Abstracts

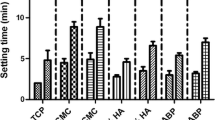

The inferior anti-washout property of injectable calcium phosphate cement (CPC) limits its wider application in clinic. In this study, the improvement of anti-washout performance of CPC by addition of konjac glucomannan or guar gum, which was dissolved in the CPC liquid, was first studied. The influence of KGM/GG blend with different mass ratios on the anti-washout property, compressive strength and in vitro cytocompatibility of CPC was estimated. The results revealed that small amount of KGM or GG could obviously enhance the anti-washout property of CPC. Moreover, the washout resistance efficiency of KGM/GG blend was better than KGM or GG alone. The addition of KGM/GG blend slightly shortened the final setting time of CPC. Although the introduction of KGM/GG blend reduced the compressive strength of CPC, the compressive strength still reached or surpassed that of human cancellous bone. The best KGM/GG mass ratio was 5:5, which was most efficient at not only reducing CPC disintegration, but also increasing compressive strength. The addition of KGM/GG blend obviously promoted the cells proliferation on the CPC. In short, the CPC modified by KGM/GG blend exhibited excellent anti-washout property, appropriate setting time, adequate compressive strength, and good cytocompatibility, and has the potential to be used in bone defect repair.

The addition of KGM/GG blend significantly improved the anti-washout property of CPC. The best KGM/GG mass ratio was 5:5, which was most efficient in reducing the CPC disintegration.

Similar content being viewed by others

References

Brown WE, Chow LC. A new calcium phosphate, water-setting cement. Cements research progress. Wester Westerville, OH: American Ceramic Society; 1986. pp. 352–79.

Fernández E, Gil FJ, Ginebra MP, Driessens FCM, Planell JA, Best SM. Calcium phosphate bone cements for clinical applications, Part I. Solution chemistry. J Mater Sci Mater Med. 1999;10:169–76.

Fernández E, Gil FJ, Ginebra MP, Driessens FCM, Planell JA, Best SM. Calcium phosphate bone cements for clinical applications. Part II: Precipitate formation during setting reactions. J Mater Sci Mater Med. 1999;10:177–83.

Wang XH, Ma JB, Wang YN, He BL. Bone repair in radii and tibias of rabbits with phosphorylated chitosan reinforced calcium phosphate cements. Biomaterials. 2002;23:4167–76.

Guo DG, Xu KW, Zhao XY, Han Y. Development of a strontium-containing hydroxyapatite bone cement. Biomaterials. 2005;26:4073–83.

Wang XP, Ye JD, Wang YJ, Wu XP, Bai B. Control of crystallinity of hydrated products in a calcium phosphate bone cement. J Biomed Mater Res Part A. 2007;81A:781–90.

Qi XP, Ye JD, Wang YJ. Improved injectability and in vitro degradation of a calcium phosphate cement containing poly(lactide-co-glycolide) microspheres. Acta Biomater. 2008;4:1837–45.

Li XM, He FP, Ye JD. Preparation, characterization and in vitro cell performance of anti-washout calcium phosphate cement modified by sodium polyacrylate. RSC Adv. 2017;7:32842–49.

Wang XP, Chen L, Xiang H, Ye JD. Influence of anti-washout agents on the rheological properties and injectability of a calcium phosphate cement. J Biomed Mater Res Part B Appl Biomater. 2007;81B:410–8.

Liu JQ, Li JY, Ye JD, He FP. Setting behavior, mechanical property and biocompatibility of anti-washout wollastonite/calcium phosphate composite cement. Ceram Int. 2016;42:13670–81.

Liu JQ, Li JY, Ye JD. Properties and cytocompatibility of anti-washout calcium phosphate cement by introducing locust bean gum. J Mater Sci Technol. 2016;32:1021–6.

Chen FP, Song ZY, Liu CS. Fast setting and anti-washout injectable calcium–magnesium phosphate cement for minimally invasive treatment of bone defects. J Mater Chem B. 2015;3:9173–81.

Cherng A, Takagi S, Chow LC. Effects of hydroxypropyl methylcellulose and other gelling agents on the handling properties of calcium phosphate cement. J Biomed Mater Res. 1995;35:273–7.

Ishikawa K, Miyamoto Y, Kon M, Nagayama M, Asaoka K. Non-decay type fast-setting calcium phosphate cement: composite with sodium alginate. Biomaterials. 1995;16:527–32.

El-Fiqi A, Kim JH, Perez RA, Kim HW. Novel bioactive nanocomposite cement formulations with potential properties: incorporation of the nanoparticle form of mesoporous bioactive glass into calcium phosphate cements. J Mater Chem B. 2015;7:1321–34.

Huang L, Takahashi R, Kobayashi S, Kawase T, Nishinari K. Gelation behavior of native and acetylated konjac glucomannan. Biomacromolecules. 2002;3:1296–303.

Yoshimura M, Takaya T, Nishinari K. Rheological studies on mixtures of corn starch and konjac-glucomannan. Carbohyd Polym. 1997;35:71–9.

Nishinari K, Williams PA, Phillips GO. Review of the physico-chemical characteristics and properties of konjac mannan. Food Hydrocoll. 1992;6:199–222.

Maekaji K. Determination of acidic component of konjac mannan. Agric Biol Chem. 1978;42:177–8.

Zhang FS, Shen YD, Ren T, Wang L, Su Y. Synthesis of 2-alkenyl-3-butoxypropyl guar gum with enhanced rheological properties. Int J Biol Macromol. 2017;97:317–22.

Vijayendran BR, Bone T. Absolute molecular weight and molecular weight distribution of guar by size exclusion chromatography and low-angle laser light scattering. Carbohyd Polym. 1984;4:299–313.

Wang XP, Ye JD, Wang YJ. Hydration mechanism of a novel PCCP + DCPA cement system. J Mater Sci Mater Med. 2008;19:813–16.

Kokubo T, Takadama H. How useful is SBF in predicting in vivo bone bioactivity. Biomaterials. 2006;27:2907–15.

Barralet JE, Gaunt T, Wright AJ, Gibson IR, Knowles JC. Effect of porosity reduction by compaction on compressive strength and microstructure of calcium phosphate cement. J Biomed Mater Res. 2001;63:1–9.

Bose S, Darsell J, Kintner M, Hosick H, Bandyopadhyay A. Pore size and pore volume effects on alumina and TCP ceramic scaffolds. Mat Sci Eng C-Mater. 2003;23:479–86.

Chen ZT, Ni SY, Han SG, Crawford R, Lu S, Wei F, Chang J, Wu CT, Xiao Y. Nanoporous microstructures mediate osteogenesis by modulating the osteo-immune response of macrophages. Nanoscale. 2017;9:706–18.

Langer R, Tirrell DA. Designing materials for biology and medicine. Nature. 2004;428:487–92.

Lotz JC, Gehart TN, Hayes WC. Mechanical properties of trabecular bone from the proximal femur: a quantitative CT study. J Comput Assist Tomogr. 1990;14:107–14.

Nie HR, Shen XX, Zhou ZH, Jiang QS, Chen YW, Xie A, Wang Y, Han CC. Electrospinning and characterization of konjac glucomannan/chitosan nanofibrous scaffolds favoring the growth of bone mesenchymal stem cells. Carbohyd Polym. 2011;85:681–6.

Kundu S, Das A, Basu A, Ghosh D, Datta P, Mukherjee A. Carboxymethyl guar gum synthesis in homogeneous phase and macroporous 3D scaffolds design for tissue engineering. Carbohyd Polym. 2018;191:71–8.

Tiwari A, Grailer JJ, Pilla S, Steeber DA, Gong SQ. Biodegradable hydrogels based on novel photopolymerizable guar gum–methacrylate macromonomers for in situ fabrication of tissue engineering scaffolds. Acta Biomater. 2009;5:441–3452.

Acknowledgements

This research was supported by the National Natural Science Foundation of China under Grant No. 51672087, the Science and Technology Program of Guangzhou City of China under Grant No. 201508020017, and the Fundamental Research Funds for the Central Universities. The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Qian, G., Li, X., He, F. et al. Improvement of anti-washout property of calcium phosphate cement by addition of konjac glucomannan and guar gum. J Mater Sci: Mater Med 29, 183 (2018). https://doi.org/10.1007/s10856-018-6193-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-018-6193-7