Abstract

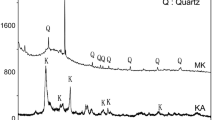

Geopolymers display a typical brittle mechanical behaviour with low ductility and low fracture toughness. These properties might represent a significant limitation for structural applicationsoffers steric entrapping of the organic molecule and thus structuring the solvated cations in the solution so as to enhance the hydrogen bonding between organic polymer and oxides in the inorganic framework. Research efforts have been done on the use of soluble organic polymer in alkali-activated geopolymers in general but studies on their role in phosphate elaborated geopolymers are rare. In view of the above, this research investigates the preparation of the Polyethylene glycol /Metakaolin geopolymer with silico alumino phosphate gel structure under ambient curing conditions and its performance compared with control samples cured at ambient as well at 80 °C temperature. The effect of PEG at different doses 0–3% (MKGP1, MKGP2 and MKGP3) in metakaolin reaction under phosphoric acid of molarity 10 M was studied by measuring compressive strength, flexural strength while tracing and identification of the formed gel network by employing X-ray diffraction, FTIR and Scanning electron microscopic analysis. Strength analysis showed an enhancement with about more than 50% gain in compressive strength in polymer-assisted samples than that of the control samples (MKGP0) which were 12.1 MPa at (ambient ) 18.8 MPa at 80 °C curing. XRD assemblages and FTIR spectral data proved an increased amorphous gel with PEG addition of up to 3% with the refinement of pores. Dense microstructure in blended samples was evident from SEM analysis. The total weight loss by heating the samples in TGA /DTA was found to be lower in PEG samples (29%) and for control mixes as high as 49%. The study results offer valuable organic-geopolymeric composites with better mechanical properties that can be applied for various potential applications as coatings, restoration and conservation domain.

Graphical Abstract

Similar content being viewed by others

References

J. Davidovits, Institut Geopolymer, 3rd printing (Institut Géopolymère, Saint-Quentin, 2008)

L. Provis, J.S. John, J. Van Deventer, Geopolymers: structures, processing, properties and industrial applications (CRC Press, Boca Raton, 2009)

J. Davidovits, Geopolymer Cem 21, 1–11 (2013)

P. Duxson, A. Fernández-Jiménez, J.L. Provis, G.C. Lukey, A. Palomo, J.S.J. van Deventer, J. Mater. Sci. 42(9), 2917–2933 (2006). https://doi.org/10.1007/s10853-006-0637-z

N.B. Singh, S.K. Saxena, M. Kumar, S. Rai, Mater. Today Proc. 15, 364–370 (2019). https://doi.org/10.1016/j.matpr.2019.04.095

Y.S. Wang, Y. Alrefaei, J.G. Dai, Front. Mater. (2019). https://doi.org/10.3389/fmats.2019.00106

A. Palomo, M.T. Blanco Varela, M.L. Granizo, F. Puertas, T. Vázquez, M.W. Grutzeck, Cement Concr. Res. 29, 997–1004 (1999). https://doi.org/10.1016/S0008-8846(99)00074-5

D.S. Perera, J.V. Hanna, J. Davis, M.G. Blackford, B.A. Latella, Y. Sasaki, E.R. Vance, J. Mater. Sci. 43(19), 6562–6566 (2008). https://doi.org/10.1007/s10853-008-2913-6

M. Alhawat, A. Ashour, G. Yildirim, A. Aldemir, M. Sahmaran, J. Build. Eng. 50, 104104 (2022). https://doi.org/10.1016/j.jobe.2022.104104

Y.H.M. Amran, R. Alyousef, H. Alabduljabbar, M. El-Zeadani, J. Clean. Prod. (2019). https://doi.org/10.1016/j.jclepro.2019.119679

V. Bednarik, J. Melar, M. Vondruska, R. Slavik, J. Inorg. Organomet. Polym. Mater. 21(1), 9–14 (2010). https://doi.org/10.1007/s10904-010-9424-z

M. Zribi, S. Baklouti, Polym. Bull. (2021). https://doi.org/10.1007/s00289-021-03829-0

A. Gharzouni, E. Joussein, B. Samet, S. Baklouti, S. Rossignol, J. Non-cryst. Solids 410, 127–134 (2015). https://doi.org/10.1016/j.jnoncrysol.2014.12

A. Gharzouni, L. Vidal, N. Essaidi, E. Joussein, S. Rossignol, Mater. Design 94, 221–229 (2016). https://doi.org/10.1016/j.matdes.2016.01.043

L. Liu, X. Cui, Y. He, S. Liu, S. Gong, Mater. Lett. 66(1), 10–12 (2012). https://doi.org/10.1016/j.matlet.2011.08.043

J. Davidovits, J. Therm. Anal. 35(2), 429–441 (1989). https://doi.org/10.1007/bf01904446

Y.S. Wang, J.L. Provis, J.G. Dai, Cem. Concr. Compos. 93, 186–195 (2018). https://doi.org/10.1016/j.cemconcomp.2018.07

Y.S. Wang, J.G. Dai, Z. Ding, W.T. Xu, Mater. Lett. 190, 209–212 (2017). https://doi.org/10.1016/j.matlet.2017.01.022

M. Mouna Sellami, M. Barre, M. Toumi, J. Inorg. Organomet. Polym. Mater. 30, 3126–3131 (2020)

A.S. Wagh, Advances in Ceramic Matrix Composites X: Proceedings of the 106th Annual Meeting of the American Ceramic Society (Indianapolis, IN). Vol. 107. (2004)

M. Zribi, B. Samet, S. Baklouti, J. Solid State Chem. 281, 121025 (2020). https://doi.org/10.1016/j.jssc.2019.121025

M. habbouchi, K. Hosni, M. Mezni, C. Zanelli, M. Doggy, M. Dondi, E. Srasra, Appl. Clay Sci. 146, 510–516 (2017). https://doi.org/10.1016/j.clay.2017.07.00

M. Zribi, B. Samet, S. Baklouti, J. Non-Cryst. Solids 511, 62–67 (2019). https://doi.org/10.1016/j.jnoncrysol.2019.01

L. Gao, Y. Zheng, Y. Tang, J. Yu, X. Yu, B. Liu, Heliyon 6(4), e03853 (2020). https://doi.org/10.1016/j.heliyon.2020.e03853

T. Dong, S. Xie, J. Wang, Z. Chen, Q. Liu, Q J. Aust. Ceram. Soc. (2019). https://doi.org/10.1007/s41779-019-00376-w

H.I. Riyap, F. Kenne Tazune, D. Fotio, H.K. Tchakoute, C.P. NanseuNjiki, C.H. Ruscher, J. Inorg. Organomet. Polym. Mater. 31, 3301–3323 (2021). https://doi.org/10.1007/s10904-021-01949-8

H.K. Tchakouté, C.H. Rüscher, E. Kamseu, F. Andreola, C. Leonelli, Appl. Clay Sci. 147, 184–194 (2017). https://doi.org/10.1016/j.clay.2017.07.036

H.I. Riyap, B.K. Ngongang, H.K. Tchakouté et al., Silicon 14, 10535–10558 (2022). https://doi.org/10.1007/s12633-022-01786-5

R. Gupta, P. Bhardwaj, D. Mishra, M. Prasad, S.S. Amritphale, J. Inorg. Organomet. Polym. Mater. 27(2), 385–398 (2016). https://doi.org/10.1007/s10904-016-0461-0

O.M. Jensen, P.F. Hansen, Cem. Concr. Res. 32(6), 973–978 (2002). https://doi.org/10.1016/s0008-8846(02)00737-8

V. Mechtcherine, H.W. Reinhardt, Application of Super Absorbent Polymers (SAP) in Concrete Construction (Springer, Cham, 2012)

O. Mikhailova, P. Rovnaník, Proc. Eng. 151, 222–228 (2016). https://doi.org/10.1016/j.proeng.2016.07.379

V. Mathivet, J. Jouin, A. Gharzouni, I. Sobrados, H. Celerier, S. Rossignol, M. Parlier, J. Non-cryst. Solids 512, 90–97 (2019). https://doi.org/10.1016/j.jnoncrysol.2019.02.025

H. Lin, H. Liu, Y. Li, X. Kong, Cem. Concr. Res. 144, 106425 (2021). https://doi.org/10.1016/j.cemconres.2021.106425

C. Nobouassia Bewa, H.K. Tchakouté, D. Fotio, C.H. Rüscher, E. Kamseu, C. Leonelli, J. Asian. Ceam. Soc. (2018). https://doi.org/10.1080/21870764.2018.1507660

J. Jouin, H. Celerier, L. Ouamara, N. Tessier-Doyen, S. Rossignol, J. Am. Ceram. Soc. 104(10), 5445–5456 (2021). https://doi.org/10.1111/jace.17929

A. Katsiki, T. Hertel, T. Tysmans, Y. Pontikes, H. Rahier, Materials 12(3), 442 (2019). https://doi.org/10.3390/ma12030442

X. Zhang, J. Qiao, W. Zhang, F. Cheng, Z. Yin, Z. Huang, X. Min, J. Mater. Sci. 53(18), 13067–13080 (2018). https://doi.org/10.1007/s10853-018-2531-x

X. Cui, L. Liu, Y. He, J. Chen, J. Zhou, Mater. Chem. Phys. 130(1–2), 1–4 (2011). https://doi.org/10.1016/j.matchemphys.2011.06.039

H. Celerier, J. Jouin, N. Tessier-Doyen, S. Rossignol, J. Non-cryst. Solids (2018). https://doi.org/10.1016/j.jnoncrysol.2018.09.005

N. Vanitha, R. Jeyalakshmi, Inorg. Chem. Commun. 153, 110758 (2023). https://doi.org/10.1016/j.inoche.2023.110758

N. Vanitha, T. Revathi, M. Sivasakthi, R. Jeyalakshmi, J. Solid State Chem. 312, 123188 (2022). https://doi.org/10.1016/j.jssc.2022.123188

H.K. Tchakouté, C.H. Rüscher, S. Kong, E. Kamseu, C. Leonelli, J. Solgel Sci. Technol. 78(3), 492–506 (2016). https://doi.org/10.1007/s10971-016-3983-6

R.A. Khan, C. Gupta, Int. J. Res. Advent Technol. (IJRAT) 11, 1–7 (2020)

Acknowledgements

The authors greatly acknowledge the utilization of facilities provided by DST-FIST, Department of Chemistry and SEM facility by NRC, SRM Institute of Science and Technology, Kattankulathur, India. Authors thank the authorities of SRMIST for funding to the research scholars.

Funding

This work was supported by the Department of Science and Technology, the Government of India (GOI), under the grant DST/TDT/WMT/2017 14/03/18, GOI., Kuttuva silicates, Madurai.

Author information

Authors and Affiliations

Contributions

NV: Investigation, Methodology, Data curation, and original draft preparation. RJ: Conceptualization, Editing and Supervision, Funding acquisition.

Corresponding author

Ethics declarations

Competing Interests

All the authors declare that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vanitha, N., Jeyalakshmi, R. The Role of Polyethylene Glycol, a Water Entrainer on Characteristics of Silico Alumino Phosphate Geopolymer to Harvest Enhanced Gel Phase and Stability. J Inorg Organomet Polym 33, 2835–2847 (2023). https://doi.org/10.1007/s10904-023-02715-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-023-02715-8