Abstract

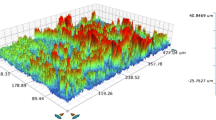

Titanium (Ti) and its alloys have been popularly used as implant biomaterial for decades. Recently, titanium–zirconium (TiZr) alloy has been developed as an alternative implant material with improved strength in load bearing areas. Surface modification is one of the key factors to alter the surface properties to hasten osseointegration. Spark anodic oxidation (anodization) is one such method that is reported to enhance the bone formation around implants. This study aims to anodize TiZr and study its surface characteristics and cytocompatibility by cell culture experiments using osteoblast-like cells. Titanium (Ti) and TiZr discs were anodized in an electrolyte containing dl-α-glycerophosphate and calcium acetate (CA) at 300 V. The surface characteristics were analyzed by scanning electron microscopy, electron dispersive spectroscopy, X-ray diffraction (XRD), atomic force microscopy and goniometry. Using osteoblast-like cells viability, proliferation, differentiation and mineralization was assessed. The anodized surfaces demonstrated increased oxygen, entrapped calcium and phosphorous from the electrolyte used. XRD analysis confirmed the presence of anatase in the oxide layer. Average roughness increased and there was a significant decrease in contact angle (P < 0.01) following anodization. The anodized TiZr (aTiZr) surfaces were more nano-porous compared to anodized Ti (aTi). No significant difference was found in the viability of cells, but after 24 h the total number of cells was significantly higher (P < 0.01). Proliferation, alkaline phosphatase activity and calcium deposits were significantly higher on anodized surfaces compared to machined surfaces (P < 0.05, ANOVA). Anodization of TiZr resulted in a more nanoporous and hydrophilic surface than aTi, and osteoblast biocompatibility appeared comparable to aTi.

Similar content being viewed by others

References

Kobayashi E, Matsumoto S, Yoneyama T, Hamanaka H. Mechanical properties of the binary titanium-zirconium alloys and their potential for biomedical materials. J Biomed Mater Res. 1995;29(8):943–50.

Gottlow J, Dard M, Kjellson F, Obrecht M, Sennerby L. Evaluation of a new titanium–zirconium dental implant: a biomechanical and histological comparative study in the mini pig. Clin Implant Dent Relat Res. 2012;14(4):538–45.

Barter S, Stone P, Bragger U. A pilot study to evaluate the success and survival rate of titanium–zirconium implants in partially edentulous patients: results after 24 months of follow-up. Clin Oral Implants Res. 2012;7(23):873–81.

Albrektsson T, Wennerberg A. Oral implant surfaces: part 1–review focusing on topographic and chemical properties of different surfaces and in vivo responses to them. Int J Prosthodont. 2004;17(5):536–43.

Sul Y-T, Johansson CB, Petronis S, Krozer A, Jeong Y, Wennerberg A, et al. Characteristics of the surface oxides on turned and electrochemically oxidized pure titanium implants up to dielectric breakdown: the oxide thickness, micropore configurations, surface roughness, crystal structure and chemical composition. Biomaterials. 2002;23(2):491–501.

Park IS, Lee MH, Bae TS, Seol KW. Effects of anodic oxidation parameters on a modified titanium surface. J Biomed Mater Res B. 2008;84(2):422–9.

Sul Y-T, Johansson CB, Jeong Y, Albrektsson T. The electrochemical oxide growth behaviour on titanium in acid and alkaline electrolytes. Med Eng Phys. 2001;23(5):329–46.

Bai Y, Park IS, Park HH, Lee MH, Bae TS, Duncan W, et al. The effect of annealing temperatures on surface properties, hydroxyapatite growth and cell behaviors of TiO2 nanotubes. Surf Interface Anal. 2011;43(6):998–1005.

Duncan W, Lee M, Dovban A, Hendra N, Ershadi S, Rumende H. Anodization increases early integration of Osstem implants in sheep femurs. Ann R Australas Coll Dent Surg. 2008;19:152–6.

Zhu X, Kim K-H, Jeong Y. Anodic oxide films containing Ca and P of titanium biomaterial. Biomaterials. 2001;22(16):2199–206.

Shibata Y, Kawai H, Yamamoto H, Igarashi T, Miyazaki T. Antibacterial titanium plate anodized by being discharged in NaCl solution exhibits cell compatibility. J Dent Res. 2004;83(2):115–9.

Sul Y-T, Johansson CB, Röser K, Albrektsson T. Qualitative and quantitative observations of bone tissue reactions to anodised implants. Biomaterials. 2002;23(8):1809–17.

Li L-H, Kong Y-M, Kim H-W, Kim Y-W, Kim H-E, Heo S-J, et al. Improved biological performance of Ti implants due to surface modification by micro-arc oxidation. Biomaterials. 2004;25(14):2867–75.

Ishizawa H, Ogino M. Formation and characterization of anodic titanium oxide films containing Ca and P. J Biomed Mater Res. 1995;29(1):65–72.

Balshi SF, Wolfinger GJ, Balshi TJ. Analysis of 164 titanium oxide-surface implants in completely edentulous arches for fixed prosthesis anchorage using the pterygomaxillary region. Int J Oral Maxillofac Implants. 2005;20(6):946–52.

Shibuya Y, Kobayashi M, Takeuchi J, Asai T, Murata M, Umeda M, et al. Analysis of 472 Branemark system TiUnite implants:a retrospective study. Kobe J Med Sci. 2009;55(3):E73–81.

Östman P-O, Hellman M, Sennerby L. Ten years later. Results from a prospective single-centre clinical study on 121 oxidized (TiUnite™) Brånemark implants in 46 patients. Clin Implant Dent Relat Res. 2012;14(6):852–60.

Ikarashi Y, Toyoda K, Kobayashi E, Doi H, Yoneyama T, Hamanaka H, Tsuchiya T. Improved biocompatibility of titanium–zirconium (Ti–Zr) alloy: tissue reaction and sensitization to Ti–Zr alloy compared with pure Ti and Zr in rat implantation study. Mater Trans. 2005;46(10):2260–7.

Chen X, Nouri A, Li Y, Lin J, Hodgson PD, Wen C. Effect of surface roughness of Ti, Zr, and TiZr on apatite precipitation from simulated body fluid. Biotechnol Bioeng. 2008;2(101):378–87.

Bernhard N, Berner S, De Wild M, Wieland M. The binary TiZr alloy—A newly developed Ti alloy for use in dental implants. Forum Implant. 2009;5:30–9.

Shui C, Scutt A. Mild heat shock induces proliferation, alkaline phosphatase activity, and mineralization in human bone marrow stromal cells and MG-63 cells in vitro. J Bone Miner Res. 2001;16(4):731–41.

Kurze P, Drysmann W, Knofler W. Anodic oxidation using spark discharge–a new surface treatment method for medical technology. Stomatol DDR. 1986;36(10):549–54.

Ishizawa H, Ogino M. Characterization of thin hydroxyapatite layers formed on anodic titanium oxide films containing Ca and P by hydrothermal treatment. J Biomed Mater Res. 1995;29(9):1071–9.

El-wassefy NA, Hammouda IM, Habib ANEdA, El-awady GY, Marzook HA. Assessment of anodized titanium implants bioactivity. Clin Oral Implant Res. 2014;25(2):e1–9.

Kuromoto NK, Simão RA, Soares GA. Titanium oxide films produced on commercially pure titanium by anodic oxidation with different voltages. Mater Charact. 2007;58(2):114–21.

Teh TH, Berkani A, Mato S, Skeldon P, Thompson GE, Habazaki H, et al. Initial stages of plasma electrolytic oxidation of titanium. Corros Sci. 2003;45(12):2757–68.

Sul YT, Johansson CB, Jeong Y, Roser K, Wennerberg A, Albrektsson T. Oxidized implants and their influence on the bone response. J Mater Sci Mater Med. 2001;12(10–12):1025–31.

Xiropaidis AV, Qahash M, Lim WH, Shanaman RH, Rohrer MD, Wikesjo UM, et al. Bone-implant contact at calcium phosphate-coated and porous titanium oxide (TiUnite)-modified oral implants. Clin Oral Implants Res. 2005;16(5):532–9.

Le Guéhennec L, Soueidan A, Layrolle P, Amouriq Y. Surface treatments of titanium dental implants for rapid osseointegration. Dent Mater. 2007;23(7):844–54.

Connor PA, McQuillan AJ. Phosphate adsorption onto TiO2 from aqueous solutions: an in situ internal reflection infrared spectroscopic study. Langmuir. 1999;15(8):2916–21.

Cigada A, Cabrini M, Pedeferri P. Increasing of the corrosion resistance of the Ti6Al4 V alloy by high thickness anodic oxidation. J Mater Sci Mater Med. 1992;3(6):408–12.

Park IS, Lee MH. Effects of anodic spark oxidation by pulse power on titanium substrates. Surf Interface Anal. 2011;43(7):1030–7.

Hanawa T, Kon M, Doi H, Ukai H, Murakami K, Hamanaka H, et al. Amount of hydroxyl radical on calcium-ion-implanted titanium and point of zero charge of constituent oxide of the surface-modified layer. J Mater Sci Mater Med. 1998;9(2):89–92.

Kieswetter K, Schwartz Z, Dean D, Boyan B. The role of implant surface characteristics in the healing of bone. Crit Rev Oral Biol Med. 1996;7(4):329–45.

Anil S, Anand P, Alghamdi H, Jansen J. Dental implant surface enhancement and osseointegration. Implant dentistry: a rapidly evolving practice. New York: InTech; 2011. p. 83–108.

Suh JY, Jang BC, Zhu X, Ong JL, Kim K. Effect of hydrothermally treated anodic oxide films on osteoblast attachment and proliferation. Biomaterials. 2003;24(2):347–55.

Wu J, Liu ZM, Zhao XH, Gao Y, Hu J, Gao B. Improved biological performance of microarc-oxidized low-modulus Ti-24Nb-4Zr-7.9Sn alloy. J Biomed Mater Res B. 2010;92(2):298–306.

Pae A, Kim SS, Kim HS, Woo YH. Osteoblast-like cell attachment and proliferation on turned, blasted, and anodized titanium surfaces. Int J Oral Maxillofac Implants. 2011;26(3):475–81.

Bowers KT, Keller JC, Randolph BA, Wick DG, Michaels CM. Optimization of surface micromorphology for enhanced osteoblast responses in vitro. Int J Oral Maxillofac Implants. 1992;7(3):302–10.

Giordano C, Chiesa R, Sandrini E, Cigada A, Giavaresi G, Fini M, et al. Physical and biological characterizations of a novel multiphase anodic spark deposition coating to enhance implant osseointegration. J Mater Sci Mater Med. 2005;16(12):1221–9.

Schwarz F, Wieland M, Schwartz Z, Zhao G, Rupp F, Geis-Gerstorfer J, et al. Potential of chemically modified hydrophilic surface characteristics to support tissue integration of titanium dental implants. J Biomed Mater Res B. 2009;88B(2):544–57.

Acknowledgments

This study was funded by Dentsply, Austarlia and Wishborne trust. We wish to acknowledge the assistance of Liz Girwan, Otago Centre for Electron Microscopy, University of Otago, for her assistance in the SEM. We wish to acknowledge the assistance of Andrew McNaughton, Otago Centre for Confocal Microscopy, University of Otago, for his assistance in the confocal microscopy. We acknowledge the assistance of Paul Reynolds, Department of Chemistry for his assistance in fabrication of electrical set up. We the authors of this manuscript declare that there is no potential conflict of interest with respect to the authorship and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, A., McQuillan, A.J., A Sharma, L. et al. Spark anodization of titanium–zirconium alloy: surface characterization and bioactivity assessment. J Mater Sci: Mater Med 26, 221 (2015). https://doi.org/10.1007/s10856-015-5555-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-015-5555-7