Abstract

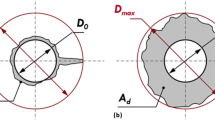

The present work estimated the accuracy of non-destructive tests in quantifying the delaminated area in CFRP samples submitted to a 4-point end notched flexure test, to evaluate the relevance of measuring the delamination area to calculate fracture toughness in mode II, instead of of the traditional method which evaluates the delamination length visually through the sample lateral faces. In this way, IR thermography, eddy current, ultrasonic microscopy, and X-ray computed microtomography (as reference) tests were employed. A methodological sequence based on image processing algorithms was performed to calculate the values of the delaminated areas for all NDT techniques. The first two techniques did not provide a clear separation between the defective and intact zones and are strongly influenced by edge effects. The result is different for the two last tests, which demonstrated a satisfactory definition of the delamination limit region. The ultrasonic microscopy test revealed results similar to microtomography, proving to be a promising alternative for this type of measurement. In addition, the importance of using more accurate methods in calculating the crack length is emphasized, as the traditional visual measurement can be highly susceptible to errors and does not allow evaluating potential tunneling effects or an uneven delamination front.

Similar content being viewed by others

References

Mathes, V.: The composites industry: plenty of opportunities in heterogeneous market. Reinf. Plast. 62(1), 44–51 (2018)

Greenhalgh, E.S.: Failure Analysis and Fractography of Polymer Composites. Woodhead Publishing, Cambridge (2009)

Tanaka, K., Kageyama, K., Hojo, M.: Prestandardization study on mode II interlaminar fracture toughness test for CFRP in Japan. Composites 26, 257–267 (1995)

Silversides, I., Maslouhi, A., Laplante, G.: Interlaminar fracture characterization in composite materials by using acoustic emission. In: 5th International Symposium on NDT in Aerospace. Singapore (2013)

Campilho, R.D., et al.: Interlaminar Fracture Characterization of a Carbon-Epoxy Composite in Pure Mode II. Mater. Sci. Forum 636–637, 1518–1524 (2010)

Martin, R.H., Davidson, B.D.: Mode II fracture toughness evaluation using four point bend, end notched flexure test. Plast. Rubber Compos. 28(8), 401–406 (1999)

Blackman, B.R.K., Pavan, A., Williams, J.G.: Fracture of Polymers, Composites and Adhesives II. Elsevier, Boston (2003)

Schuecker, C., Davidson, B.D.: Evaluation of the accuracy of the four-point bend end-notched exure test for mode II delamination toughness determination. Compos. Sci. Technol. 60, 2137–2146 (2000)

Wang, W.E., et al.: Experimental investigation on test methods for mode II interlaminar fracture testing of carbon fiber reinforced composites. Compos A 40, 1447–1455 (2009)

Murray, B.R., et al.: Crack tip monitoring of mode I and mode II delamination in CF/epoxies under static and dynamic loading conditions using digital image correlation. Proceedings 2, 389 (2018)

Carlsson, L.A., Adams, D.F., Pipes, R.B.: Experimental Characterization of Advanced Composite Materials. CRC Press, Boca Raton (2014)

Vinciquerra, A.J., Davidson, B.D.: Effect of crack length measurement technique and data reduction procedures on the perceived toughness from four-point bend end-notched flexure tests. J. Reinf. Plast. Compos. 23, 1051 (2004)

Tsao, C.C., Hocheng, H.: Computerized tomography and C-scan for measuring delamination. Int. J. Mach. Tools Manuf. 45, 1282–1287 (2005)

Li, P., et al.: Defect monitoring of CFRP with ultrasonic C-scan method. Adv. Mater. Res. 243–249, 5343–5348 (2011)

Schadow, F., et al.: Ultrasonic inspection and data analysis of glass- and carbon-fibre-reinforced plastics. Procedia Struct Integr 7, 299–306 (2017)

Ehrlich, I., Dinnebier, H., Jost, C.: Comparison of impact delaminations in CFRP using different test methods. J. Achiev. Mater. Manuf. Eng. 73(2), 128–138 (2015)

Kersemans, M., et al.: Non-destructive testing of composites by ultrasound, local defect resonance and thermography. Proceedings 2, 554 (2018)

Hasiotis, T., Badogiannis, E., Tsouvalis, N.G.: Application of ultrasonic C-scan techniques for tracing defects in laminated composite materials. J. Mech. Eng. 57(3), 192–203 (2011)

Sket, F., et al.: In situ tomographic investigation of damage development in ±45° carbon fibre reinforced laminates. Mater. Sci. Technol. 31, 587–593 (2015)

Suvarna, R., et al.: Effect of temperature on low velocity impact damage and post-impact flexural strength of CFRP assessed using ultrasonic C-scan and micro-focus computed tomography. Compos. B 66, 58–64 (2014)

Vavilov, V.P.: Modeling and characterizing impact damage in carbon fiber composites by thermal/infrared non-destructive testing. Compos. B 61, 1–10 (2014)

Maierhofer, C., et al.: Characterizing damage in CFRP structures using flash thermography in reflection and transmission configurations. Compos. B 57, 35–46 (2014)

Swiderski, W.: Non-destructive testing of carbon fiber reinforced plastic by infrared thermography methods. Int. J. Civ. Environ. Eng. 10, 1470 (2016)

Daccardi, E., et al.: Pulsed phase thermography approach for the characterization of delaminations in CFRP and comparison to phased array ultrasonic testing. J. Nondestruct. Eval. 38, 20 (2019)

Chrysafi, A.P., Athanasopoulos, N., Siakavellas, N.J.: Damage detection on composite materials with active thermography. Int. J. Therm. Sci. 116, 242–253 (2017)

Toscano, C. et al.: Lockin thermography to monitor propagation of delamination in CFRP composites during compression tests. In: 11th International Conference on Quantitative InfraRed Thermography. Naples, Italy (2012)

Goeje, M.P., Wapenaar, K.E.: Non-destructive inspection of carbon fibre-reinforced plastics using eddy current methods. Composites 23(3), 147–157 (1992)

Mizukami, K., et al.: Enhancement of sensitivity to delamination in eddy current testing of carbon fiber composites by varying probe geometry. Compos. Struct. 226, 111227 (2019)

Xu, X., et al.: Detection of delamination in laminated CFRP composites using eddy current testing: simulation and experimental study. Int. J. Appl. Electromagn. Mech. 57(2), 1–16 (2018)

Heuer, H., Schulze, H.M., Meyendor, N.: High Resolution Inspection of Carbon Fiber Materials by Eddy Current Techniques. In: 2nd International Symposium on NDT on Aerospace. Hamburg (2010)

Todoroki, A., Kobayashi, H., Matsuura, K.: Application of the electric potential method to smart CFRP structures for detecting delaminations. JSME Int. J. Ser. A 38(4), 524–530 (1995)

Stinchcomb, W.W.: Nondestructive evaluation of damage accumulation processes in composite laminates. Compos. Sci. Technol. 25, 103–118 (1986)

Vinciquerra, A.J., et al.: Determination of the mode II fatigue delamination toughness of laminated composites. J. Reinf. Plast. Compos. 21, 663 (2002)

Sause, M.G.: Computed tomography. In: In Situ Monitoring of Fiber-Reinforced Composites: Theroy, Basic Concepts, Methods and Applications. Springer International Publishing, p. 457–532 (2016)

Todoroki, A., Kobayashi, H.: Image analysis of delamination cracks in carbon-fibre composites by scanning acoustic microscopy. Compos. Sci. Technol. 52, 551–559 (1994)

Gao, S.L., Kim, J.K.: Scanning acoustic microscopy as a tool for quantitative characterisation of damage in CFRPs. Compos. Sci. Technol. 54, 345–354 (1999)

Petronyuk, Y., et al.: Study of failure mechanisms of CFRP under mechanical load by impulse acoustic microscopy. Polym. Eng. Sci. 57, 703 (2017)

Ogihara, S., Takeda, N., Kobayashi, A.: Characterization and modeling of fatigue damage in quasi-isotropic CFRP laminates with circular holes by scanning acoustic microscopy. Adv. Compos. Mater. 6(1), 65–73 (2012)

Pomarède, P., et al.: Damage evaluation inwoven glass reinforced polyamide 6.6/6 composites using ultrasound phase-shift analysis and x-ray tomography. J. Nondestruct. Eval. 37, 1–21 (2018)

Eckel, S., et al.: Investigation of damage in composites using nondestructive nonlinear acoustic spectroscopy. Exp. Mech. 57, 207–217 (2017)

Carmas Composites: Informe técnico: Wilpox APV CH4L (2016)

Moore, D.R., Pavan, A., Williams, J.G. (eds.): Fracture Mechanics Testing Methods for Polymers, Adhesives and Composites. Elsevier Science Ltd, Amsterdam (2001)

Kotik, H.G.: Fractura y fatiga de materiales compuestos de matriz polimérica empleados en palas de generadores eólicos de alta potencia. Universidad Nacional del Sur, Bahia Blanca, Argentina (2016)

Ho, S., Suo, Z.: Tunneling cracks in constrained layers. J. Appl. Mech. 60(4), 890–894 (1993)

Suiker, A.S.J., Fleck, N.A.: Modelling of fatigue crack tunneling and delamination in layered composites. Compos. A 37, 1722–1733 (2006)

Panda, S.K., Pradhan, B.: Thermoelastic analysis of the asymmetries of interfacial embedded delamination characteristics in laminated FRP composites. Compos. A Appl. Sci. Manuf. 38(2), 337–347 (2007)

Davidson, B.D., Sediles, F.O.: Mixed-mode I-II–III delamination toughness determination via a shear–torsion-bending test. Compos. A Appl. Sci. Manuf. 42(6), 589–603 (2011)

Yu, B., et al.: 2D and 3D imaging of fatigue failure mechanisms of 3D woven composites. Compos. A Appl. Sci. Manuf. 77, 37–49 (2015)

Singh, R.: Eddy current testing. In: SINGH, R. Applied Welding Engineering. Butterworth-Heinemann, Cap. 7 (2012)

Vala, M.H., Baxi, A.: A review on otsu image segmentation. Int. J. Adv. Res. Comput. Eng. Technol. (IJARCET) 2(2), 387–389 (2013)

Ciampa, F., et al.: Recent advances in active infrared thermography fornon-destructive testing of aerospace components. Sensors 18, 609 (2018)

Kalter, L.R.: Characterisation of damage in composite materials using infrared thermography. University of Twente (2019)

Wang, S., Chung, D.D.L.: Electrical behavior of carbon fiber polymer-matrix composites in the through-thickness direction. J. Mater. Sci. 35, 91–100 (2000)

Cheng, J., et al.: Application of low frequency ECT method in noncontact detection and visualization of CFRP material. Compos. B 110, 141–152 (2017)

Acknowledgements

The authors would like to acknowledge Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPQ) and Deutscher Akademischer Austauschdienst (DAAD) for the financial support and enable the academic partnership between Federal University of Rio de Janeiro, Technische Universität Dresden (TU Dresden) and the Fraunhofer-Institut für Keramische Technologien und Systeme (Fraunhofer IKTS Institute). The authors also thank Juan E. Perez Ipiña (Consejo Nacional de Investigaciones Científicas y Técnicas—CONICET) and INVAP SE for supplied the material.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Castro, D.S.V., Matvieieva, N., Grosso, M. et al. Evaluation of Mode II Delamination Area by Non-destructive Techniques: Accuracy and Influence on Fracture Toughness Calculation. J Nondestruct Eval 40, 58 (2021). https://doi.org/10.1007/s10921-021-00789-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-021-00789-3