Abstract

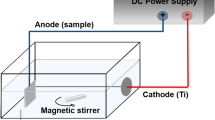

Deposition of nanostructured and low-wear zirconia (ZrO2) thin films on the metallic component of a total joint implant is envisaged to reduce wear of the soft ultra-high molecular weight polyethylene (UHMWPE) counterpart. In this work, morphological surface features, wear resistance and in vitro-biocompatibility of zirconia thin films deposited by the novel Pulsed Plasma Deposition (PPD) method have been investigated. Film thickness, roughness and wettability were found to be strongly dependent on deposition gas pressure. Interestingly, wear rate of UHMWPE disks coupled to zirconia-coated titanium spheres was only poorly correlated to the contact angle values, while film roughness and thickness seemed not to affect it. Furthermore, wear of UHMWPE, when coupled with zirconia coated-titanium spheres, significantly decreased with respect to uncoated spheres under dry or NaCl-lubricated conditions; besides, when using bovine serum, similar results were obtained for coated and uncoated spheres. Finally, suitable mesenchymal stem and osteoblast cells adhesion, proliferation and viability were observed, suggesting good biocompatibility of the nanostructured zirconia films. Taken together, the results shown in this work indicate that zirconia thin films deposited by the PPD method deserve further investigations as low-wear materials for biomedical applications such as total joint replacement.

Similar content being viewed by others

References

Dalmiglio M, Schaaff P, Holzwarth U, Chiesa R, Rondelli G. The effect of surface treatments on the fretting behavior of Ti–6Al–4 V alloy. J Biomed Mater Res A. 2008;86B:407–16.

Dong H, Shi W, Bell T. Potential of improving tribological performance of UHMWPE by engineering the Ti6Al4 V counterfaces. Wear. 1999;225–229:146–53.

Rautray TR, Narayanan R, Kim K. Ion implantation of titanium based biomaterials. Prog Mater Sci. 2011;56:1137–77.

Wu H, Zhang X, He X, Li M, Huang XB, Hang RQ, Tang B. Wear and corrosion resistance of anti-bacterial Ti–Cu–N coatings on titanium implants. Appl Surf Sci. 2014;316:614–21.

Piconi C, Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials. 1999;20:1–25.

Kaluđerović MR, Schreckenbach JP, Hans-Ludwig Graf H. Zirconia coated titanium for implants and their interactions with osteoblast cells. Mater Sci Eng C 2014;44:254–61.

Dong H, Yang G, Cai H, Ding H, Li C, Li C. The influence of temperature gradient across ZIRCONIA on thermal cyclic lifetime of plasma-sprayed thermal barrier coatings. Ceram Int. 2015;41:11046–56.

Torres-Huerta AM, Dominguez-Crespo MA, Onofre-Bustamante E, Flores-Vela A. Characterization of ZrO2 thin films deposited by MOCVD as ceramic coatings. J Mater Sci. 2012;47:2300–9.

Catauro M, Bollino F, Papale F. Biocompatibility improvement of titanium implants by coating with hybrid materials synthesized by sol–gel technique. J Biomed Mater Res A. 2014;102:4473–9.

Hidalgo H, Reguzina E, Millon E, Thomann AL, Mathias J, Boulmer-Leborgne C, Sauvage T, Brault P. Yttria-stabilized zirconia thin films deposited by pulsed-laser deposition and magnetron sputtering. Surf Coat Technol. 2011;205:4495–9.

Sprio S, Guicciardi S, Bellosi A, Pezzotti G. Yttria-stabilized zirconia films grown by radiofrequency magnetron sputtering: Structure, properties and residual stresses. Surf Coat Technol. 2006;200:4579–85.

Huang YW, Li GF, Feng JH, Zhang Q. Investigation on structural, electrical and optical properties of tungsten-doped tin oxide thin films. Thin Solid Films. 2010;518:1892–6.

Dediu V, Hueso LE, Bergenti I, Riminucci A, Borgatti F, Graziosi P, Newby C, Casoli F, De Jong MP, Taliani C, Zhan Y. Room-temperature spintronic effects in Alq3-based hybrid devices. Phys Rev B. 2008;78:115203.

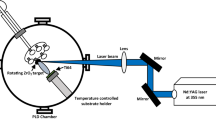

Boi M, Bianchi M, Gambardella A, Liscio F, Kaciulis S, Visani A, Barbalinardo M, Valle F, Iafisco M, Lungaro L, Milita S, Cavallini M, Marcacci M, Russo A. Tough and adhesive nanostructured calcium phosphate thin films deposited by the pulsed plasma deposition method. Rsc Adv. 2015;5:78561–71.

Bianchi M, Russo A, Taliani C, Marcacci M. Pulsed plasma deposition (PPD) technique, dekker encyclopedia of nanoscience and nanotechnology, 3rd edn. CRC Press; 2015. doi:10.1081/E-Enn3-120053233.

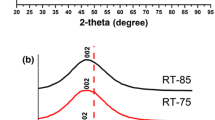

Bianchi M, Russo A, Lopomo N, Boi M, Maltarello MC, Sprio S, Baracchi M, Marcacci M. Pulsed plasma deposition of zirconia thin films on UHMWPE: proof of concept of a novel approach for joint prosthetic implants. J Mater Chem B. 2013;1:310–8.

Bianchi M, Boi M, Lopomo N, Maltarello MC, Liscio F, Milita S, Visani A, Russo A, Marcacci M. Nanomechanical characterization of zirconia thin films deposited on UHMWPE by pulsed plasma deposition. J Mech Med Biol. 2015;15:1550070.

Bianchi M, Lopomo N, Boi M, Gambardella A, Marchiori G, Berni M, Pavan P, Marcacci M, Russo A. Ceramic thin films realized by means of pulsed plasma deposition technique: applications for orthopaedics. J Mech Med Biol. 2015;15:1540002.

Marchiori G, Lopomo N, Boi M, Berni M, Bianchi M, Gambardella A, Visani A, Russo A, Marcacci M. Optimizing thickness of ceramic coatings on plastic components for orthopaedic applications: a finite element analysis. Mat Sci Eng C. 2016;58:381–8.

Liu Y, Peterson DA, Kimura H, Schubert D. Mechanism of cellular 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT) reduction. J Neurochem. 1997;69:581–93.

Papadopoulos NG, Dedoussis GV, Spanakos G, Gritzapis AD, Baxevanis CN, Papamichail M. An improved fluorescence assay for the determination of lymphocyte-mediated cytotoxicity using flow cytometry. J Immunol Methods. 1994;177:101–11.

Faulstich H, Zobeley S, Rinnerthaler G, Small JV. Fluorescent phallotoxins as probes for filamentous actin. J Muscle Res Cell Motil. 1988;5:370–83.

Yarmolich D, Nozar P, Gleizer S, Krasik YE, Mittica G, Ancora C, Brillante A, Bilotti I, Taliani C. Characterization of deposited films and the electron beam generated in the pulsed plasma deposition gun. Jpn J Appl Phys. 2011;50:08JD03.

Gleizer S, Yarmolich D, Felsteiner J, Krasik YE, Nozar P, Taliani C. Electron beam and plasma modes of a channel spark discharge operation. J Appl Phys. 2009;106:073301.

Graziosi P, Prezioso M, Gambardella A, Kitts C, Rakshit RK, Riminucci A, Bergenti I, Borgatti F, Pernechele C, Solzic M, Pullini D, Busquets-Mataixa D, Dediu VA. Conditions for the growth of smooth La0.7Sr0.3MnO3 thin films by pulsed electron ablation. Thin Solid Films. 2013;534:83–9.

Wei J, Igarashi T, Okumori N, Igarashi T, Maetani T, Liu B, Yoshinari M. Influence of surface wettability on competitive protein adsorption and initial attachment of osteoblasts. Biomed Mater. 2009;4:045002.

Bianchi M, Urquia Edreira ER, Wolke JGC, Birganic ZT, Habibovic P, Jansen JA, Tampieri A, Marcacci M, Leeuwenburgh SCG, van den Beucken JJJP. Substrate geometry directs the in vitro mineralization of calcium phosphate ceramics. Acta Biomater 2014;10:661–9.

Petrov I, Barna PB, Hultman L, Greene JE. Microstructural evolution during film growth. J Vac Sci Technol, A. 2003;21:S117.

Herminghaus S. Roughness-induced non-wetting. Europhys Lett. 2000;52:165.

Att W, Takeuchi M, Suzuki T, Kubo K, Anpo M, Ogawa T. Enhanced osteoblast function on ultraviolet light-treated zirconia. Biomaterials. 2009;30:1273.

Escudeiro A, Wimmer MA, Polcar T, Cavaleiro A. Tribological behavior of uncoated and DLC-coated CoCr and Ti-alloys in contact with UHMWPE and PEEK counterbodies. Tribol Int. 2015;89:97–104.

Acknowledgments

The study was supported by the project “Nanostructured Coatings Enhancing Material Performances in Joint Arthroplasty” (project code: GR-2010-2312686), funded by the Italian Ministry of Health and co-funded by the Istituto Ortopedico Rizzoli. The authors would like to particularly thank Carmelo Carcasio for his support in mechanical manufacturing, Dr. Simone Sprio (Institute of Science and Technology for Ceramics, National Research Council of Italy) and Dr. Maria Cristina Maltarello (Laboratorio di Biologia Cellulare Muscoloscheletrica, Istituto Ortopedico Rizzoli) for providing the zirconia targets and the lubricants for the tribological tests, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bianchi, M., Gambardella, A., Berni, M. et al. Surface morphology, tribological properties and in vitro biocompatibility of nanostructured zirconia thin films. J Mater Sci: Mater Med 27, 96 (2016). https://doi.org/10.1007/s10856-016-5707-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-016-5707-4