Abstract

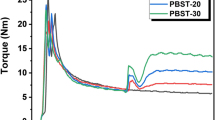

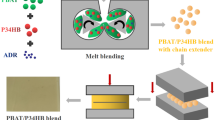

Poly (lactic acid) (PLA) and poly (butylene adipate-co-terephthalate) (PBAT) are biodegradable polyesters and can be blended by twin-screw extrusion. Epoxy-functional styrene acrylic copolymer (ESA) was used as reactive agent for PLA/PBAT blends and the mechanical properties, phase morphology, thermal properties, melt properties, and melt rheological behaviors of the blends were investigated. During thermal extrusion, ESA was mainly a chain extender for the PLA matrix but had no evident reaction with PBAT. The great improvement in the toughness of PLA based blends was achieved by the addition of PBAT of no less than 15 wt% and that of ESA of no more than 0.5 wt%. Although SEM micrographs and the reduced deviation of the terminal slope of G′ and G″ indicated better compatibility and adhesion between the two phases, the blend with ESA was still a two-phase system as indicated in DSC curves. Rheological results reveal that the addition of ESA increased the storage modulus (G′), loss modulus (G″) and complex viscosity of the blend at nearly all frequencies. The melt strength and melt elasticity of the blend are improved by addition of ESA.

Similar content being viewed by others

References

Zhang NW, Wang QF, Ren J et al (2007) China Plast Indus 35:62

Van de Velde K, Kiekens P (2002) Polym Testing 21:433

Lunt J (1998) Polym Degrad Stab 59:145

Drumright RE, Gruber PR, Henton DE (2000) Adv Mater 12:1841

Ren J, Zhang NW (2004) Mater Rev 18:61

Siracusa V, Rocculi P, Romani S et al (2008) Food Sci Technol 19:634

Sedlarik V, Saha N, Sedlarikova J et al (2008) Macromol Symp 272:100

Auras R, Harte B, Selke S (2004) Macromol Biosci 4:835

Witt U, Einig T, Yamamoto M et al (2001) Chemosphere 44:289

Gan ZH, Kuwabara K, Yamamoto M et al (2006) J Polym Sci, Part B: Polym Phys 44:3006

Jun CL (2000) J Polym Environ 8:33

Guan J, Fang Q, Hanna MA (2004) J Polym Environ 12:57

Zhang JW, Jiang L, Zhu LY (2006) Biomacromolecules 7:1551

Jiang L, Wolcott MP, Zhang J (2006) Biomacromolecules 7:199

Jiang L, Liu B, Zhang JW (2009) Ind Eng Chem Res 48:7594

Teamsinsungvon A, Ruksakulpiwat Y, Jarukumjorn K (2010) Adv Mater Res 123–125:193

Bhatia A, Gupta RK, Bhattacharya SN, Choi HJ (2007) Kor Aust Rheol J 19:125

Ma XF, Yu JG, Wang N (2006) J Polym Sci, Part B: Polym Phys 44:94

Harada M, Ohya T, Iida K (2007) J Appl Polym Sci 106:1813

John J, Bhattacharya M (2000) Polym Int 49:860

Wang L, Ma W, Gross RA, McCarthy SP (1998) Polym Degrad Stab 59:161

John J, Bhattacharya M (2000) Polym Int 49:860

Signori F, Coltelli MB, Bronco S (2009) Polym Degrad Stab 94:74

Babanalbandi A, Hill DJT, Hunter DS, Kettle L (1999) Polym Int 48:980

Zhang NW, Wang QF, Ren J et al (2009) J Mater Sci 44:250

Semba T, Kitagawa K, Ishiaku US et al (2006) J Appl Polym Sci 101:1816

Ho K, Kale L, Montgomery S (2002) J Appl Polym Sci 85:1408

Ahmed J, Zhang JX, Song Z, Varshney SK (2009) J Therm Anal Calorim 95:957

Gu SY, Zhang K, Ren J et al (2008) Carbohydr Polym 74:79

Sinha Ray S, Okamoto M (2003) Macromol Mater Eng 288:936

Sinha Ray S, Yamada K, Okamoto M, Ueda K (2003) Polymer 44:857

Hyun YH, Lim ST, Choi HJ et al (2001) Macromolecules 34:8084

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, N., Zeng, C., Wang, L. et al. Preparation and Properties of Biodegradable Poly(lactic acid)/Poly(butylene adipate-co-terephthalate) Blend with Epoxy-Functional Styrene Acrylic Copolymer as Reactive Agent. J Polym Environ 21, 286–292 (2013). https://doi.org/10.1007/s10924-012-0448-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-012-0448-z