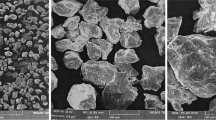

A systematic study of detonation deposition of wear-resistant coatings made of composite powders based on chromium carbide used to harden parts operating at temperatures up to 870°C is carried out. An integrated analysis of the characteristics of coatings produced from powders of Russian and foreign manufacturers was carried out. A composite in the form of mechanical mixture and powders obtained by cladding and the Spray–Dry method are considered. Using a numerical code, the acceleration and heating of particles of the sprayed powder are calculated and the optimal spraying modes are determined. The hardness, porosity, wear resistance, and bond strength of the resulting coatings were considered. A comparative characterization of residual stresses has been carried out. The influence of the spraying distance in the range from 50 to 400 mm and of the inclination angle of the treated surface up to 60° has been studied.

It is shown that in the case of dual-fuel mixture spraying, the density and wear resistance of coating increase and residual tensile stresses are completely eliminated. The adhesion of the resulting coatings exceeds 150 MPa, and the abrasive resistance of the best coating is characterized by a specific wear of about 3 mm3/1000 rpm according to the ASTM G65 standard, which is 5 times higher than the resistance of the alloys used for the manufacture of gas turbine parts.

Similar content being viewed by others

References

O. O. Kuznechik, E. G. Grigor’ev, and A. V. Sosnovskii, Modeling and implementation of electrocontact welding deposition of powders of self-fluxing alloys, J. Eng. Phys. Thermophys., 94, No. 4, 995–1007 (2021).

Pierre L. Fauchais, Joachim V. R. Heberlein, and Maher I. Boulos, Thermal Spray Fundamentals. From Powder to Part, Springer, New York (2014).

V. M. Fomin, A. A. Golyshev, V. F. Kosarev, A. G. Malikov, A. M. Orishich, N. S. Ryashin, A. A. Filippov, and V. S. Shikalov, Creation of heterogeneous materials based on powders B4C and Ni by cold gas-dynamical spraying followed by layer-by-layer laser action, Prikl. Mekh. Tekh. Fiz., No. 5, 218–227 (2017).

A. K. Rebrov, I. S. Batraev, T. T. B’yadovskii, E. V. Gladkikh, A. S. Useinov, and M. N. Khomyakov, Gas jet deposition of diamond on a steel surface coated with a layer of WC–Co or Mo, Prikl. Mekh. Tekh. Fiz., No. 6, 118–129 (2019).

R. M. Poorman, H. B. Sargent, and H. Lamprey, Method and Apparatus Utilizing Detonation Waves for Spraying and Other Purposes, US Patent No. 2714553, August 2, 1955.

A. I. Zverev, S. Yu, Sharivker, and E. A. Astakhov, Detonation Spraying of Coatings [in Russian], Sudostroenie, Leningrad (1979).

S. S. Bartenev, Yu. R. Fed’ko, and A. I. Grigorov, Detonation Coatings in Mechanical Engineering [in Russian], Mashinostroenie, Leningrad (1982).

V. Ulianitsky, A. Shtertser, S. Zlobin, and I. Smurov, Computer-controlled detonation spraying: From process fundamentals toward advanced applications, J. Therm. Spray Technol., 20, 791–801 (2011).

D. A. Aleksandrov and N. I. Artemenko, Wear-resistant coatings for projection friction parts of modern gas turbine engines, Tr. VIAM: Élektron. Nauch. Tekh. Zh., No. 10, 6 (2016).

A. A. Shtertser, V. Yu. Ul’yanitskii, and D. K. Rybin, Suspension detonation spraying of ceramic coatings, Fiz. Goren. Vzryva, No. 4, 121–128 (2019).

A. A. Vasil’ev and V. A. Vasil’ev, Multifuel combustible mixtures: synthesis gas (CO–H2), J. Eng. Phys. Thermophys., 94, No. 3, 765–774 (2021).

V. Yu. Ul′yanitskii, A. A. Shtertser, and I. S. Batraev, Investigation of detonation of gaseous fuel based on metylacetylene and allene, Fiz. Goren. Vzryva, 51, No. 2, 118–124 (2015).

B. J. Gill, Super D-Gun, Aircraft Eng. Aerospace Technol., 62, Issue 8, 10-33 (1990).

V. Ulianitsky, I. Batraev, D. Dudina, and I. Smurov, Enhancing the properties of WC/Co detonation coatings using two-component fuels, Surf. Coat. Technol., 318, 244–249 (2017).

Coating Applications for Gas Turbine Engines. Praxair Surface Technologies; https://www.praxairsurfacetechnologies.com

V. Yu. Ul’yanitskii, A new generation of equipment for detonation spaying, Uproch. Tekhnol. Pokryt., No. 10, 36–41 (2013).

T. Gavrilenko, V. Grigoriev, S. Zhdan, Yu. Nikolaev, V. Boiko, and A. Papyrin, Acceleration of solid particles by gaseous detonation products, Combust. Flame, 66, Issue 2, 121-128 (1986).

T. P. Gavrilenko and Yu. A. Nikolaev, Calculation of the process of detonation-gas spaying, Fiz. Goren. Vzryva, 43, No. 6, 112-120 (2007).

T. Gavrilenko, Yu. Nikolaev., V. Ulianitsky, M. Kim, and H. Hong, Computational code for detonation spraying process, thermal spray, in: C. Coddet (Ed.), Meeting the challenges of the 21st century, May 25-29, 1998, Nice, France, ASM International (1998), pp. 1475-1483.

M. Guagliano, Relating Almen intensity to residual stresses induced by shot peening: A numerical approach, J. Mater. Proc. Technol., 110, 277–286 (2001).

W. Tillmann, L. Hagen, and W. Luo, Process parameter settings and their effect on residual stresses in WC/W2C reinforced iron-based arc sprayed coatings, Coatings, 7, No. 8, 125 (2017).

T. P. Gavrilenko, S. B. Zlobin, Yu. A. Nikolaev, and V. Yu. Ul’yanitskii, About the pin method of measurement of the strength of bonding thermal coatings, Uproch. Tekhnol. Pokryt., 32, No. 8, 54-56 (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Inzhenerno-Fizicheskii Zhurnal, Vol. 95, No. 7, pp. 1725–1735, November–December, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Batraev, I.S., Ivanyuk, K.V., Rybin, D.K. et al. Wear-Resistant Detonation Coatings Based on Chromium Carbide for Gas Turbines. J Eng Phys Thermophy 95, 1677–1687 (2022). https://doi.org/10.1007/s10891-022-02637-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10891-022-02637-1