Abstract

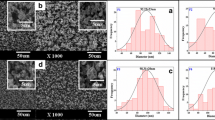

Polyurethane (PU) and doxorubicine loaded-PU nanofiber mats were prepared by the electrospinning technique. The effect of some system and process parameters including flow rate, distance from collector, and concentration of solution on the size and morphology of nanofibers was investigated. The size, morphology and drug content of nanofiber mats were followed by scanning electron microscopy (SEM). FTIR and TGA methods were used for structural and thermal characterization, and DSC was also used for determining the form of drug within nanofiber mat. Doxorubicine release kinetics were studied in two different pHs (4.5 and 7.5) for two drug content and it was observed that there is an inverse correlation between the amounts of drug loaded and released.

Similar content being viewed by others

References

Liang D, Hsiao BS, Chu B. Functional electrospun nanofibrous scaffolds for biomedical applications. Adv Drug Deliv. 2007;59:1392–412.

Lee KB, Yoon KR, Woo SI, Choi IS. Surface modification of poly(glycolic acid) (PGA) for biomedical applications. J Pharm Sci. 2003;92:933–7.

Tyler B, Gullotti D, Mangraviti A, Utusuki T, Brem H. Polylactic acid (PLA) controlled delivery carriers for biomedical applications. Adv Drug Deliv Rev. 2016;107:163–75.

Suwantong O. Biomedical applications of electrospun polycaprolactone fiber mats. Polym Adv Tech. 2016;27:1264–73.

Burke A, Hasırcı N. Polyurethanes in biomedical applications. In: Hasırcı N, Hasırcı V, editors. Advances in experimental medicine and biology. Boston, MA: Springer; 2004. Vol. 553.

Wan W, Bannerman AD, Yang L, Mak H. Poly(vinyl alcohol) cryogels for biomedical applications. In: Okay O, editor. Polymeric cryogels. Boston, MA: Springer; 2014.

Kim J, Choi SY, Kim KM, Lee CH, Park HS, Hwang SS, Hong SM, Kwak S, Yoo HO. Synthesis of PEO-based materials for biomedical applications. Macromol Symp. 2006;245-6:565–70.

Devine DM, Devery SM, Lyons JG, Geever LM, Kennedy JE, Higginbotham CL. Multifunctional polyvinylpyrrolidinone-polyacrylic acid copolymer hydrogels for biomedical applications. Int J Pharm. 2006;326:50–9.

Yang TH. Recent applications of polyacrylamide as biomaterials. Recent Pat Mater Sci. 2008;1:29–40.

Boland ED, Coleman BD, Barnes CP, Simpson DG, Wnek GE, Bowlin GL. Electrospinning polydioxanone for biomedical applications. Acta Biomater. 2005;1:115–23.

Andrianov AK (ed.). Polyphosphazenes for biomedical applications. John Wiley & Sons; 2009.

Engels HW, Pirkl HG, Albers R, Albach RW, Krause J, Hoffmann A, Casselmann H, Dormish J. Polyurethanes: versatile materials and sustainable problem solvers for today’s challenges. Angew Chem Int Ed. 2013;52:9422–41.

Rockwood DN, Woodhouse KA, Fromstein JD, Chase DB, Rabolt JF. Characterization of biodegradable polyurethane microfibers for tissue engineering. J Biomater Sci. 2007;18:743–58.

Zdrahala RJ, Zdrahala IJ. Biomedical applications of polyurethanes: a review of past promises, present realities, and a vibrant future. J Biomater Appl. 1999;14:67–90.

Sheikh FA, Barakat NAM, Kanjwal MA, Chaudhari AA, Jung IH, Lee JH, Kim HY. Electrospun antimicrobial polyurethane nanofibers containing silver nanoparticles for biotechnological applications. Macromol Res. 2009;17:688–96.

Lionelli GT, Lawrence WT. Wound dressing. Surg Clin North Am. 2003;83:617–38.

Thomas S. Wound management and dressings. Pharm P. 1990;1:37–57.

Bhardwaj N, Kundu SC. Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv. 2010;28:325–47.

Khil MS, Cha DI, Kim HY, Kim IS, Bhattarai N. Electrospun nanofibrous poly-urethane membrane as wound dressing. J Biomed Mater Res B. 2003;67:675–9.

Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol. 2003;63:2223–53.

Verreck G, Chun I, Peeters J, Rosenblatt J, Brewster ME. Preparation and characterization of nanofibers containing amorphous drug dispersions generated by electrostatic spinning. Pharm Res. 2003;20:810–7.

Thompson CJ, Chase GG, Yarin AL, Reneker DH. Effects of parameters on nanofiber diameter determined from electrospinning model. Polymer. 2007;48:6913–22.

Yuan X, Zhang Y, Dong C, Sheng J. Morphology of ultrafine polysulfone fibers prepared by electrospinning. Polym Int. 2004;53:1704–10.

Haghi AK, Akbari M. Trends in electrospinning of natural nanofibers. Phys Status Solid A. 2007;204:1830–4.

Megelski S, Stephens JS, Chase DB, Rabolt JF. Micro- and nanostructured surface morphology on electrospun polymer fibers. Macromolecules. 2002;35:8456–66.

Zong X, Kim K, Fang D, Ran S, Hsiao BS, Chu B. Structure and process relationship of electrospun bioadsorbable nanofiber membrane. Polymer. 2002;439:4403–12.

Doshi J, Reneker DH. Electrospinning process and application of electrospun fibers. J Electro. 1995;35:151–6.

Geng X, Kwon OH, Jang J. Electrospinning of chitosan dissolved in concentrated acetic acid solution. Biomaterials. 2005;26:5427–32.

Lee JS, Choi KH, Ghim HD, Kim SS, Chun DH, Kim HY. Role of molecular weight of atactic poly (vinyl alcohol) (PVA) in the structure and properties of PVA nanofabric prepared by electrospinning. J Appl Polym Sci. 2004;93:1638–46.

Trovati GT, Sanches EA, Neto SC, Mascarenhas YP, Chierice GO. Characterization of poly-urethane resins by FTIR, TGA, and XRD. J Appl Polym Sci. 2010;115:263–8.

Manocha B, Margaritis A. Controlled release of doxorubicin from doxorubicin/γ-polyglutamic acid ionic complex. J Nanomater. 2010; Article ID 780171:1–9.

Teicher BA. Cancer drug resistance. Totowa, NJ: Humana Press Inc.; 2006.

Yu H, Jia Y, Yao C, Lu Y. PCL/PEG core/sheath fibers with controlled drug release rate fabricated on the basis of a novel combined technique. Int J Pharm. 2014;469:17–22.

Acknowledgements

This study was carried out in accordance with the Chemistry Department, Hacettepe University (Ankara, Turkey). The support of the HU Scientific Research Foundation through the HU-BAB-011D10601001 and HU-BAB-012D06601014 projects are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Kiliç, E., Yakar, A. & Pekel Bayramgil, N. Preparation of electrospun polyurethane nanofiber mats for the release of doxorubicine . J Mater Sci: Mater Med 29, 8 (2018). https://doi.org/10.1007/s10856-017-6013-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-017-6013-5