Abstract

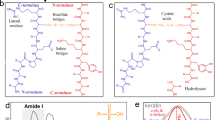

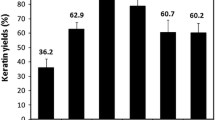

Oleic acid was used to modify keratin extracted from chicken feathers by free radical initiated graft copolymerization. Thereafter, the modified keratin was used for the synthesis of cryogels. The influence of oleic acid modification, the crosslinker content, and the protein concentration on the properties of the cryogels were investigated by Fourier transform infrared spectroscopy, scanning electron microscopy, SDS-PAGE, and through oil holding capacity tests. To enhance the sorption properties, the cryogels were crosslinked with glutaraldehyde. Varying protein concentration from 1.27 to 5.09 wt% and glutaraldehyde concentration from 0 to 5 wt% produced cryogels with oil holding capacity ranging from 4.56 to 10.76 g/g. The highest results exceeded the sorption capacity of previously published oleic acid modified woodchips (6.3 g/g) as well as polypropylene (6 g/g), which is the standard material used in industry.

Similar content being viewed by others

References

Adebajo MO, Frost RL, Kloprogge JT, Carmody O, Kokot S (2003) Porous materials for oil spill cleanup: a review of synthesis and absorbing properties. J Porous Mater 10(3):159–170

Radetić MM, Jocić DM, Jovančić PM, Petrović ZL, Thomas HF (2003) Recycled wool-based nonwoven material as an oil sorbent. Environmental Science Technology 37(5):1008–1012

Teas C, Kalligeros S, Zanikos F, Stournas S, Lois E, Anastopoulos G (2001) Investigation of the effectiveness of absorbent materials in oil spills clean up. Desalination 140(3):259–264

McGovern V (2000) Recycling poultry feathers: more bang for the cluck. Environ Health Perspect 108(8):366–369

Ullah A, Wu J (2013) Feather fiber-based thermoplastics: effects of different plasticizers on material properties. Macromol Mater Eng 298(2):153–162

Reddy N, Chen L, Yang Y. (2013) Biothermoplastics from hydrolyzed and citric acid crosslinked chicken feathers. Mater Sci Eng C 33(3):1203–1208

Aluigi A, Varesano A, Montarsolo A, Vineis C, Ferrero F, Mazzuchetti G (2007) Electrospinning of keratin/poly(ethylene oxide) blend nanofibers. J Appl Polym Sci 104(2):863–870

Senoz E, Stanzione JF, Reno KH, Wool RP, Miller M.E.N. (2012) Pyrolyzed chicken feather fibers for biobased composite reinforcement. J Appl Polym Sci 128(2):983–989

Hu X, Cebe P, Weiss AS, Omenetto F, Kaplan DL. (2012) Protein-based composite materials. Mater Today 15(5):208–215

García-Sabido D, López-Mesas M, Carrillo-Navarrete F. (2016) Chicken feather fibres waste as a low-cost biosorbent of Acid Blue 80 dye. Desalin Water Treat 57(8):1–9

Ghosh A, Collie SR. (2014) Keratinous materials as novel absorbent systems for toxic pollutants. Def Sci J 64(3):209

Zhou L-T, Yang G, Yang X-X, Cao Z-J, Zhou M-H (2014) Preparation of regenerated keratin sponge from waste feathers by a simple method and its potential use for oil adsorption. Environ Sci Pollut Res 21(8):5730–5736

Ifelebuegu AO, Anh Nguyen TV, Ukotije-Ikwut P, Momoh Z (2015) Liquid-phase sorption characteristics of human hair as a natural oil spill sorbent. J Environ Chem Eng 3(2):938–943

Nduka JK, Ezenweke LO, Ezenwa ET (2008) Comparison of the mopping ability of chemically modified and unmodified biological wastes on crude oil and its lower fractions. Bioresour Technol 99(16):7902–7905

Banerjee SS, Joshi MV, Jayaram RV (2006) Treatment of oil spill by sorption technique using fatty acid grafted sawdust. Chemosphere 64(6):1026–1031

Sathasivam K, Mas Haris M (2010) Adsorption kinetics and capacity of fatty acid-modified banana trunk fibers for oil in water. Water Air Soil Pollut 213(14):413–423

Lowden G (1997) Identifying the factors that heighten public concern over oil spills. In: Proceedings of international oil spill conference 1997(1):747–751

Poole A, Lyons R, Church J (2011) Dissolving feather keratin using sodium sulfide for bio-polymer applications. J Polym Environ 19(4):995–1004

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227(5259):680–685

Arai KM, Takahashi R, Yokote Y, Akahane K (1983) Amino-acid sequence of feather keratin from fowl. Eur J Biochem 132(3):501–507

Markley KS (1947) Fatty acids. Their chemistry and physical properties. Interscience, New York

Lodha P, Netravali AN (2005) Thermal and mechanical properties of environment-friendly ‘green’ plastics from stearic acid modified-soy protein isolate. Ind Crops Prod 21(1):49–64

Schrooyen PMM, Dijkstra PJ, Oberthur RC, Bantjes A, Feijen J (2000) Partially carboxymethylated feather keratins. 1. Properties in aqueous systems. J Agric Food Chem 48(9):4326–4334

Yamauchi K, Yamauchi A, Kusunoki T, Kohda A, Konishi Y (1996) Preparation of stable aqueous solution of keratins, and physiochemical and biodegradational properties of films. J Biomed Mater Res 31(4):439–444

Woodin AM (1956) Structure and composition of soluble feather keratin. Biochem J 63(4):576–581

Hamasaki S, Tachibana A, Tada D, Yamauchi K, Tanabe T. (2008) Fabrication of highly porous keratin sponges by freeze-drying in the presence of calcium alginate beads. Mater Sci Eng C 28(8):1250–1254

Tachibana A, Furuta Y, Takeshima H, Tanabe T, Yamauchi K (2002) Fabrication of wool keratin sponge scaffolds for long-term cell cultivation. J Biotechnol 93(2):165–170

Migneault I, Dartiguenave C, Bertrand MJ, Waldron KC (2004) Glutaraldehyde: behavior in aqueous solution, reaction with proteins, and application to enzyme crosslinking. Biotechniques 37(5):790–806

Leung H-W (2001) Ecotoxicology of Glutaraldehyde: Review of environmental fate and effects studies. Ecotoxicol Environ Saf 49(1):26–39

Whang K, Goldstick TK, Healy KE (2000) A biodegradable polymer scaffold for delivery of osteotropic factors. Biomaterials 21(24):2545–2551

Acknowledgements

This research was funded by the Fonds de Recherche du Québec – Nature et Technologies (FRQNT). We gratefully acknowledge the use of laboratory equipment of Prof. Valérie Orsat and Prof. G.S. Vijaya Raghavan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wattie, B., Dumont, MJ. & Lefsrud, M. Synthesis and Properties Modified Feather Keratin-Based Motor Oil Sorbing Cryogels with High Oil Holding Capacity. J Polym Environ 26, 59–65 (2018). https://doi.org/10.1007/s10924-016-0919-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0919-8