Abstract

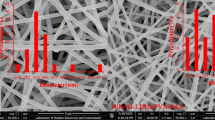

Wastewater treatment is one of the focuses in current society, and the removal of heavy metal ions from it is crucial in wastewater treatment. Polyvinyl alcohol (PVA) nanofibers play a certain role in the adsorption of heavy metal ions, but their adsorption capacity is limited. In this work, maleic anhydride (MAH) was first grafted onto the molecular chain of PVA. Then through the condensation of the carboxyl group and the amino group, the octaamino-POSS was successfully grafted on the PVA molecular chain. Two kinds of nanofibers, PVA/octaamino-POSS nanofibers as well as PVA-g-POSS nanofibers, were fabricated by electrospinning technology for the adsorption of Pb2+ and Cu2+ in wastewater. The preparation of PVA/octaamino-POSS was used to compare which metal ion adsorption process was more stable, physical blending or chemical grafting. With the increase of contact time, the adsorption capacity of PVA/octaamino-POSS nanofibers to Cu2+ increased at first and then decreased. It was observed that the adsorption capacity of PVA-g-POSS to heavy metal ions was higher than that of PVA/octaamino-POSS. With the increase of octaamino-POSS content, the equilibrium adsorption of Pb2+ and Cu2+ on PVA-g-POSS nanofibers was significantly improved, with prominent adsorption effect for Cu2+. Based on the analysis of quasi-first-order and quasi-second-order dynamic equation, it was deduced that the chemical adsorption and physical adsorption worked together in the adsorption process of Pb2+ and Cu2+ by PVA-g-POSS, and chemical adsorption played a major role.

Similar content being viewed by others

References

Sherlala A, Raman A, Bello M, Asghar A (2018) Chemosphere 193:1004–1017

Peydayesh M, Bolisetty S, Mohammadi T, Mezzenga R (2019) Langmuir 35:4161–4170

Gandavadi D, Sundarrajan S, Ramakrishna S (2019) Macromol Mater Eng 304:1900345

Huang YF, Wu DH, Wang XD, Huang W, Lawless D, Feng XS (2016) Sep Purif Technol 158:124–136

Kobya M, Demirbas E, Senturk E, Ince M (2005) Bioresour Technol 96:1518–1521

Lo S-F, Wang S-Y, Tsai M-J, Lin L-D (2012) Chem Eng Res Des 90:1397–1406

Godwin P, Pan Y, Xiao H, Afzal M (2019) J Bioresour Bioprod 4:31–42

Kadirvelu K, Thamaraiselvi K, Namasivayam C (2001) Bioresour Technol 76:63–65

Wu RP (2019) Ekoloji 28:2443–2452

Fu F, Wang Q (2011) J Environ Manage 92:407–418

Zhang M, Zhang L, Tian H, Lu A (2020) Carbohydr Polym 116037

Hemamalini T, Dev VRG (2018) Int J Biol Macromol 106:712–718

Pokorny M, Novak J, Rebicek J, Klemes J, Velebny V (2015) Nanomater Nanotechnol 5:17

Peng Q, Cheng J, Lu S, Li Y (2020) Polym Adv Technol 31:15–24

Ding B, Kim HY, Lee SC, Shao CL, Lee DR, Park SJ, Kwag GB, Choi KJ (2002) J Polym Sci Part B 40:1261–1268

Haider S, Park S-Y (2009) J Membr Sci 328:90–96

Li JL, Chen XY, Xu DF, Pan K (2019) Ecotoxicol Environ Saf 170:716–721

Cai N, Han C, Luo XG, Chen G, Dai Q, Yu FQ (2017) Macromol Mater Eng 302:10

Li K, Li C, Tian H, Yuan L, Xiang A, Wang C, Li J, Rajulu AV (2020) Macromol Mater Eng 305:8

Chen S, Li CP, Hou TT, Cai Y, Liang LM, Chen LM, Li MS (2019) React Funct Polym 145:11

Wu SJ, Li FT, Xu R, Wei SH, Wang HT (2010) Mater Lett 64:1295–1298

Jean JH, Lin SC (1999) J Mater Res 14:2922–2928

Chao HE, Yun YU, Xingfang HU, Larbot A (2003) J Eur Ceram Soc 23:1457–1464

Galizia P, Maizza G, Galassi C (2016) Process Appl Ceram 10:235–241

Hanaor DAH, Sorrell CC (2011) J Mater Sci 46:855–874

Ullah S, Hashmi M, Hussain N, Ullah A, Sarwar MN, Saito Y, Kim SH, Kim IS (2020) J Water Process Eng 33:101111

Truong YB, Choi J, Mardel J, Gao Y, Maisch S, Musameh M, Kyratzis IL (2017) Macromol Mater Eng 302:9

Huang H, Long M, Zhihan L, Yuejun L, Shuhong F, Yao J, Jianda X (2019) J Bioresour Bioprod 4:231–241

Esmaeili A, Beni AA (2014) J Hazard Mater 280:788–796

Duan B, Yuan X, Zhu Y, Zhang Y, Li X, Zhang Y, Yao K (2006) Eur Polym J 42:2013–2022

Mok CF, Ching YC, Muhamad F, Abu Osman NA, Hai ND, Hassan CRC (2020) J Polym Environ 28:775–793

Bavel E, Afkhami A, Madrakian T (2020) J Polym Environ 28:614–623

Kuo SW, Chang FC (2011) Prog Polym Sci 36:1649–1696

Phillips SH, Haddad TS, Tomczak SJ (2004) Curr Opin Solid State Mater Sci 8:21–29

Liu D, Yuan L, Xu H, Tian H, Xiang A (2019) Polym Compos 40:2768–2776

Li GZ, Wang LC, Ni HL, Pittman CU (2001) J Inorg Organomet Polym 11:123–154

Tanaka K, Chujo Y (2012) J Mater Chem 22:1733–1746

Tian H, Yuan L, Wang J, Wu H, Wang H, Xiang A, Ashok B, Rajulu AV (2019) J Hazard Mater 378:120751

Habiba U, Afifi AM, Salleh A, Ang BC (2017) J Hazard Mater 322:182–194

Kim U-J, Lee YR, Kang TH, Choi JW, Kimura S, Wada M (2017) Carbohydr Polym 163:34–42

Muller J, Prelot B, Zajac J, Monge S (2019) React Funct Polym 144:10

Pirzada T, Arvidson SA, Saquing CD, Shah SS, Khan SA (2012) Langmuir 28:5834–5844

Shooto ND, Dikio CW, Wankasi D, Sikhwivhilu LM, Mtunzi FM, Dikio ED (2016) Nanoscale Res Lett 11:1–13

Lagergren S, Lagergren S, Lagergren S, Sven K (1898) Veternskapsakad Handlingar 24:1–39

Ho Y-S, McKay G (1999) Process Biochem 34:451–465

He K, Chen YC, Tang ZH, Hu YY (2016) Environ Sci Pollut Res 23:2778–2788

Bartczak P, Norman M, Klapiszewski Ł, Karwańska N, Kawalec M, Baczyńska M, Wysokowski M, Zdarta J, Ciesielczyk F, Jesionowski T (2018) Arab J Chem 11:1209–1222

Acknowledgements

This work is dedicated to Professor Lina Zhang on her 80th birthday. This work was supported by Beijing Natural Science Foundation (2202014), School Level Cultivation Fund of Beijing Technology and Business University for Distinguished and Excellent Young Scholars (BTBUYP2020), and Funding of State Key Laboratory of Pulp and Paper Engineering, South China University of Technology (201801).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, Y., Tian, H., Xiang, A. et al. Fabrication of PVA Nanofibers Grafted with Octaamino-POSS and their Application in Heavy Metal Adsorption. J Polym Environ 29, 1566–1575 (2021). https://doi.org/10.1007/s10924-020-01865-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01865-x