Abstract

The advantage of the concurrent development in polymers flame retardant is illustrated by the hybrid material technology of flame retardants, which, as opposed to conventional flame retardants, blends distinct elements into a whole. Layered zinc hydroxide, sodium dodecyl sulfate, borate ion, and polydimethylsiloxane were used to make a flame retardant composite, a new organic–inorganic hybrid material as a flame retardant. Using analysis methods, the structures of materials were investigated following synthesis. The interlayer space of the layered zinc hydroxide was studied for the intercalation of ions, according to the X-ray diffraction studies. The chemical structure of produced compounds was assessed with energy dispersive spectrum and fourier transforms infrared spectroscopy. The morphology of the synthesized materials was identified using emission scanning electron microscopy. The thermal resistance of the synthesized samples and coating samples was measured by thermogravimetric analysis. By adding a little amount of flame retardant composite flame retardant, the fire danger of epoxy resin was significantly decreased. According to the plate temperature and flammability test experiment, flame retardant composite with 0.075% w/w led to showed that the synergistic role of the flame retardant composite compound including zinc, borate ions, and also the polydimethylsiloxane played a significant role in reducing the risks of epoxy resin hazard flaming as well as reducing heat and damage to the metal substrate.

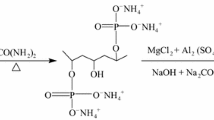

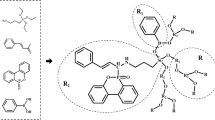

Graphical Abstract

Similar content being viewed by others

References

O. Dagdag, A.E. Bachiri, O. Hamed, R. Haldhar, C. Verma, E. Ebenso, M.E. Gouri, J. Inorg. Organomet. Polym Mater. 3240, 31 (2021)

N. Wen, W. Zeng, Y. Yang, Z. Yang, H. Li, X. Li, Z. Li, H. Ding, Z. Lei, J. Inorg. Organomet. Polym Mater. 412, 32 (2022)

Y. Yang, D.Y. Wang, R.K. Jian, Z. Liu, G. Huang, Prog. Org. Coat. 107316, 175 (2023)

Q. Chen, L. Liu, A. Zhang, W. Wang, Z. Wang, J. Zhang, J. Feng, S. Huo, X. Zeng, P. Song, Chem. Eng. J. 140424, 454 (2023)

T.A. Nguyen, Q.T. Nguyen, T.P. Bach, J. Chem. (2019). https://doi.org/10.1155/2019/3105205

T.A. Nguyen, Q.T. Nguyen, X.C. Nguyen, V.H. Nguyen, J. Chem. 2019, 2635231 (2019). https://doi.org/10.1155/2019/2635231

N. Nguyen, Int. J. Chem. Eng. 1, 2021 (2021)

T.A. Nguyen, J. Chem. 2021, 3287733 (2021). https://doi.org/10.1155/2021/3287733

T.A. Nguyen, T.T.T. Bui, J. Nanomater. (2021). https://doi.org/10.1155/2021/2862426

M. Abniki, A. Moghimi, F. Azizinejad, J. Serbian Chem. Soc. 1223, 85 (2020)

P. Li, L. Dang, Y. Li, S. Lan, D. Zhu, Mater. Des. 110608, 217 (2022)

A.M. Elbarbary, M.A. Elhady, Y.H. Gad, J. Inorg. Organomet. Polym Mater. 4039, 32 (2022)

W. Xu, X. Wang, Y. Wu, W. Li, C. Chen, J. Hazard. Mater. 138, 363 (2019)

H. Gan, S.M. Seraji, J. Zhang, S.R. Swan, S. Issazadeh, R.J. Varley, React. Funct. Polym. 104743, 157 (2020)

S. Zhu, W. Gong, J. Luo, X. Meng, Z. Xin, J. Wu, Z. Jiang, Polymers 1304, 11 (2019)

Z. Muda, N. Hashim, I. Md Isa, S. Mustafar, S.A. Bakar, M. Mamat, M.Z. Hussein, Mater. Res. Innovations 279, 24 (2020)

K.M. Parida, M. Sahoo, S. Singha, J. Catal. 161, 276 (2010)

M. Abniki, A. Moghimi, F. Azizinejad, J. Chin. Chem. Soc. 343, 68 (2021)

W. Stählin, H.R. Oswald, Acta Crystallogr. Sect. B: Struct. Crystallogr. Cryst. Chem. 860, 26 (1970)

M.V. Sasi Kumar, B. Rajeswara Reddy, A. Balakrishna, Y.C. Ratnakaram, J. Taibah Univ. Sci. 593, 11 (2017)

Fan S, Zhang X, Lu Y, Gao Y, 2018 12th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), IEEE, p. 888–891 2018

A.N. Ay, B. Zumreoglu-Karan, A.G. Kalinichev, V. Rives, R. Trujillano, A. Temel, J. Porous Mater. 735, 27 (2020)

M.T. Nazir, B.T. Phung, G.H. Yeoh, G. Yasin, S. Akram, M.S. Bhutta, A. Mehmood, S. Hussain, S. Yu, I. Kabir, Bull. Mater. Sci. 1, 43 (2020)

M. Abniki, B. Shirkavand Hadavand, F. Najafi, I. Ghasedi, J. Macromol. Sci. 59(6), 411–420 (2022)

Nazarenko OB, Melnikova TV, Visakh PM, Journal of Physics: Conference Series, IOP Publishing, p. 012040 2016

Z. Xu, Z. Chu, L. Yan, J. Therm. Anal. Calorim. 1241, 133 (2018)

Z. Kovačević, S. Flinčec Grgac, S. Bischof, Polymers 741, 13 (2021)

J.W. Gilman, C.L. Jackson, A.B. Morgan, R. Harris, E. Manias, E.P. Giannelis, M. Wuthenow, D. Hilton, S.H. Phillips, Chem. Mater. 1866, 12 (2000)

Q. Liu, D. Wang, Z. Li, Z. Li, X. Peng, C. Liu, Y. Zhang, P. Zheng, Materials. 2145, 13 (2020)

B.K. Kandola, B. Biswas, D. Price, A.R. Horrocks, Polym. Degrad. Stab. 144, 95 (2010)

Author information

Authors and Affiliations

Contributions

The initial planning was done by Dr. Milad Abniki and Dr. Farhood Najafi. Laboratory work was done by Dr. Milad Abniki. The interpretation and analysis of the results was done by Dr. Behzad Shirkavand Hadavand. The main manuscript text was written by Dr. Milad Abniki, Dr. Behzad Shirkavand Hadavand, and Dr. Farhood Najafi. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abniki, M., Shirkavand Hadavand, B. & Najafi, F. Fabrication of Layered Hydroxide Composite with Polydimethylsiloxane Hydroxy-Terminated for Epoxy Resin Flame Retardancy. J Inorg Organomet Polym 33, 1946–1954 (2023). https://doi.org/10.1007/s10904-023-02630-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-023-02630-y