Abstract

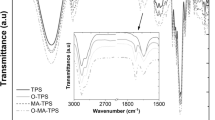

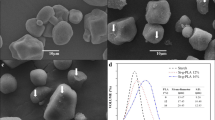

Modified thermoplastic high amylose starch (MTPS) was synthesized by reactive extrusion in the presence of maleic anhydride (MA) as an esterification agent in a twin-screw extruder. The objective of this work was the preparation of reactive thermoplastic starch in the presence of glycerol and with different amounts of maleic anhydride (MA) and free-radical initiator, in order to improve processability and reactivity. The concentration of MA added varied from 2 to 6 wt% (of starch + glycerol), and the free-radical initiator, 2,5-bis(tert-butylperoxy)-2,5-dimethylhexane, also called Luperox 101, varied from 0.1 to 0.5 wt% (of starch + glycerol). Characterization of maleated thermoplastic starch was performed using dynamic light scattering and thermal analysis. Further, proof of chemically modified extrudate was determined by Fourier transform infrared spectroscopy and by soxhlet extraction with acetone. The modified high amylose corn starch (20 or 30% glycerol) could be pelletized and gave pellets that were more transparent than thermoplastic starches not modified with maleic anhydride. There was negligible change in hydrodynamic radius as the percentage of maleic anhydride increased. However, as the percentage of Luperox 101 increased, the hydrodynamic radius decreased. It could be inferred that the molecular weight decreased as the percentage of free-radical initiator increased. Using the maximum temperature in the extrusion process of 165 °C instead of 135 °C caused a decrease in the hydrodynamic radius, due to the high influence of the temperature profile on the molecular weight of the thermoplastic starch. The MTPS samples presented higher melting temperatures compared to TPS samples. The soxhlet studies indicated that the plasticizer, glycerol, was chemically linked to the starch. Using the maximum temperature of 165 °C versus 135 °C in the extrusion temperature profile resulted in more interaction between glycerol and starch.

Similar content being viewed by others

References

Khare A, Deshmukh S (2006) J Plast Film Sheeting 22:193

Thuwall M, Boldizar A, Rigdahl M (2006) Carbohydr Polym 65:441

George ER, Sullivan TM, Park EH (1994) Polym Eng Sci 34:17

Dias Alves V, Mali S, Beleia A, Grossmann MVE (2007) J Food Eng 78:941

Kalambur S, Rizvi SSH (2006) J Plast Film Sheeting 22:39

Hung PV, Maeda T, Morita N (2006) Trends Food Sci Technol 17:448

Vilpoux O, Avérous L (2003) Plásticos a base de amido. In: Cereda MP, Vilpoux O (eds) Tecnologia, usos e potencialidades de tuberosasamiláceas Latino Americanas, Collection Culturas de Tuberosas Latinoamericanas, vol 3, chap 18. São Paulo, Fundação Cargill, pp 499–529

Lourdin D, Della Valle G, Colonna P, Poussin D (1999) Revue Generale des Caoutchoucs Plastiques 780:39

Narayan R (1998) Commercialization technology: a case study of starch based biodegradable plastics. In: Sessa DJ, Willett JL (eds) Paradigm for successful utilization of renewable resources. AOCS Press, Champaign, p 78

Krishnan M (1996) Biodegradable multi-component polymeric materials based on unmodified starch-like polysaccharides. US Patent 5,500,465, 19 Mar 1996

Narayan R (2006) Chemically modified plasticized starch compositions by extrusion processing. US Patent 7,153,354, 26 Dec 2006

Nabar Y (2004) Design and engineering of novel starch-based foam and film products. Ph.D. Dissertation, Michigan State University, East Lansing, Michigan

Raquez J-M, Nabar Y, Srinivasan M, Shin B-Y, Narayan R, Dubois P (2008) Carbohydr Polym 74:159

Carlson D, Dubois P, Nie L, Narayan R (1998) Polym Eng Sci 38:311

Nabar Y, Raquez JM, Dubois P, Narayan R (2005) Biomacromolecules 6:807

Roger P, Tran V, Lesec J, Colonna P (1996) J Cereal Sci 24:247

Acknowledgments

One of the authors wishes to thank the financial support provided by CAPES and CNPq.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stagner, J., Dias Alves, V., Narayan, R. et al. Thermoplasticization of High Amylose Starch by Chemical Modification Using Reactive Extrusion. J Polym Environ 19, 589–597 (2011). https://doi.org/10.1007/s10924-011-0307-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-011-0307-3