Abstract

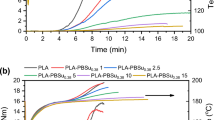

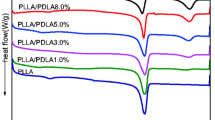

Solid state polymerizations (SSP) and the kinetic behavior in melt state of l-lactide polymerizations employing magnesium stearate as catalyst were investigated. The solid state polymerizations were carried out in two steps where pre-polymers were first prepared in melt polymerizations at 180 °C and the subsequent post-polymerizations were performed around the Tc of polylactide (PLA). In order to find the initial SSP conditions, kinetic profiles of melt polymerizations of l-lactide with magnesium stearate were determined. According to the kinetics data the melt polymerizations were found to be first order with respect to lactide as evident from a linear relationship of logarithmic variations of l-lactide concentration versus time using catalyst/monomer ratios of 1:500 and 1:5,000. When the catalyst content is increased to 1:100 the relationship loses its linearity due to fast propagation in the early stages of the reaction. From the GPC data it can be noted that the molecular weight of PLA can be increased by 5–17 times under the conditions established for our SSP experiments. A comparison between the two step solid state polymerizations and already reported melt polymerizations using the same catalyst showed that SSP furnished polymers with much lower amount of polymer degradation.

Similar content being viewed by others

References

Gironi F, Piemonte G (2011) Environ Prog Sustain Energy 30(3):459–468

Patel M, Bastioli C, Marini L, Würdinger E (2005) Biopolymers Online ed. Wiley-VCH Verlag GmbH & Co

Laine P, Kontio R, Lindqvist C, Suuronen R (2004) Int J Oral Maxillofac Surg 33:240–244

Liang LS, Wong W, Burt HM (2005) J Pharm Sci 94:1204–1215

Schmidmaier G, Wildemann B, Stemberger A, Haas NP, Raschke M (2001) J Biomed Mater Res 58:449–455

Yu Y, Storti G, Morbidelli M (2011) Ind Eng Chem Res 50:7927–7940

Kricheldorf HR, Hachmann-Thiessen H, Schwarz G (2004) Biomacromolecules 5:492–496

Dechy-Cabaret O, Martin-Vaca B, Bourissou D (2004) Chem Rev 104(12):6147–6176

Wheaton CA, Hayes PG, Ireland BJ (2009) Dalton Trans 25:4832–4846

Dobrzynski P, Kasperczyk J, Janeczek H, Bero M (2002) Polymer 43:2595–2601

Dias ML, Palermo LC, Silvino AC (2011) Macromol Symp 299–300:156–163

Kricheldorf HR, Serra A (1985) Polym Bull 14:497–502

FDA’s SCOGS Database (1979) Report No. 60; ID Code: 557-04-0

Sworbrick J, Boylan JC (1995) Encyclopedia of pharmaceutical technology, vol 12. Marcel Dekker, New York, pp 81–103

Katiyar V, Shaama MS, Nanavati H (2011) J Appl Polym Sci 122:2966–2980

Hermans PH, Weidinger A (1961) Macromol Chem 44:24–36

Savitzky A, Golay MJE (1964) Anal Chem 36(8):1627–1639

Wojdyr MJ (2010) Appl Cryst 43:1126

Shyamroy S, Garnaik B, Sivaran S (2005) J Polym Sci Polym Chem 43:2164

Chrisholm MH, Eilerts NW, Huffman JC, Iyer SS, Pacold M, Phomphrai K (2000) J Am Chem Soc 122:11845

Stridsberg KM, Ryner M, Albertsson A-C (2002) Adv Polym Sci 157:42–65

Zhong Z, Schneiderbauer S, Dijkstra PJ, Westerhausen M, Feijen J (2002) J Polym Environ 9:31–38

Nijenhuis AJ, Grijpma DW, Pennings AJ (1992) Macromolecules 25:6414

Katiyar V, Nanavati H (2011) Polym Eng Sci 51(10):2078–2084

Shinno K, Miyamoto M, Kimura Y (1997) Macromolecules 30:6438–6444

Auras R, Lim L-T, Selke SEM, Tsuji H (2010) Poly(lactic acid): synthesis, structures, properties, processing, and applications. Wiley, New Jersey

Degée P, Dubois P, Jérôme R (1997) Macromol Chem Phys 198:1985–1995

Fan Y, Nishida H, Shirai Y, Endo T (2003) Polym Degrad Stab 80:503–511

Noda M, Okuyama H (1999) Chem Pharm Bull 47:467–471

Södergards A, Näsman JH (1996) Ind Eng Chem Res 35:732–735

Kowalski A, Duda A, Penczek S (2000) Macromolecules 33:7359–7370

Acknowledgments

The authors are grateful to the financial support of Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silvino, A.C., de Abreu Talina Martins, D.B., da Costa Rodrigues, A. et al. Kinetic Behavior in Melt State and Solid State Polymerization of Lactide Using Magnesium Stearate as Catalyst. J Polym Environ 21, 1002–1008 (2013). https://doi.org/10.1007/s10924-013-0603-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-013-0603-1