Abstract

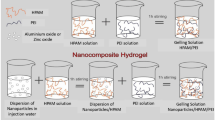

Polymeric hydrogels are designed to serve many purposes in various fields of human endeavor. Herein, crosslinked polyacrylamide (PAM) composite hydrogels impregnated with coal fly ash (CFA) were synthesized, characterized and tested as fracture sealing agents in high water producing permeable zones in petroleum industry. The concept of utilizing CFA as an inorganic additive in the matrix of hydrogel emanates from the fact that CFA constitutes majorly alumina and silica. Both chemical oxides can induce the CFA to promote the inherent properties of hydrogel. Polyethyleneimine (PEI) was chosen as the crosslinking agent. Neat PAM/PEI hydrogel and PAM/PEI–CFA hydrogels at various CFA loadings (0.5, 1 and 2 wt%) were synthesized via a transamidation reaction pathway. The developed hydrogels were characterized by hybrid rheometer, FTIR, SEM and XRD instruments. Rheological results reveal that the PAM/PEI–CFA composite hydrogels embedded with various CFA quantities were more elastic than the neat PAM/PEI hydrogel, indicating the dispersion and reinforcing effect of CFA. The functional groups of these hydrogels were confirmed by the FTIR while SEM analysis show that the surface micrographs of neat PAM/PEI hydrogel and PAM/PEI–CFA1 hydrogel were porous in several regions. In contrast, the micrographs of PAM/PEI–CFA2 and PAM/PEI–CFA3 hydrogels demonstrated dense and “net-like” structural patterns. Further, XRD analysis revealed that CFA impregnation has a significant effect on the bulk structural properties of the fabricated hydrogels. The swelling rates of these hydrogels were determined by the gravimetric method and their diffusion parameters evaluated using Fickian diffusion and Schott-order kinetic models. Efficacy of the PAM/PEI–CFA composite hydrogel as fractures sealant in oil and gas wells was conducted at a typical reservoir temperature, 90 °C, and the outcome demonstrated considerable sealing potency.

Similar content being viewed by others

References

Belviso C, Cavalcante F, Di S et al (2015) Mobility of trace elements in fly ash and in zeolitised coal fly ash. Fuel 144:369–379

García-maté M, De Torre AG, León-Reina L et al (2013) Hydration studies of calcium sulfoaluminate cements blended with fly ash. Cem Concr Res 54:12–20

Tkaczewska E (2014) Effect of size fraction and glass structure of siliceous fly ashes on fly ash cement hydration. J Ind Eng Chem 20:315–321

Morandeau A, Thiéry M, Dangla P (2015) Impact of accelerated carbonation on OPC cement paste blended with fl y ash. Cem Concr Res 67:226–236

Yang J, Han C-R, Duan J-F et al (2012) Synthesis and characterization of mechanically flexible and tough cellulose nanocrystals–polyacrylamide nanocomposite hydrogels. Cellulose 20:227–237. https://doi.org/10.1007/s10570-012-9841-y

Helvacıoğlu E, Aydın V, Nugay T et al (2011) High strength poly(acrylamide)-clay hydrogels. J Polym Res 18:2341–2350. https://doi.org/10.1007/s10965-011-9647-x

Agrawal A, Rahbar N, Calvert PD (2013) Strong fiber-reinforced hydrogel. Acta Biomater 9:5313–5318. https://doi.org/10.1016/j.actbio.2012.10.011

Bhattacharyya R, Ray SK (2015) Removal of congo red and methyl violet from water using nano clay filled composite hydrogels of poly acrylic acid and polyethylene glycol. Chem Eng J 260:269–283

Haraguchi K, Toru T (2002) Nanocomposite hydrogels: a unique organic network structure with extraordinary mechanical, optical, and swelling/de-swelling properties. Adv Mater 14:1120–1124

Liu Z, Lu A, Yang Z, Luo Y (2013) Enhanced swelling and mechanical properties of P(AM-co-SMA) semi-IPN composite hydrogels by impregnation with PANI and MWNTs-COOH. Macromol Res 21:376–384. https://doi.org/10.1007/s13233-013-1024-7

Okada A, Usuki A (2006) Twenty years of polymer-clay nanocomposites. Macromol Mater Eng 291:1449–1476. https://doi.org/10.1002/mame.200600260

Sharma RK, Puri A, Kumar A, Adholeya A (2013) Chemically modified silica gel with characterization and application as an e ffi cient and reusable solid phase extractant for selective removal of Zn(II) from mycorrhizal treated fly-ash samples. J Environ Sci 25:1252–1261. https://doi.org/10.1016/S1001-0742(12)60173-9

Sirousazar M, Kokabi M, Hassan ZM, Bahramian AR (2011) Mineral kaolinite clay for preparation of nanocomposite hydrogels. J Appl Polym Sci 125:E122–E130. https://doi.org/10.1002/app.35095

Tong X, Zheng J, Lu Y et al (2007) Swelling and mechanical behaviors of carbon nanotube/poly(vinyl alcohol) hybrid hydrogels. Mater Lett 61:1704–1706. https://doi.org/10.1016/j.matlet.2006.07.115

Uddin AJ, Araki J, Gotoh Y (2011) Characterization of the poly(vinyl alcohol)/cellulose whisker gel spun fibers. Compos A 42:741–747. https://doi.org/10.1016/j.compositesa.2011.02.012

Zhang X, Wang Y, Lu C, Zhang W (2014) Cellulose hydrogels prepared from micron-sized bamboo cellulose fibers. Carbohydr Polym 114:166–169. https://doi.org/10.1016/j.carbpol.2014.08.012

Fukui K, Kidoguchi S, Arimitsu N et al (2009) Synthesis of calcium phosphate hydrogel from waste incineration fly ash and its application to fuel cell. J Environ Manag 90:2709–2714. https://doi.org/10.1016/j.jenvman.2009.02.014

Fukui K, Arimitsu N, Jikihara K et al (2009) Performance of fuel cell using calcium phosphate hydrogel membrane prepared from waste incineration fly ash and chicken bone powder. J Hazard Mater 168:1617–1621. https://doi.org/10.1016/j.jhazmat.2009.02.119

Jiang L, Liu P (2014) Design of magnetic attapulgite/fly ash/poly(acrylic acid) ternary nanocomposite hydrogels and performance evaluation as selective adsorbent for Pb2+ ion. ACS Sustain Chem Eng 2:1785–1794. https://doi.org/10.1021/sc500031z

Suriano R, Griffini G, Chiari M et al (2014) Rheological and mechanical behavior of polyacrylamide hydrogels chemically crosslinked with allyl agarose for two-dimensional gel electrophoresis. J Mech Behav Biomed Mater 30:339–346. https://doi.org/10.1016/j.jmbbm.2013.12.006

Kenawy E-R (1998) Biologically active polymers: controlled-release formulations based on crosslinked acrylamide gel derivatives. React Funct Polym 36:31–39. https://doi.org/10.1016/S1381-5148(97)00095-3

Siddhanta SK, Gangopadhyay R (2005) Conducting polymer gel: formation of a novel semi-IPN from polyaniline and crosslinked poly(2-acrylamido-2-methyl propanesulphonicacid). Polymer 46:2993–3000. https://doi.org/10.1016/j.polymer.2005.01.084

Tang Q, Cai H, Yuan S et al (2013) Enhanced proton conductivity from phosphoric acid-imbibed crosslinked 3D polyacrylamide frameworks for high-temperature proton exchange membranes. Int J Hydrog Energy 38:1016–1026. https://doi.org/10.1016/j.ijhydene.2012.10.107

Duan J, Lu Q, Chen R et al (2010) Synthesis of a novel flocculant on the basis of crosslinked Konjac glucomannan-graft-polyacrylamide-co-sodium xanthate and its application in removal of Cu2+ ion. Carbohydr Polym 80:436–441. https://doi.org/10.1016/j.carbpol.2009.11.046

Guerrero A, Goñi S, Allegro VR (2009) Resistance of class C fly ash belite cement to simulated sodium sulphate radioactive liquid waste attack. J Hazard Mater 161:1250–1254. https://doi.org/10.1016/j.jhazmat.2008.04.086

Jia H, Zhao J, Jin F et al (2012) New insights into the gelation behavior of polyethyleneimine cross-linking partially hydrolyzed polyacrylamide gels. Ind Eng Chem Res 51:12155. https://doi.org/10.1021/ie301818f

Zhou C, Wu Q (2011) A novel polyacrylamide nanocomposite hydrogel reinforced with natural chitosan nanofibers. Colloids Surf B 84:155–162. https://doi.org/10.1016/j.colsurfb.2010.12.030

Peppas NA, Franson NM (1983) The swelling interface number as a criterion for prediction of diffusional solute release mechanisms in swellable polymers. J Polym Sci B 21:983–997. https://doi.org/10.1002/pol.1983.180210614

Huang Y, Zhang B, Xu G, Hao W (2013) Swelling behaviours and mechanical properties of silk fibroin–polyurethane composite hydrogels. Compos Sci Technol 84:15–22. https://doi.org/10.1016/j.compscitech.2013.05.007

Schott H (2006) Swelling kinetics of polymers. J Macromol Sci B. https://doi.org/10.1080/00222349208215453

Zhou C, Wu Q, Zhang Q (2010) Dynamic rheology studies of in situ polymerization process of polyacrylamide–cellulose nanocrystal composite hydrogels. Colloid Polym Sci 289:247–255. https://doi.org/10.1007/s00396-010-2342-3

Kamoun E, Menzel H (2012) HES-HEMA nanocomposite polymer hydrogels: swelling behavior and characterization. J Polym Res 19:1–14. https://doi.org/10.1007/s10965-012-9851-3

Long Y, Pu Z, Huang X et al (2014) Effect of CuPc@MWCNTs on rheological, thermal, mechanical and dielectric properties of polyarylene ether nitriles (PEN) terminated with phthalonitriles. J Polym Res 21:525. https://doi.org/10.1007/s10965-014-0525-1

Anderson KD, Lu D, McConney ME et al (2008) Hydrogel microstructures combined with electrospun fibers and photopatterning for shape and modulus control. Polymer 49:5284–5293. https://doi.org/10.1016/j.polymer.2008.09.039

Nair SS, Zhu JY, Deng Y, Ragauskas AJ (2014) Hydrogels prepared from cross-linked nano fibrillated cellulose. ACS Sustain Chem Eng 2:772–780

Jiang L, Liu P (2014) Covalently crosslinked fly ash/poly(acrylic acid-co-acrylamide) composite microgels as novel magnetic selective adsorbent for Pb2+ ion. J Colloid Interface Sci 426:64–71. https://doi.org/10.1016/j.jcis.2014.03.045

Zhao W, Shi Z, Chen X et al (2015) Microstructural and mechanical characteristics of PHEMA-based nanofibre-reinforced hydrogel under compression. Compos B 76:292–299. https://doi.org/10.1016/j.compositesb.2015.02.033

Huerta-angeles G, Hishchak K, Strachota A et al (2014) Super-porous nanocomposite PNIPAm hydrogels reinforced with titania nanoparticles, displaying a very fast temperature response as well as pH-sensitivity. Eur Polym J 59:341–352. https://doi.org/10.1016/j.eurpolymj.2014.07.033

Baybaş D, Ulusoy U (2012) Polyacrylamide-hydroxyapatite composite: preparation, characterization and adsorptive features for uranium and thorium. J Solid State Chem 194:1–8. https://doi.org/10.1016/j.jssc.2012.07.039

Liu J, Liu Y, Wu Z et al (2012) Polyethyleneimine functionalized protonated titanate nanotubes as superior carbon dioxide adsorbents. J Colloid Interface Sci 386:392–397. https://doi.org/10.1016/j.jcis.2012.07.048

Anandhan S, Sundar SM, Senthil T et al (2012) Extruded poly(ethylene-co-octene)/fly ash composites—value added products from an environmental pollutant. J Polym Res 19:9840. https://doi.org/10.1007/s10965-012-9840-6

Bai Y, Xiong C, Wei F et al (2015) Gelation study on a hydrophobically associating polymer/polyethylenimine gel system for water shut-off treatment. Energy Fuels 29:447–458. https://doi.org/10.1021/ef502505k

Kudaibergenov S, Nuraje N, Adilov Z et al (2015) Plugging behavior of gellan in porous saline media. J Appl Polym Sci 132:1. https://doi.org/10.1002/app.41256

Acknowledgements

The authors gratefully acknowledge the financial support by Ministry of Education, Malaysia under Exploratory Research Scheme Grant (203/PJKIMIA/6730117) and the School of Chemical Engineering, Universiti Sains Malaysia. Also, special thanks go to the Center for Integrative Petroleum Research, King Fahd University of Petroleum and Minerals, Saudi Arabia for providing necessary assistance to conduct this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Adewunmi, A.A., Ismail, S. & Sultan, A.S. Crosslinked Polyacrylamide Composite Hydrogels Impregnated with Fly Ash: Synthesis, Characterization and Their Application as Fractures Sealant for High Water Producing Zones in Oil and Gas Wells. J Polym Environ 26, 3294–3306 (2018). https://doi.org/10.1007/s10924-018-1204-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-018-1204-9