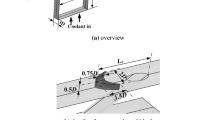

Recent studies reveal that an internal coolant crossflow plays an important role in the flow field and film cooling performance in the near-hole region. In the present paper a single array of cylindrical holes with crescent-shaped blocks downstream is considered. The cooling performance under the quiescent coolant plenum conditions with a perpendicular coolant crossflow are studied numerically at the blowing ratios 0.5–2.5. The height-to-diameter ratio of the crescent-shaped block varies from 0.25 to 1.0 with an interval of 0.25. Based on the numerical results, it may be deduced that a perpendicular crossflow induces an asymmetric pair of in-hole vortices and a biased coolant coverage on the surface downstream of the hole exit. However, the bias direction depends on the value of the blowing ratio. Compared with the quiescent plenum case, the perpendicular crossflow reduces the cooling performance, and the benefits result from the crescent-shaped block downstream.

Similar content being viewed by others

References

R. S. Bunker, Evolution of turbine cooling, Proc. ASME, Paper GT2017–63205 (2017).

B. T. An, J. J. Liu, C. Zhang, and S. J. Zhou, Film cooling of cylindrical hole with downstream short crescent-shaped block, J. Heat Transf., 135, No. 3, Article ID 031702 (2013).

A. Khorsi, A. Guelailia, and M. K. Hamidou, Improvement of fi lm cooling effectiveness with a small downstream block body, J. Appl. Mech. Tech. Phys., 57, No. 4, 666–671 (2016).

C. Zhang and Z. Wang, Effect of the downstream crescent-shaped block height on the flat-plate film flow and cooling performance, J. Appl. Mech. Tech. Phys., 59, No. 5, 951–961 (2018).

W. W. Zhou and H. Hu, A novel sand-dune-inspired design for improved film cooling performance, Int. J. Heat Mass Transf., 110, 908–920 (2017).

C. Zhang and Z. Wang, Influence of streamwise position of crescent-shaped block on flat-plate film cooling characteristics, J. Braz. Soc. Mech. Sci. Eng., 41, No. 11, Article ID 499 (2019).

K. Fatima, B. Khadidja, G. Mustapha, and A. Abbes, The effect of an upstream dune-shaped shells on forward and backward injection hole fi lm cooling, J. Heat Transf., 142, No. 12, Article ID 122302 (2020).

A. A. Khalatov, N. A. Panchenko, and T. V. Donil, Film cooling with a plate-length-distributed supply of the cooling agent into hemispherical depressions in rotation, J. Eng. Phys. Thermophys., 93, No. 6, 459–465 (2020).

A. Khalatov, E. Shi-Ju, D. Y. Wang, and I. Borisov, Film cooling evaluation of a single array of triangular craters, Int. J. Heat Mass Transf., 159, Article ID 120055 (2020).

M. Gritsch, A. Schulz, and S. Wittig, Eff ect of crossflows on the discharge coefficient of film cooling holes with varying angles of inclination and orientation, J. Turbomach., 123, No. 4, 781–787 (2001).

M. Gritsch, A. Schulz, and S. Wittig, Eff ect of internal coolant crossflow on the effectiveness of shaped fi lm-cooling holes, J. Turbomach., 125, No. 3, 547–554 (2003).

J. W. McClintic, J. B. Anderson, D. G. Bogard, T. E. Dyson, and Z. D. Webster, Effect of internal crossflow velocity on film cooling effectiveness – Part I: Compound angle shaped holes, J. Turbomach., 140, No. 1, Article ID 011004 (2018).

G. Wilfert and S. Wollf, Influence of internal flow on flow cooling effectiveness, J. Turbomach., 122, No. 2, 327–333 (2000).

C. K. Stimpson, J. C. Snyder, K. A. Thole, and D. Mongillo, Eff ects of coolant feed direction on additively manufactured film cooling holes, J. Turbomach., 140, No. 1, Article ID 111001 (2018).

Z. Y. Chen, Z. Zhang, Y. F. Li, X. R. Su, and X. Yuan, Vortex dynamics based analysis of internal crossflow effect on film cooling performance, Int. J. Heat Mass Transf., 145, Article ID 118757 (2019).

S. Acharya and D. H. Leedom, Large eddy simulations of discrete hole fi lm cooling with plenum inflow orientation effects, J. Heat Transf., 135, No. 1, Article ID 011010 (2013).

J. W. McClintic, S. R. Klavetter, J. R. Winka, J. B. Anderson, D. G. Bogard, and J. E. Dees, The effect of internal crossfl ow on the adiabatic eff ectiveness of compound angle fi lm cooling holes, J. Turbomach., 137, No. 7, Article ID 071006 (2014).

M. Frass, T. Glasenapp, A. Schulz, and H. Bauer, Film cooling measurements for a laidback fan-shaped hole: Effect of coolant crossflow on cooling effectiveness and heat transfer, J. Turbomach., 141, No. 4, Article ID 041006 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Inzhenerno-Fizicheskii Zhurnal, Vol. 95, No. 3, pp. 614–622, May–June, 2022.

Rights and permissions

About this article

Cite this article

Zhang, C., Zhang, P.F. & Ju, P.F. Film Cooling for a Cylindrical Hole with Downstream Crescent-Shaped Block with Perpendicular Crossflow. J Eng Phys Thermophy 95, 599–607 (2022). https://doi.org/10.1007/s10891-022-02516-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10891-022-02516-9