Various methods of drying spicy-aromatic raw materials are described. The kinetic laws governing the process of convective drying of the ginger and galangal roots have been established. The stadial regimes of dehydration, in accordance with which the temperature of the drying agent in the first stage of the process is maintained at a level of 60°C and in the second at 45°C are substantiated and developed scientifically. The established regimes make it possible to reduce the expenditures of heat in drying and ensure the most complete preservation of the natural components of the starting material. A mathematical model of heat and mass transfer, phase transformations, and shrinkage is proposed, which can be used to establish dehydration regimes. The calculation of the total duration of the process of drying by V. V. Krasnikov’s method is presented.

Similar content being viewed by others

References

Yan-Qing Zhou, Hui Liu, Mu-Xue He, Ruibing Wang, Qing-Qian Zeng, Ying Wang, Wen-Cai Ye, and Qing-Wen Zhang, A review of the botany, phytochemical, and pharmacological properties of galangal, in: Handbook of Food Bioengineering, Natural and Artificial Flavoring Agents and Food Dyes, Academic Press (2018), pp. 351–396; ISBN 9780128115183; https://doi.org/10.1016/B978-0-12-811518-3.00011-9.

P. N. Ravindran, G. S. Pillai, I. Balachandran, and M. Divakaran, Galangal, in: Woodhead Publishing Series in Food Science, Technology and Nutrition, Handbook of Herbs and Spices, Woodhead Publishing (2012), pp. 303–318; ISBN 9780857090409; https://doi.org/10.1533/9780857095688.303.

K. V. Rubanka, V. A. Terlets’ka, and A. G. Abramova, Study of the quality of the dry extraction of ginger roots, in: Progressive Technique and Technology of Food Production in Restaurants and Trading Organizations [in Ukrainian], Issue 2 (26), KhDUKhT, Khar’kov (2017), pp. 301–310; https://doi.org/10.5281/zenodo.1108625.

O. Ya. Mezenova and L. A. Minkoilova, Development of the technology of concentrated base of beverages on the basis of vegetable raw materials, Vestn. Nauki Obraz. Sev.-Zapada Rossii, 4, No. 2, 1–10 (2018).

I. I. Bykov, D. V. Kompantsev, and I. M. Privalov, Extraction of biologically active substances from Zingiber officinale roscoe in the technology of phitopreparations (review), Vestn. Smolensk. Gos. Medits. Akad., 16, No. 2, 170–180 (2017).

Amaal Nasr, Antioxidant Properties of Oven and Microwave Dried Ginger (Zingiberofficinale), Thesis for: Master of Science, Advisor: Wong Chen Wai (2020); https://doi.org/10.13140/RG.2.2.34247.73123.

P. C. Onyenekwe and Hashimoto Seiji, The composition of the essential oil of dried Nigerian ginger (Zingiber officinale Roscoe), Eur. Food Res. Technol., 209, Issue 6, 407–410 (1999); https://doi.org/10.1007/s002170050517.

Galangal Root in the Carpathians [Electronic resource]; URL: http://karpatyua.org.ua/koren-kalgana-v-karpatax.htm (date of applying 02.02.21).

E. Jayashree, R. Visvanathan, and John T. Zachariah, Quality of dry ginger (Zingiber officinale) by different drying methods, J. Food Sci. Technol., 51, No. 11, 3190–3198 (2014); https://doi.org/10.1007/s13197-012-0823-8.

S. Phoungchandang, S. Nongsang, and P. Sanchai, The development of ginger drying using tray drying, heat pump-dehumidified drying, and mixed-mode solar drying, Dry. Technol., 27, No. 10, 1123–1131 (2009); https://doi.org/10.1080/07373930903221424.

Lin Xiaohui, Xu Jun-Li, and Sun Da-Wen, Evaluating drying feature differences between ginger slices and splits during microwave-vacuum drying by hyperspectral imaging technique, Food Chem., 332, Article ID 127407 (2020); ISSN 0308-8146; https://doi.org/10.1016/j.foodchem.2020.127407.

M. N. A. Hawlader, Conrad O. Perera, and Tian Min, Comparison of the retention of 6-gingerol in drying of ginger under modified atmosphere heat pump drying and other drying methods, Dry. Technol., 24, No. 1, 51–56 (2006); https://doi.org/10.1080/07373930500538675.

M. Hoque, B. Bala, M. Hossain, and M. Uddin, Drying kinetics of ginger rhizome (Zingiber officinale), Bangladesh J. Agric. Res., 38, No. 2, 301–319 (2013); https://doi.org/10.3329/bjar.v38i2.15892.

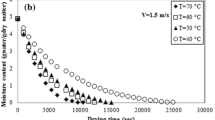

Namkanisorn Apinan and Murathathunyaluk Siripan, Sustainable drying of galangal through combination of low relative humidity, temperature and air velocity, Energy Rep., 6, Issue 2, 748–753 (2020); ISSN 2352-4847; https://doi.org/10.1016/j.egyr.2019.11.150.

Yu. F. Snezhkin and R. A. Shapar, Heat and Mass Transfer Technologies for Processing Pectine-Containing Raw Materials. Monograph [in Ukrainian], Inst. Tekhn. Teplofi z., NAN Ukrainy, Kiev, SIK GRUP, Ukraine (2018).

A. V. Luikov, Drying Theory [in Russian], 2nd. rev. and enlarged edn., Énergiya, Moscow (1968).

S. P. Rudobashta, The current state and directions of development of the theory and practice of drying, Collect. Sci. Works, Modern Energy Saving Thermal Technologies (Drying and Thermal Processes): 7th Int. Sci.-Pract. Conf. Dedicated to the 110th Anniversary of Academician A. V. Luikov, OOO “Megapolis,” Moscow (2020), pp. 13–22.

R. O. Shapar and N. M. Sorokova, Ways of energy and resource saving in drying thermolabile materials, in: Energy Efficiency in the 21st Century: Papers presented at the 20th Int. Pract. Conf., May 15–16, 2019, Interservis, Kiev (2019), pp. 249–253.

O. Husarova, R. Shapar, and N. Sorokova, Intensification of heat and mass transfer during the convective drying of apple to low final moisture, in: Theoretical and Practical Aspects of the Development of the European Research Area, Publishing House “Baltija Publishing”, Riga, Latvia (2020), pp. 191–211; https://doi.org/10.30525/978-9934-588-53-2-52.

V. N. Gulyaev (Ed.), Dried Vegetables and Fruits [in Russian], Pishchevaya Promyshlennost’, Moscow (1980).

P. V. Akulich, A. V. Temruk, and A. V. Akulich, Modeling and experimental investigation of the heat and moisture transfer in the process of microwave-convective drying of vegetable materials, J. Eng. Phys. Thermophys., 85, No. 5, 1034–1042 (2012).

S. P. Rudobashta, É. M. Kartashov, and G. A. Zueva, Mathematical modeling of the process of convective drying of materials taking into account their shrinkage, J. Eng. Phys. Thermophys., 93, No. 6, 1394–1401 (2020).

Sukmawaty, Guyup Mahardian Dwi Putra, Diah Ajeng Setiawati, Hary Kurniawan, and Ignatia Early Prasetyaning Reinhart, The application of mathematical model drying of galangal (Alpiniagalanga L.) using hybrid dryer equipment with rotary type of rack, Proc. 2nd Int. Conf. on Bioscience, Biotechnology, and Biometric, 23 December 2019, pp. 1–7 (2019); https://doi.org/10.1063/1.5141284.

A. Artnaseaw, S. Theerakulpisut, and C. Benjapiyaporn, Thin layer modeling of Tom Yum herbs in vacuum heat pump dryer, Food Sci. Technol. Int., 16, No. 2, 135–146 (2010); https://doi.org/10.1177/1082013209353090.

N. I. Nikitenko, Yu. F. Snezhkin, and N. N. Sorokovaya, Mathematical simulation of heat and mass transfer, phase conversions, and shrinkage for optimization of the process of drying of thermolabile materials, J. Eng. Phys. Thermophys., 78, No. 1, 75–89 (2005).

N. N. Sorokovaya, Modeling of Heat and Mass Transfer on Dehydration of Porous Bodies for Optimizing the Process of Drying, Author’s Abstract of Candidate’s Dissertation (in Engineering), ITTF NAN Ukrainy, Kiev (2004).

B. K. May, A. J. Sinclair, A. L. Halmos, and V. N. Tran, Quantitative analysis of drying behavior of fruits and vegetables, Drying, B, 1100–1107 (1998).

Yu. F. Snezhkin, O. V. Gusarova, and R. O. Shapar, Intensification of moisture removal during dehydration of fluid and vegetable raw materials, Trudy ONAKhT, 81, No. 1, 90–93 (2017).

V. V. Krasnikov, Conductive Drying [in Russian], Énergiya, Moscow (1973).

Author information

Authors and Affiliations

Corresponding author

Additional information

R. A. Shapar’ is deceased.

Translated from Inzhenerno-Fizicheskii Zhurnal, Vol. 95, No. 6, pp. 1390–1397, November–December, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Snezhkin, Y.F., Shapar’, R.A. & Gusarova, E.V. Theoretical and Experimental Studies of Convective Dehydration of Spicy-Aromatic Raw Materials. J Eng Phys Thermophy 95, 1366–1373 (2022). https://doi.org/10.1007/s10891-022-02605-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10891-022-02605-9