Abstract

Within the framework of the mechanics of heterophase systems a mathematical model for the process of pressing wood has been offered; this model takes account of the influence of its complex rheological properties and surface phenomena in thin interlayers of water on the change in a porous structure. With numerical methods, a study has been made of the influence of the sample’s humidity and temperature fields on the strength and quality of the material obtained.

Similar content being viewed by others

References

R. I. Nigmatulin, Principles of the Mechanics of Heterogeneous Media [in Russian], Nauka, Moscow (1978).

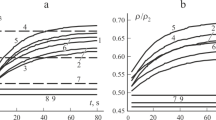

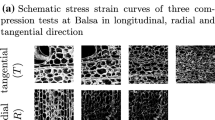

O. R. Dornyak, Modeling of the rheological behavior of wood in compression processes, Inzh.-Fiz. Zh., 76, No. 3, 150–155 (2003).

Yu. A. Buevich, Structural-mechanical properties and filtration in elastic cracked-porous material, Inzh.-Fiz. Zh., 46, No. 4, 593–600 (1984).

B. V. Deryagin and N. V. Churaev, Properties and kinetics of moisture in porous bodies, in: Water in Disperse Systems [in Russian], Khimiya, Moscow (1989), pp. 7–31.

I. E. Dzyaloshinskii, E. M. Lifshits, and L. P. Pitaevskii, General theory of Van der Waals forces, Usp. Fiz. Nauk, 73, No. 3, 381–422 (1961).

B. V. Deryagin, N. A. Krotova, and V. P. Smilga, Adhesion of Solids [in Russian], Nauka, Moscow (1973).

P. N. Khukhryanskii, Pressing of Wood [in Russian], Lesnaya Promyshlennost’, Moscow (1964).

A. Hanhijärvi, Deformation properties of Finnish spruce and pine wood in tangential and radial directions in association to high-temperature drying. Part II. Experimental results under constant conditions (viscoelastic creep), Holz als Roh-und Werkstoff, 57, 365–372 (1999).

B. N. Ugolev, Wood Science with the Principles of Merchandizing [in Russian], Lesnaya Promyshlennost’, Moscow (1986).

B. I. Ogarkov and A. V. Apostol, The Theory and Physical Essence of Wood Pressing [in Russian], Izd. VGU, Voronezh (1981).

P. S. Kuts and N. N. Grinchik, Transfer equations in capillary-porous media for problems in nonisothermal drying, sorption, and two-phase filtration, Inzh.-Fiz. Zh., 49, No. 1, 110–116 (1985).

E. K. Ashkenazi, Anisotropy of Wood and Wood Materials [in Russian], Lesnaya Promyshlennost’, Moscow (1978).

Author information

Authors and Affiliations

Additional information

__________

Translated from Inzhenerno-Fizicheskii Zhurnal, Vol. 78, No. 5, pp. 62–69, September–October, 2005.

Rights and permissions

About this article

Cite this article

Dornyak, O.R. Mathematical modeling of the process compaction of wood. J Eng Phys Thermophys 78, 899–906 (2005). https://doi.org/10.1007/s10891-006-0010-8

Received:

Issue Date:

DOI: https://doi.org/10.1007/s10891-006-0010-8