Abstract

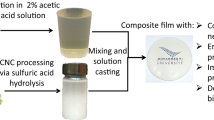

Mitigating environmental pollution, which adversely affects humans, wildlife, and habitat, has been attracting increasing attention worldwide, especially with reference to the importance of using composite films. In this study, composite films consisting of cellulose, chitosan, and gelatine were analysed and characterized. It was fabricated via a solution casting method. The cellulose extracted from the whole stem, cortex, and pith of Napier grass with 4, 8, 12, and 16% alkali concentrations were used to produce the composite films. Based on the thermogravimetric analysis, mechanical analysis, Fourier-transform infrared spectroscopy (FTIR) analysis, X-ray diffraction (XRD) analysis, and scanning electron microscopy (SEM) observation, it was confirmed that the interaction of cellulose of Napier grass, chitosan and gelatine had improve the thermal behaviour, strength, composition, crystallinity, and morphology of composite films. The composite films using 8% alkali-treated cellulose from the whole stem had an ordered structure with 2θ = 22.68°. Furthermore, it contained the highest final residue (74.85%) and tensile strength of 4.58 ± 0.373 MPa.

Similar content being viewed by others

References

P. Chaudhary, F. Fatima, A. Kumar, Relevance of nanomaterials in food packaging and its advanced future prospects. J. Inorg. Organomet. Polym. Mater. 30, 5180–5192 (2020). https://doi.org/10.1007/s10904-020-01674-8

G. Mamatha, P. Sowmya, D. Madhuri, N. Mohan Babu, D. Suresh Kumar, G. Vijaya Charan, K. Varaprasad, K. Madhukar, Antimicrobial cellulose nanocomposite films with in situ generations of bimetallic (Ag and Cu) nanoparticles using Vitex negundo leaves extract. J. Inorg. Organomet. Polym. Mater. 31, 802–815 (2021). https://doi.org/10.1007/s10904-020-01819-9

J. Lucenius, K. Parikka, M. Österberg, Nanocomposite films based on cellulose nanofibrils and water-soluble polysaccharides. React. Funct. Polym. 85, 167–174 (2014). https://doi.org/10.1016/j.reactfunctpolym.2014.08.001

G. Zhao, X. Lyu, J. Lee, X. Cui, W.-N. Chen, Biodegradable and transparent cellulose film prepared eco-friendly from durian rind for packaging application. Food Packag. Shelf Life 21, 100345 (2019). https://doi.org/10.1016/J.FPSL.2019.100345

E. Kabir, R. Kaur, J. Lee, K.H. Kim, E.E. Kwon, Prospects of biopolymer technology as an alternative option for non-degradable plastics and sustainable management of plastic wastes. J. Clean. Prod. (2020). https://doi.org/10.1016/j.jclepro.2020.120536

H. Haghighi, F. Licciardello, P. Fava, H.W. Siesler, A. Pulvirenti, Recent advances on chitosan-based films for sustainable food packaging applications. Food Packag. Shelf Life 26, 100551 (2020). https://doi.org/10.1016/j.fpsl.2020.100551

R. Ning, M. Takeuchi, J.M. Lin, T. Saito, A. Isogai, Influence of the morphology of zinc oxide nanoparticles on the properties of zinc oxide/nanocellulose composite films. React. Funct. Polym. 131, 293–298 (2018). https://doi.org/10.1016/j.reactfunctpolym.2018.08.005

S. Kumar, P. Singh, S.K. Gupta, J. Ali, S. Baboota, Biodegradable and recyclable packaging materials: a step towards a greener future, in: Encyclopedia of Renewable and Sustainable Materials (Elsevier, Amsterdam, 2020), pp. 328–337. https://doi.org/10.1016/b978-0-12-803581-8.10934-8

I.S. Jahit, N.N.M. Nazmi, M.I.N. Isa, N.M. Sarbon, Preparation and physical properties of gelatin/CMC/chitosan composite films as affected by drying temperature. Int. Food Res. J. 23(23), 1068–1074 (2016)

C. Sharma, N.K. Bhardwaj, P. Pathak, Ternary nano-biocomposite films using synergistic combination of bacterial cellulose with chitosan and gelatin for tissue engineering applications. J. Biomater. Sci. Polym. Ed. 32, 166–188 (2021). https://doi.org/10.1080/09205063.2020.1822122

M. Abdelraof, M.M. Farag, Z.M. Al-Rashidy, H.Y.A. Ahmed, H. El-Saied, M.S. Hasanin, Green synthesis of bioactive hydroxyapatite/cellulose composites from food industrial wastes. J. Inorg. Organomet. Polym. Mater. 32, 4614–4626 (2022). https://doi.org/10.1007/s10904-022-02462-2

B. Rohmawati, F.A. Nata Sya’idah, R. Rhismayanti, D. Alighiri, W. Tirza Eden, Synthesis of bioplastic-based renewable cellulose acetate from teak wood (Tectona grandis) biowaste using glycerol-chitosan plasticizer. Orient. J. Chem. 34, 1810–1816 (2018)

A.M. Mansor, J. Shiun Lim, F.N. Ani, H. Hashim, W. Shin Ho, Characteristics of cellulose, hemicellulose and lignin of MD2 pineapple biomass. Chem. Eng. Trans. 72, 79–84 (2019). https://doi.org/10.3303/CET1972014

S. Rasila, A.M. Rasli, I. Ahmad, A.M. Lazim, A. Hamzah, Extraction and characterization of cellulose from agricultural residue-oil palm fronds. Malaysian J. Anal. Sci. 21, 1065–1073 (2017)

P. Penjumras, R.B.A. Rahman, R.A. Talib, K. Abdan, Extraction and characterization of cellulose from durian rind. Agric. Agric. Sci. Procedia 2, 237–243 (2014). https://doi.org/10.1016/j.aaspro.2014.11.034

C.A.O. Midega, J.O. Pittchar, J.A. Pickett, G.W. Hailu, Z.R. Khan, A climate-adapted push-pull system effectively controls fall armyworm, Spodoptera frugiperda (J E Smith), in maize in East Africa. Crop Prot. 105, 10–15 (2018). https://doi.org/10.1016/j.cropro.2017.11.003

H. Izadi-Vasafi, F. Ghayoumi, S. Karbasizadeh-Esfahani, M. Ghafghazi, Comparing the effect of sodium-based and calcium-based crosslinkers on the swelling, mechanical and rheological properties of chitosan/gelatin/starch films. J. Macromol. Sci. Part B Phys. 59, 331–343 (2020). https://doi.org/10.1080/00222348.2020.1714854

S. Kumar, A. Shukla, P.P. Baul, A. Mitra, D. Halder, Biodegradable hybrid nanocomposites of chitosan/gelatin and silver nanoparticles for active food packaging applications. Food Packag. Shelf Life 16, 178–184 (2018). https://doi.org/10.1016/j.fpsl.2018.03.008

T.S.M. Kumar, N. Rajini, K. Obi Reddy, A. Varada Rajulu, S. Siengchin, N. Ayrilmis, All-cellulose composite films with cellulose matrix and Napier grass cellulose fibril fillers. Int. J. Biol. Macromol. 112, 1310–1315 (2018). https://doi.org/10.1016/j.ijbiomac.2018.01.167

T.N.T. Rohadi, M.J.M. Ridzuan, M.S.A. Majid, A. Khasri, M.H. Sulaiman, Isolation and characterisation of cellulose from cortex, pith and whole of the Pennisetum purpureum: effect of sodium hydroxide concentration. J. Mater. Res. Technol. 9, 15057–15071 (2020). https://doi.org/10.1016/j.jmrt.2020.10.102

A.T. Mart, A. Gutie, Structural characterization of the lignin in the cortex and pith of elephant grass (Pennisetum purpureum) stems. J. Agric. Food Chem. 60, 3619–3634 (2012). https://doi.org/10.1021/jf300099g

S.T. Cholake, R. Rajarao, P. Henderson, R.R. Rajagopal, V. Sahajwalla, Composite panels obtained from automotive waste plastics and agricultural macadamia shell waste. J. Clean. Prod. 151, 163–171 (2017). https://doi.org/10.1016/j.jclepro.2017.03.074

ASTM D882-02, Standard Test Method for Tensile Properties of Thin Plastic Sheeting. West Conshohocken, 2002. https://doi.org/10.1520/D0882-02

A.D. French, Increment in evolution of cellulose crystallinity analysis. Cellulose 27, 5445–5448 (2020). https://doi.org/10.1007/s10570-020-03172-z

A.D. French, M. Santiago Cintrón, Cellulose polymorphy, crystallite size, and the Segal Crystallinity Index. Cellulose 20, 583–588 (2013). https://doi.org/10.1007/s10570-012-9833-y

N. Ramakrishnan, S. Sharma, A. Gupta, B.Y. Alashwal, Keratin based bioplastic film from chicken feathers and its characterization. Int. J. Biol. Macromol. 111, 352–358 (2018). https://doi.org/10.1016/j.ijbiomac.2018.01.037

M.R. Amin, M.A. Chowdhury, M.A. Kowser, Characterization and performance analysis of composite bioplastics synthesized using titanium dioxide nanoparticles with corn starch. Heliyon 5, e02009 (2019). https://doi.org/10.1016/j.heliyon.2019.e02009

S.C. Koay, V. Subramanian, M.Y. Chan, M.M. Pang, K.Y. Tsai, K.H. Cheah, Preparation and characterization of wood plastic composite made up of durian husk fiber and recycled polystyrene foam. MATEC Web Conf. 152, 02019 (2018). https://doi.org/10.1051/matecconf/201815202019

V. Bátori, M. Jabbari, D. Åkesson, P.R. Lennartsson, M.J. Taherzadeh, A. Zamani, Production of pectin-cellulose biofilms: a new approach for citrus waste recycling. Int. J. Polym. Sci. (2017). https://doi.org/10.1155/2017/9732329

R.F. Santana, R.C.F. Bonomo, O.R.R. Gandolfi, L.B. Rodrigues, L.S. Santos, A.C. Dos Santos Pires, C.M. Veloso, Characterization of starch-based bioplastics from jackfruit seed plasticized with glycerol. J. Food Sci. Technol. 55, 278–286 (2018)

A.S. Giwa, H. Xu, J. Wu, Y. Li, F. Chang, X. Zhang, Z. Jin, B. Huang, K. Wang, Sustainable recycling of residues from the food waste (FW) composting plant via pyrolysis: thermal characterization and kinetic studies. J. Clean. Prod. 180, 43–49 (2018). https://doi.org/10.1016/j.jclepro.2018.01.122

M. Lubis, M. Bangun Harahap, M. Hendra, S. Ginting, M. Sartika, H. Azmi, Production of bioplastic from avocado seed starch reinforced with microcrystalline cellulose from sugar palm fibers. J. Eng. Sci. Technol. 13, 381–393 (2018)

A. Muhammad, A. Roslan, S.N.A. Sanusi, M.Q. Shahimi, N.Z. Nazari, Mechanical properties of bioplastic form cellulose nanocrystal (CNC) mangosteen peel using glycerol as plasticizer. J. Phys. Conf. Ser. 1349, 12099 (2019). https://doi.org/10.1088/1742-6596/1349/1/012099

M.J.M. Ridzuan, M.S. Abdul Majid, A. Khasri, K.S. Basaruddin, A.G. Gibson, Effect of moisture exposure and elevated temperatures on impact response of Pennisetum purpureum/glass-reinforced epoxy (PGRE) hybrid composites. Compos. Part B Eng. 160, 84–93 (2019). https://doi.org/10.1016/j.compositesb.2018.10.029

Isroi, A. Cifriadi, T. Panji, N.A. Wibowo, K. Syamsu, 2017. Bioplastic production from cellulose of oil palm empty fruit bunch, in: IOP Conf. Ser. Earth Environ. Sci. 65, 012011. https://doi.org/10.1088/1755-1315/65/1/012011

M.K. Marichelvam, M. Jawaid, M. Asim, Corn and rice starch-based bio-plastics as alternative packaging materials. Fibers 7, 32 (2019). https://doi.org/10.3390/fib7040032

H. Hermansyah, R. Carissa, M.B. Faiz, P. Deni, Food grade bioplastic based on corn starch with banana pseudostem fibre/bacterial cellulose hybrid filler. Front. Chem. Eng. Metall. Eng. Mater. III 997, 158–168 (2014). https://doi.org/10.4028/www.scientific.net/AMR.997.158

R. Gurram, P.F. Souza Filho, M.J. Taherzadeh, A. Zamani, A solvent-free approach for production of films from pectin and fungal biomass. J. Polym. Environ. 26, 4282–4292 (2018). https://doi.org/10.1007/s10924-018-1300-x

N.A. Ismail, S. Mohd Tahir, N. Yahya, M.F. Abdul Wahid, N.E. Khairuddin, I. Hashim, N. Rosli, M.A. Abdullah, Synthesis and characterization of biodegradable starch-based bioplastics. Mater. Sci. Forum 846, 673–678 (2016)

M.C. Etty, S. D’Auria, S. Shankar, S. Salmieri, J. Coutu, A. Baraketi, M. Jamshidan, C. Fraschini, M. Lacroix, New immobilization method of anti-PepD monoclonal antibodies for the detection of Listeria monocytogenes p60 protein—Part a: optimization of a crosslinked film support based on chitosan and cellulose nanocrystals (CNC). React. Funct. Polym. 146, 104313 (2020). https://doi.org/10.1016/j.reactfunctpolym.2019.06.021

M.M. Siagian, P. Tarigan, Production of starch based bioplastic from cassava peel reinforced with microcrystalline celllulose avicel PH101 using sorbitol as plasticizer. J. Phys. Conf. Ser. (2016). https://doi.org/10.1088/1742-6596/710/1/012012

M. Prochoń, A. Marzec, B. Szadkowski, Preparation and characterization of new environmentally friendly starch-cellulose materials modified with casein or gelatin for agricultural applications. Materials (Basel). 12, 1684 (2019)

X. Xu, J. Yu, C. Liu, G. Yang, L. Shi, X. Zhuang, Xanthated chitosan/cellulose sponges for the efficient removal of anionic and cationic dyes. React. Funct. Polym. 160, 104840 (2021). https://doi.org/10.1016/j.reactfunctpolym.2021.104840

N.Johnsson, F. Steuer, Bioplastic material from microalgae extraction of starch and PHA from microalgae to create a bioplastic material, Degree Project Technology, 2018.

B. Jiang, S. Li, Y. Wu, J. Song, S. Chen, X. Li, H. Sun, Preparation and characterization of natural corn starch-based composite films reinforced by eggshell powder preparation and characterization of natural corn starch-based composite films reinforced by eggshell powder. CyTA-Journal Food 16, 1045–1054 (2018). https://doi.org/10.1080/19476337.2018.1527783

A.D. French, Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21, 885–896 (2014). https://doi.org/10.1007/s10570-013-0030-4

B.Y. Alashwal, M. Saad Bala, A. Gupta, S. Sharma, P. Mishra, Improved properties of keratin-based bioplastic film blended with microcrystalline cellulose: a comparative analysis. J. King Saud Univ. Sci. 32, 853–857 (2020). https://doi.org/10.1016/j.jksus.2019.03.006

Acknowledgements

The authors appreciatively thank the Universiti Malaysia Perlis (UniMAP), Universiti Teknologi Mara (UiTM) Shah Alam, and International Islamic University Malaysia (IIUM) for the support of their facility in conducting this research.

Funding

This work was supported by the Ministry of Education, Malaysia through the Fundamental Research Grant Scheme (Ref: FRGS/1/2020/TK0/UNIMAP/02/18).

Author information

Authors and Affiliations

Contributions

MJMR, TNTR and MSAM designed the entire story in this manuscript, performed all tests and data analysis. AA, FM, SMS were designed and revised the manuscript. All authors discussed the methods, results and checked the manuscripts.

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rohadi, T.N.T., Ridzuan, M.J.M., Majid, M.S.A. et al. Synthesis and Characterization of Composite Film Based on Cellulose of Napier Grass Incorporated with Chitosan and Gelatine for Packaging Material. J Inorg Organomet Polym 33, 1134–1146 (2023). https://doi.org/10.1007/s10904-023-02563-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-023-02563-6