Abstract

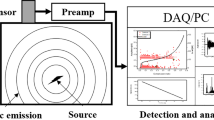

The application of aluminum alloys in various industries such as automotive and aerospace, is inclusive. In addition, in these industries, holes in these materials are used for bolts and rivets. Accordingly, in this article, the initiation and the propagation of cracks in the 2024 aluminum alloy were detected, by means of two methods including acoustic emission and vibration analysis approaches. For this objective, acoustic and vibration sensors were connected to the open-hole aluminum specimen under tensile loading and signals were acquired. Obtained results indicated that the energy of signals, which was recorded by sensors, was comparable to the stress–strain diagram and therefore, the efficiency of two methods in detecting the crack initiation was proved. The calculated maximum stress at the specimen edge by the vibration analysis was closer to experimental data, in comparison to the acoustic emission approach. Then, the fracture frequency of the aluminum alloy was calculated using two mentioned methods and by the fast Fourier transform. By the use of the cumulative energy, which was calculated from recorded signals, the crack propagation was also detected by both approaches and a better efficiency for predicting the fracture by the acoustic emission method was shown. At the end, images of the scanning electron microscopy from the crack and the fracture surface were also demonstrated.

Similar content being viewed by others

References

Mathers, G.: The Welding of Aluminum and its Alloy. Woodhead Publishing, Cambridge (2002)

Khazaee, M., Ahmadi, H., Omid, M., Moosavian, A., Khazaee, M.: Classifier fusion of vibration and acoustic signals for fault diagnosis and classification of planetary gears based on Dempster–Shafer evidence theory. Proc. Inst. Mech. Eng. Part E 228(1), 21–32 (2014)

Grosse, C.U., Masayasu, O.: Acoustic Emission Testing. Springer, New York (2008)

Baydar, N., Ball, A.: A comparative study of acoustic and vibration signals in detection of gear failures using Wigner–Ville distribution. Mech. Syst. Signal Process. 15(6), 1091–1107 (2001)

Saxena, A., Saad, A.: Evolving an artificial neural network classifier for condition monitoring of rotating mechanical systems. Appl. Soft Comput. 7(1), 441–454 (2007)

Rafiee, J., Arvani, F., Harifi, A., Sadeghi, M.H.: Intelligent condition monitoring of a gearbox using artificial neural network. Mech. Syst. Signal Process. 21(4), 1746–1754 (2007)

Cousland, K., Scala, C.M.: Acoustic emission during the plastic deformation of aluminum alloys 2024 and 2124. Mater. Sci. Eng. 57, 23–29 (1983)

Blanchette, Y., Dickson, J.I., Bassim, M.N.: Acoustic emission behavior crack growth of 7075-T651 Al alloy. Eng. Fract. Mech. 24(5), 647–656 (1986)

Yang, D., Wang, J., Li, D., Kuang, K.S.C.: Fatigue crack monitoring using plastic optical fiber sensor. Procedia Struct. Integr. 5, 1168–1175 (2017)

Sayar, H., Alizadeh, M., Azadi, M., Ghasemi-Ghalebahman, A., Jafari, S.M.: Investigation of crack growth behavior in aluminum alloy under low-cycle fatigue loading using a acoustic emission method. In: 26th Annual International Conference of Iranian Society of Mechanical Engineers, Semnan, Iran, April 24–26, 2018

Sayar, H., Alizadeh, M., Azadi, M., Ghasemi-Ghalebahman, A., Jafari, S.M., Mafi, A.: Investigation of crack growth behavior in aluminum alloy used in engine components, by acoustic emission method. J. Engine Res. 48, 3–12 (2017)

Chai, M., Zhang, J., Zhang, Z., Duan, Q., Cheng, G.: Acoustic emission studies for characterization of fatigue crack growth in 316LN stainless steel and welds. Appl. Acoust. 126, 101–113 (2017)

Rivera, F.G., Edwards, G., Eren, E., Soua, S.: Acoustic emission technique to monitor crack growth in a mooring chain. Appl. Acoust. 139, 156–164 (2018)

Hao, Q., Zhang, X., Wang, K., Shen, Y., Wang, Y.: A signal-adapted wavelet design method for acoustic emission signals of rail cracks. Appl. Acoust. 139, 251–258 (2018)

Bruzelius, K., Mba, D.: An initial investigation on the potential applicability of acoustic emission to rail track fault detection. NDT&E Int. 37, 507–516 (2004)

Jomdecha, C., Prateepasen, A., Kaewtrakulpong, P.: Study on source location using an acoustic emission system for various corrosion types. NDT&E Int. 40, 584–593 (2007)

Toutountzakis, T., Tan, C.K., Mba, D.: Application of acoustic emission to seeded gear fault detection. NDT&E Int. 38, 27–36 (2005)

Abdulkarem, W., Amuthakkannan, R., Al-Raheem, K.F.: Centrifugal pump impeller crack detection using vibration analysis. In: 2nd International Conference on Research in Science, Engineering and Technology, Dubai, UAE, March 21–22, 2014

Li, Z., Ma, Z., Liu, Y., Teng, W., Jiang, R.: Crack fault detection for a gearbox using discrete wavelet transform and an adaptive resonance theory neural network. J. Mech. Eng. 61(1), 63–73 (2015)

Moosavian, A., Najafi, G., Ghobadian, B., Mirsalim, M.: The effect of piston scratching fault on the vibration behavior of an IC engine. Appl. Acoust. 126, 91–100 (2017)

Bhalla, S., Soh, C.K.: High frequency piezoelectric signatures for diagnosis of seismic/blast induced structural damages. NDT&E Int. 37, 23–33 (2004)

Loutridis, S., Douka, E., Hadjileontiadis, L.J.: Forced vibration behavior and crack detection of cracked beams using instantaneous frequency. NDT&E Int. 38, 411–419 (2005)

Eftekharnejad, B., Addali, A., Mba, D.: Shaft crack diagnostics in a gearbox. Appl. Acoust. 73, 723–733 (2012)

Barelli, L., Bidini, G., Buratti, C., Mariani, R.: Diagnosis of internal combustion engine through vibration and acoustic pressure non-interasive measurement. Appl. Therm. Eng. 29, 1707–1713 (2009)

Chandroth, G., Sharkey, A., Sharkey, N.: Cylinder pressures and vibration in internal combustion engine condition monitoring. Proc. Comadem 99, 294–297 (1999)

ASTM D5766/D5766M-11: Standard Test Method for Open-hole Strength of Polymer Matrix Composite Laminates. ASTM International, West Conshohocken, PA (2011)

Metals Handbook: Volume 2, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials. ASM International (1990)

Okafor, C., Natarajan, S.: Acoustic emission monitoring of tensile testing of corroded and un-corroded clad aluminum 2024-T3 and characterization of effects of corrosion on AE source events and material tensile properties. AIP Proc. 58, 492–500 (2014)

ASTM E976-10: Standard Guide for Determining the Reproducibility of Acoustic Emission Sensor Response. ASTM International (2010)

Beattie, A.G.: Acoustic emission, principles and instrumentation. J. Acoust. Emiss. 2, 95–128 (1983)

ISO 12716: Nondestructive Testing-Acoustic Emission Inspection: Vocabulary (2001)

Nakamura, H., Ohtsu, M., Enoki, M., Mizutani, Y., Shigeishi, M., Inaba, H., Nakano, M., Shiotani, T., Yuyama, S., Sugimoto, S.: Practical Acoustic Emission Testing. Springer, Berlin (2016)

Sujatha, C.: Vibration and Acoustics Measurement and Signal Analysis. McGraw Hill, London (2010)

Rao, K.R., Kiml, D.N., Hwang, J.J.: Fast Fourier Transform: Algorithms and Applications. Springer, Berlin (2010)

Roberts, T.M., Talebzadeh, M.: Acoustic emission monitoring of fatigue crack propagation. J. Constr. Steel Res. 59, 695–712 (2003)

Bassim, M.N., Lawrence, S.S., Liu, C.D.: Detection of the onset of fatigue crack growth in rail steels using acoustic emission. Eng. Fract. Mech. 47(2), 207–214 (1994)

Harris, D.O., Dunegan, H.L.: Continuous monitoring of fatigue-crack growth by acoustic-emission techniques. Exp. Mech. 14, 71–81 (1974)

Shigley, J.E., Mischkle, C.R.: Standard Hand book of Machine Design. McGraw Hill, London (1986)

Pilkey, W.D.: Peterson’s Stress concentration Factors. Wiley, New York (1997)

Howland, R.C.J.: On the stresses in the neighborhood of a circular hole in a strip under tension. Philos. Trans. R. Soc. Lond. Ser. A 229, 49–86 (1930)

Young, W.C., Budynas, R.G.: Roark’s Formulas for Stress and Strain, 7th edn. McGraw Hill, London (2001)

Ennaceur, C., Laksimi, A., Herve, C., Cherfaoui, M.: Monitoring crack growth in pressure vessel steels by the acoustic emission technique and the method of potential difference. Int. J. Press. Vessels Pip. 83, 197–204 (2006)

Khazaee, M., Ahmadi, H., Omid, M., Banakar, A., Moosavian, A.: Feature-level fusion based on wavelet transform and artificial neural network for fault diagnosis of planetary gearbox using acoustic and vibration signals. Insight Non-Destruct. Test. Cond. Monit. 55(6), 323–330 (2013)

Khazaee, M., Ahmadi, H., Omid, M., Moosavian, A., Khazaee, M.: Classifier fusion of vibration and acoustic signals for fault diagnosis and classification of planetary gears based on dempster-shafer evidence theory. Proc. Inst. Mech. Eng. Part E 228(1), 21–32 (2014)

Chen, J., Yuan, X., Hu, Z., Li, T., Wu, K., Li, C.: Improvement of resistance-spot-welded joints for DP 600 steel and A5052 aluminum alloy with Zn slice interlayer. J. Manuf. Process. 30, 396–405 (2017)

Tocci, M., Pola, A., Montesano, L., Merlin, M., Garagnani, G.L., La Vecchia, G.M.: Tensile behavior and impact toughness of an AlSi3MgCr alloy. Procedia Struct. Integr. 3, 517–525 (2017)

Bobbili, R., Madhu, V., Gogia, A.K.: Tensile behavior of aluminum 7017 alloy at various temperatures and strain rates. J. Mater. Res. Technol. 5(2), 190–197 (2016)

Ma, H., Huang, L., Tian, Y., Li, J.: Effects of strain rate on dynamic mechanical behavior and microstructure evolution of 5A02-O aluminum alloy. Mater. Sci. Eng. A 606, 233–239 (2014)

Acknowledgements

Authors should thank Irankhodro Powertrain Company (IPCo.) for the financial support and providing the equipment for the acoustic emission approach and the vibration analysis. Authors also tend to have a special thanks to Dr. S.M. Jafari and Dr. A. Moosavian, for their guidance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sayar, H., Azadi, M. & Alizadeh, M. Detection of Crack Initiation and Propagation in Aluminum Alloy Under Tensile Loading, Comparing Signals Acquired by Acoustic Emission and Vibration Sensors. J Nondestruct Eval 38, 100 (2019). https://doi.org/10.1007/s10921-019-0639-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-019-0639-9