Abstract

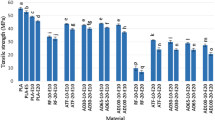

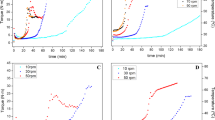

Bioplastics have gained great interest in recent years as a potential alternative to conventional plastics, since they are renewable and biodegradable materials. However, their mechanical properties are not able to match those of conventional plastics yet. In this context, the incorporation of additives to improve those properties of bioplastics is an interesting line of research. The aim of this work was to develop soy protein-based bioplastics with lignocellulosic fiber (additive) by injection molding. Mechanical and absorption properties of bioplastics reinforced with lignocellulose (0.1, 1.0, 5.0 wt%) have been studied, as well as their microstructure. Furthermore, a study of the effect produced by changing the mold temperature (70, 90, 110, 130 °C) was carried out. The results obtained confirm an improvement of the mechanical properties of these bioplastics, depending on the amount of fiber incorporated. In any case, these findings support the role of cellulosic compounds as additives in protein bioplastics.

Similar content being viewed by others

References

Plastics Europe (2016) An analysis of european plastics production, demand and waste data. http://www.plasticseurope.es/Document/plastics—the-facts-2016-15787.aspx?FollD=2. Accessed 11 Jun 2018

Hoornweg D, Bhada-Tata P, Kennedy C (2013) Environment: waste production must peak this century. Nature 502:615–617. https://doi.org/10.1038/502615a

Wilson DC, Rodic L, Modak P, et al (2015) Global waste management outlook: Summary for decision-makers. International Environmental Technology Centre (IETC) Division of Industry, Technology and Economics, UNEP, Japan

Remar (Red de Energía y Medio Ambiente) (2011) Introducción a los bioplásticos. Bioplásticos: Guía práctica—número 2. Remar, Madrid, pp 4–6

Tanrattanakul V, Saithai P (2009) Mechanical properties of bioplastics and bioplastic–organoclay nanocomposites prepared from epoxidized soybean oil with different epoxide contents. J Appl Polym Sci 114:3057–3067. https://doi.org/10.1002/app.30842

Sakunkittiyut Y, Kunanopparat T, Menut P, Siriwattanayotin S (2013) Effect of kraft lignin on protein aggregation, functional, and rheological properties of fish protein-based material. J Appl Polym Sci 127:1703–1710. https://doi.org/10.1002/app.37899

Jones A, Mandal A, Sharma S (2015) Protein-based bioplastics and their antibacterial potential. J Appl Polym Sci 132:41931. https://doi.org/10.1002/app.41931

Gonçalves I, Vasconcelos A, Machado ASL, Alves AV (2017) Bioplastics from agro-wastes for food packaging applications. In: Grumezescu AM (ed) Food packaging, 1st edn. Academic Press, Cambridge, pp 223–263

Verbeek CJR, Uitto JM (2017) Bioplastics. Encycl Polym Sci Technol. https://doi.org/10.1002/0471440264.pst654

Felix M, Perez-Puyana V, Romero A, Guerrero A (2017) Production and characterization of bioplastics obtained by injection moulding of various protein systems. J Polym Environ 25:91–100. https://doi.org/10.1007/s10924-016-0790-7

Guerrero P, Retegi A, Gabilondo N, De La Caba K (2010) Mechanical and thermal properties of soy protein films processed by casting and compression. J Food Eng 100:145–151. https://doi.org/10.1016/j.jfoodeng.2010.03.039

Tian H, Wang Y, Zhang L et al (2010) Improved flexibility and water resistance of soy protein thermoplastics containing waterborne polyurethane. Ind Crops Prod 32:13–20. https://doi.org/10.1016/j.indcrop.2010.02.009

Song F, Tang D-L, Wang X-L, Wang Y-Z (2011) Biodegradable soy protein isolate-based materials: a review. Biomacromolecules 12:3369–3380. https://doi.org/10.1021/bm200904x

Liu B, Jiang L, Zhang J (2010) Development of soy protein/poly (lacctic acid) bioplastics. In: Society of Plastic Engineers (ed) Global Plastics Environmental Conference

Félix M, Martín-Alfonso JE, Romero A, Guerrero A (2014) Development of albumen/soy biobased plastic materials processed by injection molding. J Food Eng 125:7–16. https://doi.org/10.1016/j.jfoodeng.2013.10.018

Zárate-Ramírez LS, Romero A, Bengoechea C et al (2014) Thermo-mechanical and hydrophilic properties of polysaccharide/gluten-based bioplastics. Carbohydr Polym 112:24–31. https://doi.org/10.1016/j.carbpol.2014.05.055

Felix M, Romero A, Cordobes F, Guerrero A (2014) Development of crayfish bio-based plastic materials processed by small-scale injection moulding. J Sci Food Agric 95:679–687. https://doi.org/10.1002/jsfa.6747

Adamy M, Verbeek CJR (2013) Injection-molding performance and mechanical properties of blood meal-based thermoplastics. Adv Polym Technol 32:1–9. https://doi.org/10.1002/adv.21361

Jansens KJA, Vo Hong N, Telen L et al (2013) Effect of molding conditions and moisture content on the mechanical properties of compression molded glassy, wheat gluten bioplastics. Ind Crops Prod 44:480–487. https://doi.org/10.1016/j.indcrop.2012.10.006

Beltrán M, Marcilla A (2015) Tecnología de polímeros. Procesado y propiedades. Universidad de Alicante, Alicante

Perez V, Felix M, Romero A, Guerrero A (2016) Characterization of pea protein-based bioplastics processed by injection moulding. Food Bioprod Process 97:100–108. https://doi.org/10.1016/j.fbp.2015.12.004

Fernández-Espada L, Bengoechea C, Cordobés F, Guerrero A (2016) Thermomechanical properties and water uptake capacity of soy protein-based bioplastics processed by injection molding. J Appl Polym Sci 133:43524. https://doi.org/10.1002/app.43524

Rendón-Villalobos JR, Solorza-Feria J, Rodríguez-González F, Flores-Huicochea E (2017) Barrier properties improvement using additives. In: Grumezescu AM (ed) Food packaging. Academic Press, Cambridge, pp 465–495

Felix M, Perez-Puyana V, Romero A, Guerrero A (2017) Development of protein-based bioplastics modified with different additives. J Appl Polym Sci 143:45430

Bourny V, Perez-Puyana V, Felix M et al (2017) Evaluation of the injection moulding conditions in soy/nanoclay based composites. Eur Polym J 95:539–546. https://doi.org/10.1016/j.eurpolymj.2017.08.036

Sun E, Liao G, Zhang Q et al (2019) Biodegradable copolymer-based composites made from straw fiber for biocomposite flowerpots application. Compos B 165:193–198. https://doi.org/10.1016/j.compositesb.2018.11.121

Sun E, Liao G, Zhang Q et al (2018) Green preparation of straw fiber reinforced hydrolyzed soy protein isolate/urea/formaldehyde composites for biocomposite flower pots application. Materials (Basel) 11:1695. https://doi.org/10.3390/ma11091695

Chensong D, Hitoshi T (2014) Flexural properties of cellulose nanofibre reinforced green composites. Compos Part B 58:418–421

Lubis M, Harahap MB, Ginting MHS et al (2018) Production of bioplastic from avocado seed starch reinforced with microcrystalline cellulose from sugar palm fibers. J Eng Sci Technol 13:381–393

Felix M, Carpintero V, Romero A, Guerrero A (2016) Influence of sorbitol on mechanical and physico-chemical properties of soy protein-based bioplastics processed by injection molding. Polímeros 26:277–281. https://doi.org/10.1590/0104-1428.0044

Tagi A, Askar KA, Nagy K et al (2011) Effect of different concentrations of olive oil and oleic acid on the mechanical properties of albumen (egg white) edible films. Afr J Biotechnol 10:12963–12972

Hosseini S, Ghiasi F, Jahromi M (2017) Nanocapsule formation by complexation of biopolymers. Nanoencapsul Technol Food Nutraceut Ind 2017:447–492

Orts WJ, Shey J, Imam SH et al (2005) Application of cellulose microfibrils in polymer nanocomposites. J Polym Environ 13:301–306. https://doi.org/10.1007/s10924-005-5514-3

Yano H, Nakahara S (2004) Bio-composites produced from plant microfiber bundles with a nanometer unit web-like network. J Mater Sci 39:1635–1638. https://doi.org/10.1023/B:JMSC.0000016162.43897.0a

Montaño-Leyva B, da Silva GGD, Gastaldi E et al (2013) Biocomposites from wheat proteins and fibers: structure/mechanical properties relationships. Ind Crops Prod 43:545–555. https://doi.org/10.1016/j.indcrop.2012.07.065

Page DH, El-Hosseiny F (1983) Mechanical properties of single wood pulp fibres. Part VI. Fibril angle and the shape of the stress-strain curve. J Pulp Pap Sci 9:99–100

Satyanarayana KG, Arizaga GGC, Wypych F (2009) Biodegradable composites based on lignocellulosic fibers—an overview. Prog Polym Sci 34:982–1021. https://doi.org/10.1016/j.progpolymsci.2008.12.002

Bennick A (2002) Interaction of plant polyphenols with salivary proteins. Crit Rev Oral Biol Med 13:184–196

Sarni-Manchado P, Cheynier V, Moutounet M (1999) Interactions of grape seed tannins with salivary proteins. J Agric Food Chem 47:42–47. https://doi.org/10.1021/jf9805146

Félix M, Lucio-Villegas A, Romero A, Guerrero A (2016) Development of rice protein bio-based plastic materials processed by injection molding. Ind Crop Prod 79:152–159. https://doi.org/10.1016/j.indcrop.2015.11.028

Fernández-Espada L, Bengoechea C, Cordobés F, Guerrero A (2016) Protein/glycerol blends and injection-molded bioplastic matrices: soybean versus egg albumen. J Appl Polym Sci 133:42980. https://doi.org/10.1002/app.42980

Dealy JM (1983) A practical guide to testing and property measurement. Vn Nostrand Reinhold Co., New York

Van Wazer JR, Lyons JW, Kim KY, Colwell RE (1963) A laboratory handbook of rheology. Interscience Publishers, New York

ISO 570-2:1993 (1993) Plastics. Determination of tensile properties. Part 2: Test conditions for moulding and extrusion plastics

ASTM D570-98 (2005) Standard test method for water absorption of plastics

Mohanty AK, Tummala P, Liu W et al (2005) Injection molded biocomposites from soy protein based bioplastic and short industrial hemp fiber. J Polym Environ 13:279–285. https://doi.org/10.1007/s10924-005-4762-6

Kunanopparat T, Menut P, Morel M-H, Guilbert S (2008) Plasticized wheat gluten reinforcement with natural fibers: effect of thermal treatment on the fiber/matrix adhesion. Compos A 39:1787–1792. https://doi.org/10.1016/j.compositesa.2008.08.006

Cuq B, Gontard N, Guilbert S (1998) Proteins as agricultural polymers for packaging production. Cereal Chem 75:1–9

Li Q, Liao G, Zhang S et al (2018) Effect of adjustable molecular chain structure and pure silica zeolite nanoparticles on thermal, mechanical, dielectric, UV-shielding and hydrophobic properties of fluorinated copolyimide composites. Appl Surf Sci 427:437–450. https://doi.org/10.1016/j.apsusc.2017.08.024

Li Q, Liao G, Tian J, Xu Z (2018) Preparation of novel fluorinated copolyimide/amine-functionalized sepia eumelanin nanocomposites with enhanced mechanical, thermal, and UV-shielding properties. Macromol Mater Eng 303:1700407. https://doi.org/10.1002/mame.201700407

Liao G, Chen J, Zeng W et al (2016) Facile preparation of uniform nanocomposite spheres with loading silver nanoparticles on polystyrene-methyl acrylic acid spheres for catalytic reduction of 4-nitrophenol. J Phys Chem C 120:25935–25944. https://doi.org/10.1021/acs.jpcc.6b09356

Liao G, Li Q, Zhao W et al (2018) In-situ construction of novel silver nanoparticle decorated polymeric spheres as highly active and stable catalysts for reduction of methylene blue dye. Appl Catal A Gen 549:102–111. https://doi.org/10.1016/j.apcata.2017.09.034

Mamun A, Nikousaleh MA, Feldmann M et al (2016) 8—Lignin reinforcement in bioplastic composites. In: Faruk O (ed) Lignin reinforcement in bioplastic composites. William Andrew Publishing, Amsterdam, pp 153–165

Nam S, Netravali AN (2004) Characterization of ramie fiber/soy protein concentrate (SPC) resin interface. J Adhes Sci Technol 18:1063–1076. https://doi.org/10.1163/1568561041257504

Kim J-K, Mai Y (1991) High strength, high fracture toughness fibre composites with interface control—a review. Compos Sci Technol 41:333–378. https://doi.org/10.1016/0266-3538(91)90072-W

Huang X, Netravali A (2009) Biodegradable green composites made using bamboo micro/nano-fibrils and chemically modified soy protein resin. Compos Sci Technol 69:1009–1015. https://doi.org/10.1016/j.compscitech.2009.01.014

Jerez A, Partal P, Martínez I et al (2005) Rheology and processing of gluten based bioplastics. Biochem Eng J 26:131–138. https://doi.org/10.1016/j.bej.2005.04.010

Bruyninckx K, Jansens KJA, Goderis B et al (2015) Removal of disulfide cross-links from wheat gluten and the effect thereof on the mechanical properties of rigid gluten bioplastic. Eur Polym J 68:573–584. https://doi.org/10.1016/j.eurpolymj.2015.03.047

Bruyninckx K, Jansens KJA, Delcour JA, Smet M (2016) The effect of cross-linking additives on the structure and properties of glassy wheat gluten material. Ind Crops Prod 81:38–48. https://doi.org/10.1016/j.indcrop.2015.11.049

Li Y, Xin S, Bian Y et al (2016) The physical properties of poly(l-lactide) and functionalized eggshell powder composites. Int J Biol Macromol 85:63–73. https://doi.org/10.1016/j.ijbiomac.2015.12.070

Paetau I, Chen CZ, Jane JL (1994) Biodegradable plastic made from soybean products. 1. Effect of preparation and processing on mechanical-properties and water-absorption. Ind Eng Chem Res 33:1821–1827. https://doi.org/10.1021/ie00031a023

Mo X, Sun XS, Wang Y (1999) Effects of molding temperature and pressure on properties of soy protein polymers. J Appl Polym Sci 73:2595–2602. https://doi.org/10.1002/(SICI)1097-4628(19990923)73:13%3c2595:AID-APP6%3e3.0.CO;2-1

Acknowledgements

This work is part of a Research Project sponsored by the Spanish Government “Ministerio de Economía y Competitividad” by the Grant Ref. CTQ2015-71164-P. The authors gratefully acknowledge their financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations'.

Rights and permissions

About this article

Cite this article

Gamero, S., Jiménez-Rosado, M., Romero, A. et al. Reinforcement of Soy Protein-Based Bioplastics Through Addition of Lignocellulose and Injection Molding Processing Conditions. J Polym Environ 27, 1285–1293 (2019). https://doi.org/10.1007/s10924-019-01430-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01430-1