Abstract

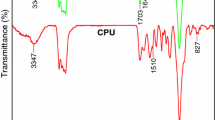

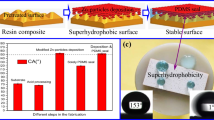

In this study, a low-cost thermosetting unsaturated polyester resin (UPR) reinforced with ceramic wastes was produced and employed as a substrate, which was then coated with a hydrophobic solution comprising nano/micro scale ZnO particles. Ultra-water-repellent composite substrate surfaces were produced by a two-step process. Firstly, the composite surfaces were abraded with 600 SiC paper in order to create rough surface. In order to lower their surface energy and create unique surface topography, the textured composite substrate surfaces were next covered with a single or double layer of hydrophobic solution containing nano/micro ZnO particles. Contact angle measurements, surface free energy calculations, field emission scanning electron microscopy (FESEM), energy-dispersive X-ray spectrum (EDS), and optical profilometer were all used in the surface characterisation process. The highest contact angle was obtained as 157.8° when a double layer of micro ZnO-containing hydrophobic coating was applied. Surfaces coated with nano ZnO particles did not have a self-cleaning effect, whereas surfaces coated with micro ZnO additions had both superhydrophobic and self-cleaning properties. The hydrophobic coating, which contains ZnO particles of various sizes, also plays a vital role for the contact angle and specific surface energy, highlighting how crucial it is to acquire and create the right texture and surface chemistry. The synergistic effect of the processes on superhydrophobic and self-cleaning properties has been verified and discussed.

Similar content being viewed by others

References

H. Kramer, in Ullmann’s Polymers and Plastics: Products and Processes. ed. by B. Elvers (Wiley, Weinheim, 2016), p.781

B. Dholakiya, in Polyester. ed. by H.E.D.M. Saleh (Rijeka, Intech, 2012), p.167

P.W.R. Beaumont, C.H. Zweben, Comprehensive Composite Materials II, 2nd edn. (Elsevier, Amsterdam, 2018), pp.1–624

G. Acikbas, H. Gocmez, Mater. Test. 59, 11–12 (2017)

G. Acikbas, N. Calis Acikbas, Appl. Phys. A 127, 1–11 (2021)

A. Hozumi, O. Takai, Thin Solid Films 303, 1–2 (1997)

A. Nakajima, K. Abe, K. Hashimoto, T. Watanabe, Thin Solid Films 376, 1–2 (2000)

J.T. Han, Y. Jang, D.Y. Lee, J.H. Park, S.H. Song, D.Y. Ban, K. Cho, J. Mater. Chem. 15, 30 (2005)

H.Y. Erbil, A.L. Demirel, Y. Avcı, O. Mert, Science 299, 1377–1380 (2003)

J.T. Han, D.H. Lee, C.Y. Ryu, K. Cho, J. Am. Chem. Soc. 126, 15 (2004)

G. Acikbas, N Calis Acikbas. J. Asian Ceram. Soc. 9, 2 (2021)

S.S. Latthe, C. Terashima, K. Nakata, A. Fujishima, Molecules 19, 4 (2014)

L. Zhai, F.C. Cebeci, R.E. Cohen, M.F. Rubner, Nano Lett. 4, 7 (2004)

X. Wu, L. Zheng, D. Wu, Langmuir 21, 7 (2005)

G. Acikbas, N. Calis Acikbas, J. Am. Ceram. Soc. 105, 2 (2022)

S. Ozcan, G. Acikbas, N. Calis Acikbas, Appl. Surf. Sci. 438, 136 (2018)

G. Li, X. Wei, W. Wang, T. He, X. Li, Appl. Surf. Sci. 257, 1 (2010)

R.M.S. Attar, M. Alshareef, R.M. Snari, O. Alaysuy, A.M. Aldawsari, S. Abu-Melha, N.M. El-Metwaly, J. Mater. Res. Technol. 21, 11–12 (2022)

O.A.S. Adeakin, A.V. Popoola, K.K. Ajekwene, Fibers Polym. 23, 11 (2022)

H. Sun, Y. Wang, J. Chen, H. Hillborg, Silicone rubber with improved hydrophobicity. (Curran Associates Proceedings IEEE, 2015), https://ieeexplore.ieee.org/document/7352048. Accessed 23 July 2023

N.A. Patankar, Langmuir 29, 19 (2004)

M. Nosonovsky, B. Bhushan, Langmuir 24, 4 (2008)

M. Nosonovsky, B. Bhushan, Langmuir 11, 535–549 (2005)

L. Al-Naamani, S. Dobretsov, J. Dutta, J.G. Burgess, Chemosphere 168, 408–417 (2017)

M.S. Selim, H. Yang, F.Q. Wang, N.A. Fatthallah, Y. Huang, S. Kuga, Appl. Surf. Sci. 466, 40–50 (2019)

S. Ouir, H. Lachenani, F. Boudeffar, A. Bouaoua, H. Cheraga, F. Zermane, Z. Benmaamar, Appl. Phys. A 129, 1 (2019)

F.M. Fowkes, Ind. Eng. Chem. 56, 12 (1964)

D.K. Owens, R.C. Wendt, J. Appl. Polym. Sci. 13, 8 (1969)

D.H. Kaelble, J. Adhes. 2, 2 (1970)

Z. Zhan, Q. Zhang, F. Lu, Y. Liu, W. Liu, Z. Li, Q. Xie, AIP Adv. 9, 4 (2019)

C. Neinhuis, W. Barthlott, Ann. Bot. 79, 6 (1997)

E.H. Ishida, Channelling the forces of nature–human and earth conscious materials may create new waves. (Qualicer Ceramic tile quality, 2004), https://www.tib.eu/en/search/id/TIBKAT%3A392004119/QUALICER-2004-VIII-World-Congress-on-Ceramic-Tile. Accessed 21 July 2023

Funding

This work was financially supported by Mersin University, Scientific Research Fund [Project Number: 2022-1-TP2-4574].

Author information

Authors and Affiliations

Contributions

Gokhan Acikbas: Conceptualization, Validation, Visualization, Resources, Investigation, Methodology, Writing—original draft and review; Halil Hindi: Methodology.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Acikbas, G., Hindi, H. The Effect of a Composite Hydrophobic Coating with Zinc Oxide on the Characteristics of Polyester Matrix Composite Surfaces. J Inorg Organomet Polym 34, 419–429 (2024). https://doi.org/10.1007/s10904-023-02842-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-023-02842-2