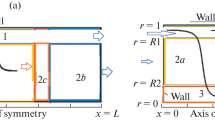

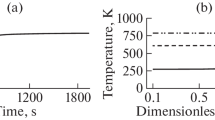

This paper considers a catalyst granule with a porous ceramic chemically inert base and active point centers, at which an exothermic reaction of synthesis takes place. The rate of a chemical reaction depends on temperature by the Arrhenius law. The heat is removed from the catalyst granule surface to the synthesis products by heat transfer. Based on the idea of self-consistent field, a closed system of equations is constructed for calculating the temperatures of the active centers. As an example, a catalyst granule of the Fischer–Tropsch synthesis with active metallic cobalt particles is considered. The stationary temperatures of the active centers are calculated by the timedependent technique by solving a system of ordinary differential equations. The temperature distribution inside the granule has been found for the local centers located on one diameter of the granule and distributed randomly in the granule’s volume. The existence of the critical temperature inside the reactor has been established, the excess of which leads to substantial superheating of local centers. The temperature distribution with local reaction centers differs qualitatively from the granule temperature calculated in the homogeneous approximation. The results of calculations are given.

Similar content being viewed by others

References

G. Antonioni, A. Dal Pozzo, D. Guglielmi, A. Tugnoli, and V. Cozzani, Enhanced modelling of heterogeneous gas-solid reactions in acid gas removal dry processes, Chem. Eng. Sci., 148, 140–154 (2016).

A. Benedetti and M. Strumendo, Application of a random pore model with distributed pore closure to the carbonation reaction, Chem. Eng. Trans., 43, 1153–1158 (2015).

P. Bhanja and A. Bhaumik, Porous nanomaterials as green catalyst for the conversion of biomass to bioenergy, Fuel, 185, 432–441 (2016).

S. K. Bhatia and D. D. Perlmutter, Unified treatment of structural effects in fluid–solid reactions, AIChE J., 29, 281–288 (1983).

J. Blamey, M. Zhao, V. Manovic, E. J. Anthony, D. R. Dugwell, and P. S. Fennell, A shrinking core model for steam hydration of CaO-based sorbents cycled for CO2 capture, Chem. Eng. J., 291, 298–305 (2016).

A. A. Ebrahimi, H. A. Ebrahim, M. Hatam, and E. Jamshidi, Finite element solution of the fluid–solid reaction equations with structural changes, Chem. Eng. J., 148, Nos. 2–3, 533–538 (2009).

H. F. H. Fei, S. H. S. Hu, J. X. J. Xiang, L. S. L. Sun, A. Z. A. Zhang, P. F. P. Fu, B. W. Ben Wang, and C. G. Chen, Modified random pore model study on coal char reactions under O2/CO2 atmosphere, Power Energy Eng. Conf. (APPEEC), 2010 Asia-Pacific (2010), No. 1, pp. 10–13.

R. J. Ferrier, L. Cai, Q. Lin, G. J. Gorman, and S. J. Neethling, Models for apparent reaction kinetics in heap leaching: A new semi-empirical approach and its comparison to shrinking core and other particle-scale models, Hydrometallurgy, 166, 22–33 (2016).

A. P. Jivkov, C. Hollis, F. Etiese, S. A. McDonald, and P. J. Withers, A novel architecture for pore network modelling with applications to permeability of porous media, J. Hydrol., 486, 246–258 (2013).

H. Li, M. Ye, and Z. Liu, A multi-region model for reaction-diffusion process within a porous catalyst pellet, Chem. Eng. Sci., 147, 1–12 (2016).

G. Marban, Modelling gasification reactions including the percolation phenomena, Chem. Eng. Sci., 49, No. 22, 3813–3821 (1994).

P. S. Grinchuk, Combustion of heterogeneous systems with a stochastic spatial structure near the propagation limits, J. Eng. Phys. Thermophys., 86, No. 4, 875–887 (2013).

L. Wei, Y. Zhao, Y. Zhang, C. Liu, J. Hong, H. Xiong, and J. Li, Fischer–Tropsch synthesis over a 3D foamed MCF silica support: Toward a more open porous network of cobalt catalysts, J. Catal., 340, 205–218 (2016).

J. Yang, V. Frøseth, D. Chen, and A. Holmen, Particle size effect for cobalt Fischer−Tropsch catalysts based on in situ CO chemisorption, Surf. Sci., 648, 317−321 (2016).

Y. Ohtsuka, T. Arai, S. Takasaki, and N. Tsubouchi, Fischer−Tropsch synthesis with cobalt catalysts supported on mesoporous silica for efficient production of diesel fuel fraction, Energy Fuels, 17, No. 4, 804–809 (2003).

W. Ma, G. Jacobs, D. E. Sparks, M. K. Gnanamani, V. R. R. Pendyala, C. H. Yen, J. L. S. Klettlinger, T. M. Tomsik, and B. H. Davis, Fischer−Tropsch synthesis: Support and cobalt cluster size effects on kinetics over Co/Al2O3 and Co/SiO2 catalysts, Fuel, 90, No. 2, 756–765 (2011).

M. Bartolini, J. Molina, J. Alvarez, M. Goldwasser, P. Pereira Almao, and M. J. P. Zurita, Effect of the porous structure of the support on hydrocarbon distribution in the Fischer–Tropsch reaction, J. Power Sources, 285, 1–11 (2015).

S. V. Pikulin, A property of solutions of equations that model some chemical reactions, Mat. Modelir., 27, No. 7, 97–102 (2015).

A. N. Subbotin, B. S. Gudkov, and V. I. Yakerson, Phenomenon of temperature hysteresis in heterogeneous catalysis, Izv. Akad. Nauk, Ser. Khim., No. 8, 1379–1385 (2000).

V. S. Ermolaev, K. O. Gryaznov, E. B. Mitberg, V. Z. Mordkovich, and V. F. Tretyakov, Laboratory and pilot plant fixedbed reactors for Fischer–Tropsch synthesis: Mathematical modeling and experimental investigation, Chem. Eng. Sci., 138, 1–8 (2015).

A. A. Samarskii and E. S. Nikolaev, Methods of Solution of Grid Equations [in Russian], Nauka, Мoscow (1978).

G. I. Marchuk, Methods of Computational Mathematics [in Russian], Nauka, Мoscow (1980).

B. E. Poling, J. M. Prausnitz, and J. P. O’Connell, The Properties of Gases and Liquids, 5th edn., McGraw-Hill Companies, New York (2004).

A. G. Shashkov, A. F. Zolotukhina, and L.P. Fokin, Generalization and calculation of the thermal diffusion factor of binary hydrogen-containing gaseous mixtures, J. Eng. Phys. Thermophys., 84, No. 1, 39–48 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Inzhenerno-Fizicheskii Zhurnal, Vol. 91, No. 1, pp. 46–57, January–February, 2018.

Rights and permissions

About this article

Cite this article

Derevich, I.V., Fokina, A.Y. Mathematical Model of Heat Transfer in the Catalyst Granule with Point Reaction Centers. J Eng Phys Thermophy 91, 40–51 (2018). https://doi.org/10.1007/s10891-018-1717-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10891-018-1717-z