Abstract

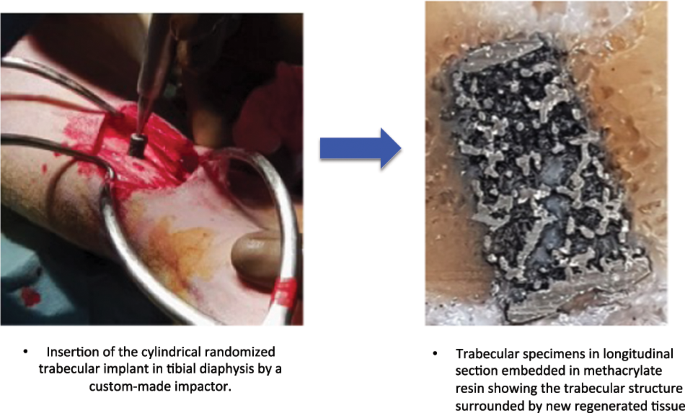

The additive manufacturing techniques (AM) are able to realize three-dimensional trabecular structures that mimic the trabecular structure of the bone. An in vivo study in sheep was carried out with the aim of assessing the bone response and the trend of osteointegration of a randomized trabecular titanium structure produced by the AM technique. In 6 sheep were implanted 84 specimens with a trabecular titanium structure (4 implants in the femur distal epiphysis; 4 implants in the tibial plate; 6 implants in the tibial shaft). Sheep were sacrificed at 3 postoperative time-points: 6 weeks, 10 weeks, 14 weeks. Histomorphometric analysis was performed for the evaluation of Bone Implant Contact, and Bone Ingrowth. A standard push-out test was used to analyze the mechanical characteristics of the bone-implant interface. The histomorphometric data and biomechanical tests showed a fast osseointegration of the specimens both in the cancellous and in the cortical bone. The quantitative analysis of osseointegration data in cancellous bone showed the percentage of the surface of the implant in direct contact with the regenerated bone matrix significantly improved from 28% at 6 weeks to 54% at 14 weeks. An early osseointegration occurred in cortical bone showing that 75% of surface of implant was in direct contact with regenerated bone after 6 weeks; this value increased to 85% after 14 weeks. Mechanical tests revealed an early improvement of mean peak load of implants at 10 weeks (4486 N ± 528 N) compared to values at 6 weeks (2516 N ± 910 N) confirming the high rate of progression of osseointegration in the cortical bone. The non-mineralized matrix followed an increasing process of mineralization almost completely after 14 weeks. The results of this study have showed a rapid osseointegration and excellent biocompatibility for a randomized trabecular titanium structure that should be confirmed by clinical investigations.

Similar content being viewed by others

References

Katz JN, Earp BE, Gomoll AH. Surgical management of osteoarthritis. Arthritis Care Res (Hoboken). 2010;62:1220–8.

Goodman SB, Gómez Barrena E, Takagi M, Konttinen YT. Biocompatibility of total joint replacements: a review. J Biomed Mater Res A. 2009;90:603–18.

Lee K, Goodman SB. Current state and future of joint replacements in the hip and knee. Expert Rev Med Dev. 2008;5:383–93.

Albrektsson T, Johansson C. Osteoinduction, osteoconduction and osseointegration. Eur Spine J. 2001;10:S96–101.

Schatzker J. Osseointegration of metal. Can J Surg. 1995;38:S49–54.

Karageorgiou V, Kaplan D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials. 2005;26:5474–91.

Cheng A, Humayun A, Cohen DJ, et al. Additively manufactured 3D porous Ti-6Al-4V constructs mimic trabecular bone structure and regulate osteoblast proliferation, differentiation and local factor production in a porosity and surface roughness dependent manner. Biofabrication. 2014;6:045007.

Zhang Z, Yuan L, Lee PD, et al. Modeling of time dependent localized flow shear stress and its impact on cellular growth within additive manufactured titanium implants. J Biomed Mater Res B Appl Biomater. 2014;102:1689–99.

Zhang Z, Jones D, Yue S, et al. Hierarchical tailoring of strut architecture to control permeability of additive manufactured titanium implants. Mater Sci Eng C Mater Biol Appl. 2013;33:4055–62.

Horn TJ, Harrysson OL. Overview of current additive manufacturing technologies and selected applications. Sci Prog. 2012;95:255–82.

Basalah A, Shanjani Y, Esmaeili S, Toyserkani E. Characterizations of additive manufactured porous titanium implants. J Biomed Mater Res B Appl Biomater. 2012;100:1970–9.

Ferenc J-S, Neda Z. On the size distribution of Poisson Voronoi cells. Phys A. 2007;385:518–26.

Pineda E, Bruna P, Crespo D. Cell size distribution in random tessellations of space. Phys Rev E Stat Nonlin Soft Matter Phys. 2004;70:066119.

Gómez S, Vlad MD, López J, Fernández E. Design and properties of 3D scaffolds for bone tissue engineering. Acta Biomater. 2016;42:341–50.

Bertollo N, Matsubara M, Shinoda T, et al. Effect of surgical fit on integration of cancellous bone and implant cortical bone shear strength for a porous titanium. J Arthroplast. 2011;26:1000–7.

Svehla M, Morberg P, Bruce W, et al. The effect of substrate roughness and hydroxyapatite coating thickness on implant shear strength. J Arthroplast. 2002;17:304–11.

Dellavia C, Carmagnola D, Storelli S, et al. Histological evaluation of the peri-implant tissues of three human-retrieved Straumann implants. J Investig Clin Dent. 2011;2:216–20.

Varoni E, Canciani E, Palazzo B, et al. Effect of Poly-L-Lysine coating on titanium osseointegration: from characterization to in vivo studies. J Oral Implantol. 2015;41:626–31.

Fabbro MD, Taschieri S, Canciani E, et al. Osseointegration of titanium implants with different rough surfaces: a histologic and histomorphometric study in an adult minipig model. Implant Dent. 2017;26:357–66.

Chen D, Bertollo N, Lau A, et al. Osseointegration of porous titanium implants with and without electrochemically deposited DCPD coating in an ovine model. J Orthop Surg Res. 2011;6:56.

Bertollo N, Sandrini E, Dalla Pria P, Walsh WR. Osseointegration of multiphase anodic spark deposition treated porous titanium implants in an ovine model. J Arthroplast. 2015;30:484–8.

Dhert WJ, Verheyen CC, Braak LH, et al. A finite element analysis of the push-out test: influence of test conditions. J Biomed Mater Res. 1992;26:119–30.

Hunt RJ. Percent agreement, Pearson’s correlation, and kappa as measures of inter-examiner reliability. J Dent Res. 1986;65:128–30.

Warnke PH, Douglas T, Wollny P, et al. Rapid prototyping: porous titanium alloy scaffolds produced by selective laser melting for bone tissue engineering. Tissue Eng Part C Methods. 2009;15:115–24.

Frazier WE. Metal additive manufacturing: a review. J Mater Eng Perform. 2014;23:1917–28.

Wang H, Eliaz N, Xiang Z, et al. Early bone apposition in vivo on plasma-sprayed and electrochemically deposited hydroxyapatite coatings on titanium alloy. Biomaterials. 2006;27:4192–203.

Perticarini L, Zanon G, Rossi SM, Benazzo FM. Clinical and radiographic outcomes of a trabecular titanium™ acetabular component in hip arthroplasty: results at minimum 5 years follow-up. BMC Musculoskelet Disord. 2015;16:375.

Steno B, Kokavec M, Necas L. Acetabular revision arthroplasty using trabecular titanium implants. Int Orthop. 2015;39:389–95.

Bistolfi A, Ravera L, Graziano E, et al. A Trabecular Titanium™ cup for total hip arthroplasty: a preliminary clinical and radiographic report. Minerva Ortopedica e Traumatologica. 2014;65:199–205.

Pearce AI, Richards RG, Milz S, et al. Animal models for implant biomaterial research in bone: a review. Eur Cell Mater. 2007;13:1–10.

Willie BM, Bloebaum RD, Bireley WR, et al. Determining relevance of a weight-bearing ovine model for bone ingrowth assessment. J Biomed Mater Res A. 2004;69:567–76.

Sing SL, An J, Yeong WY, Wiria FE. Laser and electron-beam powder-bed additive manufacturing of metallic implants: a review on processes, materials and designs. J Orthop Res. 2016;34:369–85.

Biemond JE, Hannink G, Verdonschot N, et al. The effect of E-beam engineered surface structures on attachment, proliferation and differentiation of human mesenchymal stem cells. Biomed Mater Eng. 2011;21:271–9.

de Wild M, Schumacher R, Mayer K, et al. Bone regeneration by the osteoconductivity of porous titanium implants manufactured by selective laser melting: a histological and micro computed tomography study in the rabbit. Tissue Eng. 2013;19:2645–54.

Cohen DJ, Cheng A, Sahingur K, et al. Performance of laser sintered Ti-6Al-4V implants with bone-inspired porosity and micro/nanoscale surface roughness in the rabbit femur. Biomed Mater. 2017;12:025021.

Taniguchi N, Fujibayashi S, Takemoto M, et al. Effect of pore size on bone ingrowth into porous titanium implants fabricated by additive manufacturing: an in vivo experiment. Mater Sci Eng C Mater Biol Appl. 2016;59:690–701.

Carmagnola D, Botticelli D, Canciani E, et al. Histologic and immunohistochemical description of early healing at marginal defects around implants. Int J Periodontics Restor Dent. 2014;34:e50–7.

Canullo L, Wiel Marin G, Tallarico M, et al. Histological and Histomorphometrical evaluation of postextractive sites grafted with mg-enriched nano-hydroxyapatite: a randomized controlled trial comparing 4 versus 12 months of healing. Clin Implant Dent Relat Res. 2016;18:973–83.

Arrigoni E, de Girolamo L, Di Giancamillo A, et al. Adipose-derived stem cells and rabbit bone regeneration: histomorphometric, immunohistochemical and mechanical characterization. J Orthop Sci. 2013;18:331–9.

Author contributions

VR and MA contributed conception and design of the study; MO, LP, MMvD performed surgical intervention and animals care, EC and CD performed histological evaluation and analysis of data, DA performed biomechanical tests and analysis of data, VR and EC wrote the draft of the manuscript, CD and RD revised critically data interpretation. All authors contributed to manuscript revision, read and approved the submitted version.

Funding

This animal study was funded by Permedica that supported the University of Turin for the veterinary surgery, cares, post-surgical radiological and clinical examination of the animals and the University of Milan for histological analysis and biomechanical tests of the harvested specimens.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

VR and MA are employees of Permedica S.p.A. These authors did not have a role in the in analysis and interpretation of the data. They had no possibility to influence or to change the results of this study. The other authors, their immediate families, and any research foundation with which they are affiliated have not received any financial payments or other benefits from any commercial entity related to the subject of this article.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ragone, V., Canciani, E., Arosio, M. et al. In vivo osseointegration of a randomized trabecular titanium structure obtained by an additive manufacturing technique. J Mater Sci: Mater Med 31, 17 (2020). https://doi.org/10.1007/s10856-019-6357-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-019-6357-0