapuan SM, Jawaid M, Zahari NI (2017) Cassava/sugar palm fiber reinforced cassava starch hybrid composites: physical, thermal and structural properties. Int J Biol Macromol 101:75–83. https://doi.org/10.1016/j.ijbiomac.2017.03.045

Indira Devi MP, Nallamuthu N, Rajini N et al (2019b) Antimicrobial properties of poly(propylene) carbonate/Ag nanoparticle-modified tamarind seed polysaccharide with composite films. Ionics (Kiel). https://doi.org/10.1007/s11581-019-02895-9

Chatterjee AK, Chakraborty R, Basu T (2014) Mechanism of antibacterial activity of copper nanoparticles. Nanotechnology 25:135101

Acknowledgements

The work was financially supported by King Mongkut’s University of Technology North Bangkok (KMUTNB), Thailand, through grant no. KMUTNB-BasicR-64-16.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, T.S.M., Chandrasekar, M., Senthilkumar, K. et al. Characterization, Thermal and Antimicrobial Properties of Hybrid Cellulose Nanocomposite Films with in-Situ Generated Copper Nanoparticles in Tamarindus indica Nut Powder. J Polym Environ 29, 1134–1142 (2021). https://doi.org/10.1007/s10924-020-01939-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01939-w