Abstract

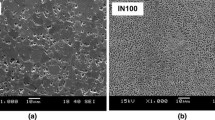

Eddy current (EC) measurements have shown promise toward becoming a nondestructive method of residual stress characterization, particularly for nickel-base superalloys. However, previous studies on shot-peened materials have shown apparent discrepancies between directly measured residual stress profiles and those determined from EC data. Here, we report a study of the inter-relationship among electrical conductivity deviation, residual stress and texture of shot peened materials, in order to improve understanding of the piezoresistivity effect that is essential to the on-going efforts to make EC measurements a viable technique for residual stress assessment. Specifically, we develop a macroscopic piezoresistivity theory for polycrystalline materials influenced by texture. The theory was applied to analyze the swept high frequency eddy current data obtained from a shot peened Inconel 718 sample, which was found to exhibit shot-induced texture in the near surface region using X-ray diffraction (XRD) and orientation imaging microscopy (OIM). The residual stress profile of the peened sample was inverted from EC data using a physics model-based approach, and was found to agree with the residual stress profiles measured independently using the standard layer removal XRD technique.

Similar content being viewed by others

References

John, R., Larsen, J.M., Buchanan, D.J., Ashbaugh, N.E.: Incorporating residual stresses in life prediction of turbine engine disks. In: Proceedings from NATO RTO (AVT) Symposium on Monitoring and Management of Gas Turbine Fleets for Extended Life and Reduced Costs, Manchester, UK, 8–11 Oct., 2001

Lu, J. (ed.): Handbook of Measurement of Residual Stresses. Fairmont, Upper Saddle River (1996)

Cullity, B.D., Stock, S.R.: Elements of X-Ray Diffraction, 3rd edn. Prentice Hall, Upper Saddle River (2001)

Moore, M.G., Evans, W.P.: SAE Trans. 66, 340 (1958)

American Society for Metals: Metals Handbook, vol. 10, pp. 380–392. Metals Park, Ohio (1986)

Schoenig, F.C., Soules, J.A., Chang, H., Dicillo, J.J.: Mater. Eval. 53, 22 (1995)

Blaszkiewicz, M., Albertin, L., Junker, W.: Mater. Sci. Forum 210–213, 179 (1996)

Chang, H., Schoenig, F.C., Soules, J.A.: Mater. Eval. 57, 1257 (1999)

Zilberstein, V., Fisher, M., Grundy, D., Schlicker, D., Tsukernik, V., Vengrinovich, V., Goldfine, N., Yentzer, T.: ASME J. Press. Vessel Technol. 124, 375 (2002)

Blodgett, M.P., Nagy, P.B.: In: Thompson, D.O., Chimenti, D.E. (eds.) Review of Progress in Quantitative Nondestructive Evaluation 23B. AIP Conference Proceedings, vol. 700, pp. 1216–1223. AIP, Melville (2004)

Blodgett, M.P., Nagy, P.B.: J. Nondestr. Eval. 23, 107 (2004)

Yu, F., Blodgett, M.P., Nagy, P.B.: J. Nondestr. Eval. 25, 17 (2006)

Yu, F., Nagy, P.B.: J. Appl. Phys. 95, 8340 (2004)

Yu, F., Nagy, P.B.: J. Appl. Phys. 96, 1257 (2004)

Yu, F., Blodgett, M.P., Nagy, P.B.: J. Nondestr. Eval. 25, 107 (2006)

Nakagawa, N., Lee, C., Shen, Y.: In: Thompson, D.O., Chimenti, D.E. (eds.) Review of Progress in Quantitative Nondestructive Evaluation, vol. 25, pp. 1418–1424. AIP, Melville (2006)

Lee, C., Shen, Y., Lo, C.C.H., Nakagawa, N.: In: Thompson, D.O., Chimenti, D.E. (eds.) Review of Progress in Quantitative Nondestructive Evaluation, vol. 26. AIP, Melville (2007)

Shen, Y., Lee, C., Lo, C.C.H., Nakagawa, N., Frishman, A.M.: J. Appl. Phys. 101, 014907 (2007)

Timoshenko, S.: Theory of Elasticity, 3rd edn. McGraw-Hill, New York (1970)

Roe, R.J.: J. Appl. Phys. 37, 2069 (1966)

Roe, R.J.: J. Appl. Phys. 36, 2024 (1965)

Roe, R.J.: J. Chem. Phys. 40, 2608 (1964)

Nye, J.F.: Physical Properties of Crystals, Their Representation by Tensors and Matrices. Clarendon, Oxford (1957)

Bunge, H.J.: Z. Met.kd. 56, 872 (1965)

Bunge, H.J.: Texture Analysis in Materials Science: Mathematical Methods. Butterworths, London (1982). Translated by P.R. Morris

Thompson, R.B., Smith, J.F., Lee, S.S., Johnson, G.G.: Metall. Trans. A 20A, 2431 (1989)

Thompson, R.B.: Mater. Eval. 51, 1162–1165, 1173 (1993)

Thompson, R.B.: In: Birnbaum, G., Auld, B.A. (eds.) Sensing for Materials Characterization, Processing, and Manufacturing, pp. 23–45. American Society for Nondestructive Testing, Inc., 1998

Cheng, C.C., Dodd, C.V., Deeds, W.E.: Int. J. Nondestr. Test. 3, 109 (1971)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, Y., Lo, C.C.H., Nakagawa, N. et al. Residual Stress Profile Assessment by Eddy Current for Shot Peened Nickel Superalloy. J Nondestruct Eval 29, 1–13 (2010). https://doi.org/10.1007/s10921-009-0060-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10921-009-0060-x