Abstract

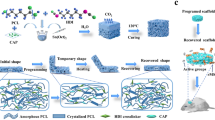

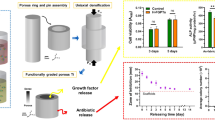

The employment of a tissue engineering scaffold able to release an antimicrobial agent with a controlled kinetics represents an effective tool for the treatment of infected tissue defects as well as for the prevention of scaffolds implantation-related infectious complications. This research activity was aimed at the development of additively manufactured star poly(ε-caprolactone) (*PCL) scaffolds loaded with levofloxacin, investigated as antimicrobial fluoroquinolone model. For this purpose a computer-aided wet-spinning technique allowing functionalizing the scaffold during the fabrication process was explored. Scaffolds with customized composition, microstructure and anatomical external shape were developed by optimizing the processing parameters. Morphological, thermal and mechanical characterization showed that drug loading did not compromise the fabrication process and the final performance of the scaffolds. The developed *PCL scaffolds showed a sustained in vitro release of the loaded antibiotic for 5 weeks. The proposed computer-aided wet-spinning technique appears well suited for the fabrication of anatomical scaffolds endowed with levofloxacin-releasing properties to be tested in vivo for the regeneration of long bone critical size defects in a rabbit model.

Similar content being viewed by others

References

Pritchard EM, Valentin T, Panilaitis B, Omenetto F, Kaplan DL. Antibiotic-releasing silk biomaterials for infection prevention and treatment. Adv Funct Mater. 2013;23:854–61.

Buranapanitkit B, Srinilta V, Ingviga N, Oungbho K, Geater A, Ovatlarnporn C. The efficacy of a hydroxyapatite composite as a biodegradable antibiotic delivery system. Clin Orthop Relat Res. 2004;424:244–52.

Wenke JC, Owens BD, Svoboda SJ, Brooks DE. Effectiveness of commercially-available antibiotic-impregnated implants. J Bone Joint Surg Br. 2006;88-B:1102–4.

Makinen TJ, Veiranto M, Lankinen P, Moritz N, Jalava J, Törmälä P, et al. In vitro and in vivo release of ciprofloxacin from osteoconductive bone defect filler. J Antimicrob Chemother. 2005;56:1063–8.

Ambrose CG, Clyburn TA, Louden K, Joseph J, Wright J, Gulati P, et al. Effective treatment of osteomyelitis with biodegradable microspheres in a rabbit model. Clin Orthop Relat Res. 2004;421:293–9.

Nair MB, Kretlow JD, Mikos AG, Kasper FK. Infection and tissue engineering in segmental bone defects—a mini review. Curr Opin Biotechnol. 2011;22:721–5.

Shah S, Kasper FK, Mikos A. Perspectives on the prevention and treatment of infection for orthopedic tissue engineering applications. Chin Sci Bull. 2013;58:4342–8.

Puppi D, Dinucci D, Bartoli C, Mota C, Migone C, Dini F, et al. Development of 3D wet-spun polymeric scaffolds loaded with antimicrobial agents for bone engineering. J Bioact Compatible Polym. 2011;26:478–92.

McLaren JS, White LJ, Fau-Cox HC, Fau-Ashraf W, Ashraf W, Fau-Rahman CV, Rahman CV, Fau-Blunn GW, Blunn GW, Fau-Goodship AE, et al. A biodegradable antibiotic-impregnated scaffold to prevent osteomyelitis in a contaminated in vivo bone defect model. Eur Cell Mater. 2014;27:332–49.

Silverman LD, Lukashova L, Herman OT, Lane JM, Boskey AL. Release of gentamicin from a tricalcium phosphate bone implant. J Orthop Res. 2007;25:23–9.

Xie Z, Liu X, Jia W, Zhang C, Huang W, Wang J. Treatment of osteomyelitis and repair of bone defect by degradable bioactive borate glass releasing vancomycin. J Control Release. 2009;139:118–26.

Puppi D, Zhang X, Yang L, Chiellini F, Sun X, Chiellini E. Nano/microfibrous polymeric constructs loaded with bioactive agents and designed for tissue engineering applications: a review. J Biomed Mater Res B. 2014;102:1562–79.

Mota C, Puppi D, Chiellini F, Chiellini E. Additive manufacturing techniques for the production of tissue engineering constructs. J Tissue Eng Regen Med. 2015;9:174–90.

Giannitelli SM, Mozetic P, Trombetta M, Rainer A. Combined additive manufacturing approaches in tissue engineering. Acta Biomater. 2015;24:1–11.

Chevalier E, Chulia D, Pouget C, Viana M. Fabrication of porous substrates: a review of processes using pore forming agents in the biomaterial field. J Pharm Sci. 2008;97:1135–54.

Yen H-J, Hsu S-H, Tseng C-S, Huang J-P, Tsai C-L. Fabrication of precision scaffolds using liquid-frozen deposition manufacturing for cartilage tissue engineering. Tissue Eng A. 2008;15:965–75.

Puppi D, Mota C, Gazzarri M, Dinucci D, Gloria A, Myrzabekova M, et al. Additive manufacturing of wet-spun polymeric scaffolds for bone tissue engineering. Biomed Microdev. 2012;14:1115–27.

Wu W, Wang W, Li J. Star polymers: advances in biomedical applications. Prog Polym Sci. 2015;46:55–85.

Balakrishnan S, Krishnan M, Dubois P, Narayan R. Kinetic and thermodynamic considerations in the synthesis of a new three-arm poly(ε-caprolactone). Polym Eng Sci. 2004;44:1491–7.

Balakrishnan S, Krishnan M, Narayan R, Dubois P. Three-arm poly (ε-caprolactone) by extrusion polymerization. Polym Eng Sci. 2006;46:235–40.

Puppi D, Detta N, Piras AM, Chiellini F, Clarke DA, Reilly GC, et al. Development of electrospun three-arm star poly(ε-caprolactone) meshes for tissue engineering application. Macromol Biosci. 2010;10:887–97.

Mota C, Puppi D, Gazzarri M, Bártolo P, Chiellini F. Melt electrospinning writing of three-dimensional star poly(ϵ-caprolactone) scaffolds. Polym Int. 2013;62:893–900.

Puppi D, Piras AM, Chiellini F, Chiellini E, Martins A, Leonor IB, et al. Optimized electro- and wet-spinning techniques for the production of polymeric fibrous scaffolds loaded with bisphosphonate and hydroxyapatite. J Tissue Eng Reg Med. 2011;5:253–63.

Mota C, Puppi D, Dinucci D, Gazzarri M, Chiellini F. Additive manufacturing of star poly(ε-caprolactone) wet-spun scaffolds for bone tissue engineering applications. J Bioact Compat Polym. 2013;28:320–40.

Dini F, Barsotti G, Puppi D, Coli A, Briganti A, Giannessi E, et al. Tailored star poly(ε-caprolactone) wet-spun scaffolds for in vivo regeneration of long bone critical size defects. J Bioact Compat Polym. 2016;31:15–30.

Rubinstein E. History of quinolones and their side effects. Chemotherapy. 2001;47(suppl 3):3–8.

Drilica K, Hooper DC. Mechanisms of quinolone action. In: Hooper DC, Rubinstein E, editors. Quinolone antimicrobial agents. 3rd ed. Washington, DC: American Society of Microbiology Press; 2003. p. 19–40.

Greenberg RN, Newman MT, Shariaty S, Pectol RW. Ciprofloxacin, lomefloxacin, or levofloxacin as treatment for chronic osteomyelitis. Antimicrob Agents Chemother. 2000;44:164–6.

Darley ESR, MacGowan AP. Antibiotic treatment of Gram-positive bone and joint infections. J Antimicrob Chemother. 2004;53:928–35.

Tuzlakoglu K, Alves CM, Mano JF, Reis RL. Production and characterization of chitosan fibers and 3-D fiber mesh scaffolds for tissue engineering applications. Macromol Biosci. 2004;4:811–9.

Tuzlakoglu K, Pashkuleva I, Rodrigues MT, Gomes ME, van Lenthe GH, Müller R, et al. A new route to produce starch-based fiber mesh scaffolds by wet spinning and subsequent surface modification as a way to improve cell attachment and proliferation. J Biomed Mater Res A. 2010;92A:369–77.

Pashkuleva I, López-Pérez PM, Azevedo HS, Reis RL. Highly porous and interconnected starch-based scaffolds: production, characterization and surface modification. Mater Sci Eng C. 2010;30:981–9.

Mathiowitz E, Lavin DM, Hopkins RA. Wet spun microfibers: potential in the design of controlled-release scaffolds? Ther Deliv. 2013;4:1075–7.

Hirano S, Zhang M, Nakagawa M. Release of glycosaminoglycans in physiological saline and water by wet-spun chitin–acid glycosaminoglycan fibers. J Biomed Mater Res. 2001;56:556–61.

Denkbas E, Seyyal M, Piskin E. Implantable 5-fluorouracil loaded chitosan scaffolds prepared by wet spinning. J Membrane Sci. 2000;172:33–8.

Ucar S, Yilgor P, Hasirci V, Hasirci N. Chitosan-based wet-spun scaffolds for bioactive agent delivery. J Appl Polym Sci. 2013;130:3759–69.

Nie HL, Ma ZH, Fan ZX, Branford-White CJ, Ning X, Zhu LM, et al. Polyacrylonitrile fibers efficiently loaded with tamoxifen citrate using wet-spinning from co-dissolving solution. Int J Pharm. 2009;373:4–9.

Rissanen M, Puolakka A, Ahola N, Tonry A, Rochev Y, Kellomäki M, et al. Effect of protein-loading on properties of wet-spun poly(L,D-lactide) multifilament fibers. J Appl Polym Sci. 2010;116:2174–80.

Gao H, Gu Y, Ping Q. The implantable 5-fluorouracil-loaded poly (l-lactic acid) fibers prepared by wet-spinning from suspension. J Control Release. 2007;118:325–32.

Jung M-R, Shim I-K, Kim E-S, Park Y-J, Yang Y-I, Lee S-K, et al. Controlled release of cell-permeable gene complex from poly(L-lactide) scaffold for enhanced stem cell tissue engineering. J Control Release. 2011;152:294–302.

Lavin DM, Stefani RM, Zhang L, Furtado S, Hopkins RA, Mathiowitz E. Multifunctional polymeric microfibers with prolonged drug delivery and structural support capabilities. Acta Biomater. 2012;8:1891–900.

Lavin DM, Zhang L, Furtado S, Hopkins RA, Mathiowitz E. Effects of protein molecular weight on the intrinsic material properties and release kinetics of wet spun polymeric microfiber delivery systems. Acta Biomater. 2013;9:4569–78.

Mulder M. Influence of various parameters on membrane morphology. In: Mulder M, editor. Basic principle of membrane technology. 2nd ed. Dordrecht: Kluwer Academic; 1996. p. 123–40.

Coombes AGA, Rizzi SC, Williamson M, Barralet JE, Downes S, Wallace WA. Precipitation casting of polycaprolactone for applications in tissue engineering and drug delivery. Biomaterials. 2004;25:315–25.

Mota C, Wang SY, Puppi D, Gazzarri M, Migone C, Chiellini F, et al. Additive manufacturing of poly[(R)-3-hydroxybutyrate-co-(R)-3-hydroxyhexanoate] scaffolds for engineered bone development. J Tissue Eng Regen Med. 2014;. doi:10.1002/term.1897.

Zein I, Hutmacher DW, Tan KC, Teoh SH. Fused deposition modeling of novel scaffold architectures for tissue engineering applications. Biomaterials. 2002;23:1169–85.

Shor L, Yildirim ED, Güçeri S, Sun W. Precision extruding deposition for freeform fabrication of PCL and PCL-HA tissue scaffolds. In: Narayan R, Boland T, Lee Y-S, editors. Printed biomaterials. New York: Biological and Medical Physics, Biomedical Engineering: Springer; 2010. p. 91–110.

Huang X, Brazel CS. On the importance and mechanisms of burst release in matrix-controlled drug delivery systems. J Control Release. 2001;73:121–36.

Zilberman M, Elsner JJ. Antibiotic-eluting medical devices for various applications. J Control Release. 2008;130:202–15.

Mouriño V, Boccaccini AR. Bone tissue engineering therapeutics: controlled drug delivery in three-dimensional scaffolds. J R Soc Interface. 2010;7:209–27.

Gristina AG. Biomaterial-centered infection: microbial adhesion versus tissue integration. Science. 1987;237:1588–95.

Hetrick EM, Schoenfisch MH. Reducing implant-related infections: active release strategies. Chem Soc Rev. 2006;35:780–9.

Acknowledgments

This study was supported by a Tuscany Region (Italy) funded Project “Nuovi Supporti Bioattivi a Matrice Polimerica per la Rigenerazione Ossea in Applicazioni Odontoiatriche (R.E.O.S.S.)” as part of the program POR CReO FESR 2007–2013 - Le ali alle tue idee. Authors are grateful to Mr. Piero Narducci for his precious support in recording SEM images.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Puppi, D., Piras, A.M., Pirosa, A. et al. Levofloxacin-loaded star poly(ε-caprolactone) scaffolds by additive manufacturing. J Mater Sci: Mater Med 27, 44 (2016). https://doi.org/10.1007/s10856-015-5658-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-015-5658-1