Abstract

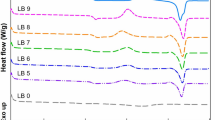

Poly-l-lactide (PLLA) is a widely used sustainable and biodegradable alternative to replace synthetic plastic materials in the packaging industry. Unfortunately, its processing properties are not always optimal, e.g. insufficient melt strength at higher temperatures needed in extrusion coating processes is recognized. In the present work, one have addressed the problem by peroxide modification of commercial PLLA in order to obtain chain branching. Reactive extrusion of PLLA has been carried out in the presence of 0.1, 0.3 and 0.5 wt% of various peroxides [tert-butyl-peroxybenzoate, 2,5-dimethyl-2,5-(tert-butylperoxy)-hexane (Lupersol 101) and benzoyl peroxide]. The peroxides were chosen due to their different decomposition rates at a reactive extrusion temperature of 190 °C. Changes in thermal properties (differential scanning calorimeter) and dynamic rheology, where studied. The rheological analyses were conducted at 240 °C as to mimic typical PLLA extrusion coating conditions. The peroxide-treated PLLAs showed increased complex viscosity and storage modulus at lower frequencies indicating the formation of branched/cross linked architectures. The branching is also supported by the size exclusion chromatography-chromatogram signals revealing the development of higher molecular weight species. The material property changes were dependent on the peroxide and the used peroxide concentration. Gel fraction analysis showed that the peroxides afforded different gel contents and especially 0.5 wt% peroxide produces both an extremely high molar mass and a cross linked structure, not perhaps well suited e.g., for further use in a blending step. The thermal behavior was somewhat unexpected as the materials prepared with 0.5 wt% peroxide showed the highest ability for crystallization and cold crystallization despite substantial cross linking.

Similar content being viewed by others

References

Rhim J, Ng PKW (2007) Crit Rev Food Sci Nutr 47:411–433

Hartmann M, Whiteman N (2000) In polylactide, a new thermoplastic for extrusion coating, vol 1. TAPPI Press, Atlanta, pp 467–474

Lahtinen K, Maydannik P, Johansson P, Kääriäinen T, Cameron DC, Kuusipalo J (2011) Surf Coat Technol 205:3916–3922

Ryan CM, Hartmann MH (1997) In Branching of poly(lactic acid) to increase melt strength for extrusion coating, vol 1. TAPPI Press, Atlanta, pp 139–144

Kang GB, Kim MH, Son Y, Park OO (2009) J Appl Polym Sci 111:3121–3127

Toft N, Rigdahl M (2002) Int Polym Process 17:244–253

Lachtermacher MG, Rudin A (1995) J Appl Polym Sci 58:2077–2094

Ouchi T, Ichimura S, Ohya Y (2006) Polymer 47:429–434

Korhonen H, Helminen A, Seppälä JV (2001) Polymer 42:7541–7549

Liu J, Lou L, Yu W, Liao R, Li R, Zhou C (2010) Polymer 51:5186–5197

Soedergaard A, Niemi M, Selin J, Naesman JH (1995) Ind Eng Chem Res 34:1203–1207

Carlson D, Dubois P, Nie L, Narayan R (1998) Polym Eng Sci 38:311–321

Takamura M, Nakamura T, Takahashi T, Koyama K (2008) Polym Degrad Stab 93:1909–1916

Dean KM, Petinakis E, Meure S, Yu L, Chryss A (2012) J Polym Environ 20:741–747

Sungsanit K, Kao N, Bhattacharya S, Pivsaart S (2010) Korea Aust Rheol J 22:187–195

Dorgan JR, Lehermeier H, Mang M (2000) J Polym Environ 8:1

Liu J, Yu W, Zhou C (2011) J Rheol 55:545–570

Takamura M, Nakamura T, Kawaguchi S, Takahashi T, Koyama K (2010) Polym J 42:600–608

Soedergard A, Naesman JH (1994) Polym Degrad Stab 46:25–30

Takamura M, Sugimoto M, Kawaguchi S, Takahash T, Koyama K (2012) J Appl Polym Sci 123:1468–1478

Ramos VD, da Costa HM, Pereira AO, Rocha MCG, de S. Gomes A (2004) Polym Test 23:949–955

Zulli F, Andreozzi L, Passaglia E, Augier S, Giordano M (2013) J Appl Polym Sci 127:1423–1432

Wu D, Wu L, Zhang M, Zhao Y (2008) Polym Degrad Stab 93:1577–1584

Schulze D, Roths T, Friedrich C (2005) Rheol Acta 44:485–494

Acknowledgments

The authors wish to thank the Finnish Funding Agency for Technology and Innovation (TEKES) for financial support. We also wish to extend our sincere appreciation to Stora Enso Oyj.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khajeheian, M.B., Rosling, A. Rheological and Thermal Properties of Peroxide-Modified Poly(l-lactide)s for Blending Purposes. J Polym Environ 23, 62–71 (2015). https://doi.org/10.1007/s10924-014-0693-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-014-0693-4