Abstract

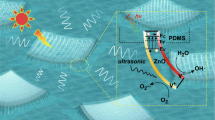

This study was aimed at addressing the present challenge in self-controlled catalysts, about how to furnish the catalysts with self-governed catalytic ability in water. This objective was met by constructing a polymer composite reactor inspired from marine mussels, made of an aquatically autonomous polymer and encapsulated metal nanoparticles. The aquatically autonomous properties at the polymer support, in combination with the catalytic ability of metal nanoparticles, allowed the reactor to run catalysis with aquatically ‘autonomous’ access, which led to the occurrence of aquatically self-governed catalytic ability. This reactor showed poor catalytic reactivity in water at relatively low temperatures due to the ‘closed’ polymeric networks, which blocked access to the encapsulated metal nanoparticles. This reactor showed, however, significant reactivity in water at relatively high temperatures in response to the ‘openness’ of the access. Unlike the switchable catalysis at reported catalytic reactors which usually involved conventional hydrophilic/hydrophobic transition and the leaching of metal nanoparticles, the switchable catalysis at this reactor ran naturally with the aquatically autonomous access that did not involve any hydrophilic/hydrophobic transition and the leaching of metal nanoparticles. This protocol suggested opportunities for developing robust smart catalysts for aquatic chemical processes.

Similar content being viewed by others

References

A.J. Teator, D.N. Lastovickova, C.W. Bielawski, Chem. Rev. 116, 1969–1992 (2016)

J. Zhang, M. Zhang, K. Tang, F. Verpoort, T. Sun, Small 10, 32–46 (2014)

G. Liu, D. Wang, F. Zhou, W. Liu, Small 11, 2807–2816 (2015)

C.L. Zhang, F.H. Cao, J.L. Wang, Z.L. Yu, J. Ge, Y. Lu, Z.H. Wang, S.H. Yu, ACS Appl. Mater. Interfaces 9, 24857–24860 (2017)

A. Lu, R.K. O’Reilly, Curr. Opin. Biotechnol. 24, 639–645 (2013)

G. Prieto, H. Tüysüz, N. Duyckaerts, J. Knossalla, G.H. Wang, F. Schüth, Chem. Rev. 116, 14056–14119 (2016)

B.P. Lee, S. Konst, Adv. Mater. 26, 3415–3419 (2014)

W. Wei, L. Petrone, Y. Tan, H. Cai, J.N. Israelachvili, A. Miserez, J.H. Waite, Adv. Funct. Mater. 26, 3496–3507 (2016)

S.A. Mian, L.M. Yang, L.C. Saha, E. Ahmed, M. Ajmal, E. Ganz, Langmuir 30, 6906–6914 (2014)

G.P. Maier, M.V. Rapp, J.H. Waite, J.N. Israelachvili, A. Butler, Science 349, 628–632 (2015)

Y.B. Lee, Y.M. Shin, E.M. Kim, J.Y. Lee, J. Lim, S.K. Kwon, H. Shin, J. Mater. Chem. B 4, 6012–6022 (2016)

H. Lee, Y.M. Ha, S.H. Lee, Y. Ko, H. Muramatsu, Y.A. Kim, M. Parke, Y.C. Jung, RSC Adv. 6, 87044–87048 (2016)

B.K. Ahn, D.W. Lee, J.N. Israelachvili, J.H. Waite, Nat. Mater. 13, 867–872 (2014)

M.A. North, C.A. Del Grosso, J.J. Wilker, ACS Appl. Mater. Interfaces 9, 7866–7872 (2017)

D. Bambusi, Commun. Math. Phys. 353, 353–378 (2017)

S. Patchkovskii, H.G. Muller, Comput. Phys. Commun. 199, 153–169 (2016)

F. Herbst, D. Döhler, P. Michael, W.H. Binde, Macromol. Rapid Commun. 34, 203–220 (2013)

Y. Zhou, M. Zhu, S. Li, J. Mater. Chem. A 2, 6834–6839 (2014)

S. Li, Y. Ge, A.P.F. Turner, Adv. Funct. Mater. 21, 1194–1200 (2011)

C. Deraedt, L. Salmon, S. Gatard, R. Ciganda, R. Hernandez, J. Ruiza, D. Astruc, Chem. Commun. 50, 14194–14196 (2014)

S. Li, Y. Luo, M. Whitcombe, S.A. Piletsky, J. Mater. Chem. A 1, 15102–15109 (2013)

Y. Han, X. Yuan, M. Zhu, S. Li, M. Whitcombe, S.A. Piletsky, Adv. Funct. Mater. 24, 4996–5001 (2014)

X. Xu, B. Bai, C. Ding, H. Wang, Y. Suo, Ind. Eng. Chem. Res. 54, 3268–3278 (2015)

B. Peng, X. Yuan, M. Zhu, S. Li, Polym. Chem. 5, 562–566 (2014)

W. Wei, T. Zhou, S. Wu, X. Shen, M. Zhu, S. Li, RSC Adv. 8, 1610–1620 (2018)

R. Luo, M. Zhu, X. Shen, S. Li, J. Catal. 331, 49–56 (2015)

Acknowledgements

The authors want to express their gratitude to the National Natural Science Foundation of China (Nos. 51473070 and 21403091). Thanks also should be expressed to the Jiangsu Province for support under the innovation/entrepreneurship program (Surencaiban [2015]26).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bao, X., Zuo, C., Zhou, Q. et al. Polymer Composite Reactor with “Autonomous” Access for Aquatically Self-Governed Catalytic Ability. J Inorg Organomet Polym 28, 1511–1519 (2018). https://doi.org/10.1007/s10904-018-0847-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-018-0847-2