Abstract

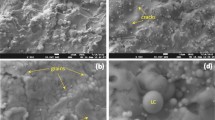

In the present study, a novel durable three layered thermal barrier coating (TBCs) were prepared using atmospheric plasma spray (APS) on Ni718 superalloy substrate consisting of the YSZ nano-clusters. In order to develop a functionally graded coating system, the non-transformable (t′) tetragonal YSZ nano-clusters (40 nm) were synthesized by a sol–gel process and characterized at the temperature 1200 °C for 100 h. NiCrAlY was used as bond coat. The developed coating system introduces a protective top layer of MoSi2 (top coat) for preventing diffusion of oxygen, oxidation of the bond coating, provides thermal insulation and protection against corrosion and high temperature erosion. Microstructural, thermal oxidation resistance, thermal shock and adhesion strength of TBCs were analyzed. Different properties of as-sprayed TBCs have no significant effect on thermal oxidation property. The TBCs have shown better thermal shock resistance but lower adhesion strength than the TBCs made of without MoSi2 layer.

Similar content being viewed by others

References

H. Reymann, MCrAlY Deposition by HVOF: A Suitable Alternative to LPPS. Turbine Forum: Advanced Coatings for High Temperatures (Nice Port St. Laurent, 2002), pp. 17–19.

K. Vaidyanathan, E. H. Jordan, and M. Gell (2004). Acta Mater. 52, 1107.

J. A. Thompson and T. W. Clyne (2001). Acta Mater. 49, 1565.

K. W. Schlichting, N. P. Padture, E. H. Jordan, and M. Gell (2003). Mater. Sci. Eng. A 342, 120.

M. P. Boyce Gas Turbine Engineering Handbook, 2nd ed (Gulf Professional Publishing, Houston, 2002).

R. L. Jones, R. F. Reidy, and D. Mess (1996). Surf. Coat. Technol. 82, 70.

N. P. Padture and H. E. Jordan (2002). Science 296, 280.

R. W. Trice, Y. J. Su, J. R. Mawdsley, and K. T. Faber (2002). J. Mater. Sci. 37, 2359.

R. Sivakumar and B. L. Mordike (1989). Surf. Coat. Technol. 37, 139.

C. S. Richard, G. Beranger, J. Lu, and J. F. Flavenot (1996). Surf. Coat. Technol. 82, 99.

A. Kulkarni, H. Herman, F. Decarlo, and R. Subramanian (2004). Metall. Mater. Trans. A. 35, 1945.

H. X. Deng, H. J. Shi, H. C. Yu, and B. Zhong (2011). Surf. Coat. Technol. 205, 3621.

A. González, E. López, A. Tamayo, E. Restrepo, and F. Hernández (2010). DYNA 77, 151.

M. Hetmanczyk, L. Swadzba, and B. Mendala (2007). J. Achiev. Mater. Manuf. Eng. 24, 1.

R. C. Reed The Superalloys: Fundamentals and Applications (Cambridge University Press, Cambridge, 2006).

M. R. Winter and D. R. Clarke (2006). Acta Mater. 54, 5051.

J. Ilavsky, J. K. Stalick, and J. Wallace (2001). J. Therm. Spray Technol. 10, 497.

J. A. Krogstad, M. Lepple, Y. Gao, D. M. Lipkin, and C. G. Levi (2011). J. Am. Ceram. Soc. 94, 4548.

J. T. Demasi-Marcin and D. K. Gupta (1994). Surf. Coat. Technol. 68, 1.

T. Sourmail, Coatings for high temperature applications, University of Cambridge, 2004. Available: http://Thomas-sourmail.net/coatings/index.html. [date 30 October 2012].

L. Seadzba, et al. (1993). Surf. Coat. Technol. 62, 486.

W. Beele, G. Marijnissen, and A. V. Lieshout (1999). Surf. Coat. Technol. 120–121, 61.

H. Xu and H. Guo Thermal Barrier Coatings (Woodhead Publishing Limited, Sawston, 2011).

T. Kato, K. Ogawa, and T. Shoji (2002). J. Jpn. Therm. Spray. Soc. 39, 1.

D. Seo, K. Ogawa, M. Tanno, T. Shoji, and S. Murata (2007). Surf. Coat. Technol. 201, 7952.

A. Manap, A. Nakano, and K. Ogawa (2012). J. Therm. Spray Technol. 21, 586.

K. Ogawa, K. Ito, T. Shoji, D. W. Seo, H. Tezuka, and H. Kato (2006). J. Therm. Spray Technol. 15, 640.

J. Y. Byun, J. K. Yoon, G. H. Kim, J. S. Kim, and C. S. Choi (2002). Scr. Mater. 46, 537.

K. Sonoya and S. Tobe (2009). J. Solid Mech. Mater. Eng. 3, 1127.

S. Tailor, M. Singh, and A. V. Doub (2016). J. Clust. Sci. In press.

M. Pechini (1967). Patent No. 3,330,697. United States Patent Office.

K. Singh, L. Pathak, and S. Roy (2007). Ceram. Int. 33, 1463.

S. Sakka Handbook of Sol–Gel Science and Technology. 1. Sol–Gel Processing, vol. 1 (Springer, New York, 2005).

Y.-W. Zhang, Z.-G. Yan, F.-H. Liao, C.-S. Liao, and C.-H. Yan (2004). Mater. Res. Bull. 39, 1763.

A. Naumenko, N. Berezovska, M. Biliy, and O. Shevchenko (2008). Phys. Chem. Solid State 9, 121.

J. Ilavsky, A. J. Allen, G. G. Long, et al. (1997). J. Am. Ceram. Soc. 80, 733.

G. Bolelli, K. Sabriruddin, L. Lusvarghi, et al. (2010). Surf. Coat. Technol. 205, 363.

T. Nakamura, G. Qian, and C. C. Berndt (2000). J. Am. Ceram. Soc. 83, 578.

Acknowledgments

The authors gratefully acknowledge the financial support of the Ministry of Education and Science of the Russian Federation in the framework of Increase Competitiveness Program of NUST «MISiS» (Grant № К4-2014-081) and experimental support of National University of Science and Technology “MISiS”, Moscow, Russia and Council of Scientific and Industrial Research, CSIR-HQS, Rafi Marg, New Delhi-110001, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tailor, S., Singh, M., Mohanty, R.M. et al. Microstructural and Thermal properties of Plasma Sprayed YSZ Nano-Clusters Thermal Barrier Coatings. J Clust Sci 27, 1501–1518 (2016). https://doi.org/10.1007/s10876-016-1025-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10876-016-1025-8