Abstract

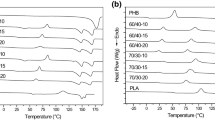

In this paper, poly(lactic acid) (PLA) was toughened and softened by four different molecular size plasticizers namely; glycerol, tributyrin, trilaurin and tristearin. Among four plasticizers studied, tributyrin seems the most appropriate plasticizer for PLA due to its proper molecular size. It increased the tensile elongation at break and impact strength by around ten and three times respectively, with only 10 wt% addition. For PLA with trilaurin and tristearin, they did not show the remarkable toughness improvement. Scanning electron microscope (SEM) observation indicated some phase separations of PLA plasticized with glycerol, trilaurin and tristearin, while tributyrin showed its homogeneity to PLA matrix with higher plastic deformations. Under dynamic load, some shifts of the E′ drop and tanδ peak around 10–40 °C were observed, when glycerol and tributyrin was added. Differential scanning calorimeter (DSC) measurements showed some significant shifts of the transition temperatures, while the degree of crystallinity increased slightly. Heat distortion temperature of the blends fluctuated in a small range of 2–3 °C, which still restricted the use of PLA products above 60 °C.

Similar content being viewed by others

References

Petchwattana N, Naknaen P (2016) J Eng Sci Technol 11(10):1437–1449

Ali F, Chang YW, Kang SC, Yoon JY (2009) Polym Bull 62(1):91–98

Petchwattana N, Covavisaruch S, Petthai S (2014) Polym Bull 71(8):1947–1959

Qian S, Mao H, Zarei E, Sheng K (2015) J Polym Environ 23(3):341–347

Ljungberg N, Wesslen B (2005) Biomacromolecules 6(3):1789–1796

Jaratrotkamjorn R, Khaokong C, Tanrattanakul V (2012) J Appl Polym Sci 124(6):5027–5036

Nijenhuis AJ, Grijpma DW, Pennings AJ (1996) Polymer 37(13):2783–2791

Simon CG Jr, Eidelman N, Kennedy SB, Sehgala A, Khatria CA, Washburn NR (2005) Biomaterials 26(34):6906–6915

Xu YQ, Qu JP (2009) J Appl Polym Sci 112(6):3185–3191

Ren Z, Dong L, Yang Y (2006) J Appl Polym Sci 101(3):1583–1590

Lemmouchi Y, Murariu M, Santos AMD, Amass AJ, Schacht E, Dubois P (2009) Eur Polym J 45(10):2839–2848

Ljungberg N, Colombini D, Wesslen B (2005) J Appl Polym Sci 96(4):992–1002

Marcilla A, Garcia S, Garcia-Quesada JC (2004) J Anal Appl Pyrol 71(2):457–463

Shin SM, Jeon HS, Kim Y, Yoshioka T, Okuwaki A (2002) Polym Degrad Stab 78(3):511–517

Pereira C, Mapuskar K, Rao CV (2007) Environ Toxicol Pharmacol 23(3):319–327

Pakalin S, Aschberger K, Cosgrove O, Lund B, Paya-Perez A, Vegro S (2008) Eur Union Risk Assess Rep 80(1):3–8

Ljungberg N, Andersson T, Wesslén B (2003) J Appl Polym Sci 88(14):3239–3247

Yang SL, Wu ZH, Meng B, Yang W (2009) J Polym Sci Polym Phys 47(2):1136–1145

Wang R, Wan C, Wang S, Zhang Y (2009) Polym Eng Sci 49(12):2414–2420

Martino VP, Jimenez A, Ruseckaite RA (2009) J Appl Polym Sci 112(4):2010–2018

Labrecque LV, Kumar RA, Dave V, Gross RA, Mccarthy SP (1997) J Appl Polym Sci 66(8):1507–1513

Chen BK, Wu TY, Chang YM, Chen AF (2013) Chem Eng J 215–216:886–893

Pandey JK, Singh RP (2005) Starch/Stärke 57(1):8–15

Anker M, Stading M, Hermansson AM (2001) J Agric Food Chem 49(2):989–995

Jacobsen S, Fritz HG (1999) Polym Eng Sci 39(7):1303–1310

Ge H, Yang F, Hao Y, Wu G, Zhang H, Dong L (2013) J Appl Polym Sci 127(4):2832–2839

Kulinski Z, Piorkowska E (2005) Polymer 46(23):10290–10300

Honary S, Orafai H (2002) Drug Dev Ind Pharm 28(6):711–715

Yeh JT, Huang CY, Chai WL, Chen KN (2009) J Appl Polym Sci 112(5):2757–2763

Acknowledgements

The authors would like to acknowledge the research grant supported by National Research Council of Thailand (contrac no. 2555/16).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Petchwattana, N., Sanetuntikul, J. & Narupai, B. Plasticization of Biodegradable Poly(Lactic Acid) by Different Triglyceride Molecular Sizes: A Comparative Study with Glycerol. J Polym Environ 26, 1160–1168 (2018). https://doi.org/10.1007/s10924-017-1012-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-1012-7