Abstract

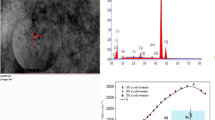

The objective of this work was to develop a synthesis procedure for the deposition of β-TCP coatings with tailored physico-chemical properties on zirconia bioceramics. The synthesis procedure involved two steps: (i) a rapid wet-chemical deposition of a biomimetic CaP coating and (ii) a subsequent post-deposition processing of the biomimetic CaP coating, which included a heat treatment between 800 and 1200 °C, followed by a short sonication in a water bath. By regulating the heating temperature the topography of the β-TCP coatings could be controlled. The average surface roughness (Ra) ranged from 42 nm for the coating that was heated at 900 °C (TCP-900) to 630 nm for the TCP-1200 coating. Moreover, the heating temperature also affected the dissolution rate of the coatings in a physiological solution, their protein-adsorption capacity and their bioactivity in a simulated body fluid.

Similar content being viewed by others

References

Tschernitschek H, Borchers L, Geurtsen W. Nonalloyed titanium as a bioinert metal–a review. Quintessence Int. 2005;36(7–8):523–30.

Hench LL, Wilson J. An introduction to bioceramics. London: World Scientific; 1999.

Zijderveld SA, Zerbo IR, van den Bergh JP, Schulten EA, ten Bruggenkate CM. Maxillary sinus floor augmentation using a beta-tricalcium phosphate (Cerasorb) alone compared to autogenous bone grafts. Int J Oral Maxillofac Implants. 2005;20(3):432–40.

Bolelli G, Stiegler N, Bellucci D, Cannillo V, Gadow R, Killinger A, et al. Deposition mechanisms in high velocity suspension spraying: case study for two bioactive materials. Surf Coat Technol. 2012;210:28–45.

Rey C, Combes C, Drouet C, Somrani S. Tricalcium phosphate-based ceramics. In: Kokubo T, editor. Bioceramics and their clinical applications. Cambridge: Woodhead Publishing; 2008. p. 326–66.

Hu JA, Wang ZY, Guan TH, Gao Y, Lv XW, Lin X, et al. In situ synthesis and fabrication of tricalcium phosphate bioceramic coating on commercially pure titanium by laser rapid forming. Surf Coat Technol. 2010;204(23):3833–7.

Stefanic M, Krnel K, Kosmac T. Novel method for the synthesis of a bioactive β-tricalcium phosphate coating on a zirconia implant. J Eur Ceram Soc. 2013;33:3455–65.

Stefanic M, Krnel K, Pribosic I, Kosmac T. Rapid biomimetic deposition of octacalcium phosphate coatings on zirconia ceramics (Y-TZP) for dental implant applications. Appl Surf Sci. 2012;258(10):4649–56.

Kokubo T. In vitro evaluation of bone bioactivity. In: Kokubo T, editor. Bioceramics and their clinical applications, vol. 9., Woodhead Publishing Series in Biomaterials. Cambridge: Woodhead Publishing; 2008. p. 165–82.

Müller L, Müller F. Preparation of SBF with different HCO3-content and its influence on the composition of biomimetic apatites. Acta Biomater. 2006;2:181–9.

Barrere F, Layrolle P, Van Blitterswijk CA, De Groot K. Biomimetic coatings on titanium: a crystal growth study of octacalcium phosphate. J Mater Sci. 2001;12(6):529–34.

Reiner T, Klinger LM, Gotman I. Biomimetic calcium phosphate growth over differently shaped Ti substrates: modeling the effect of surface curvature. Cryst Growth Des. 2011;11(1):190–5.

Reiner T, Gotman I. Biomimetic calcium phosphate coating on Ti wires versus flat substrates: structure and mechanism of formation. J Mater Sci. 2010;21(2):515–23.

Mortier A, Lemaitre J, Rouxhet PG. Temperature-programmed characterization of synthetic calcium-deficient phosphate apatites. Thermochim Acta. 1989;143:265–82.

Raynaud S, Champion E, Bernache-Assollant D, Thomas P. Calcium phosphate apatites with variable Ca/P atomic ratio, I. Synthesis, characterisation and thermal stability of powders. Biomaterials. 2002;23(4):1065–72.

Fowler BO, Moreno EC, Brown WE. Infra-red spectra of hydroxyapatite, octacalcium phosphate and pyrolysed octacalcium phosphate. Arch Oral Biol. 1966;11(5):477–92.

Berry EE. The structure and composition of some calcium-deficient apatites. J Inorg Nucl Chem. 1967;29:317–27.

Vasant SR, Joshi MJ. Synthesis and characterization of nanoparticles of calcium pyrophosphate. Mod Phys Lett B. 2011;25(1):53–62.

Ishikawa K, Ducheyne P, Radin S. Determination of the Ca/P ratio in calcium-deficient hydroxyapatite using X-ray diffraction analysis. J Mater Sci. 1993;4:165–8.

Raynaud S, Champion E, Bernache-Assollant D, Thomas P. Calcium phosphate apatites with variable Ca/P atomic ratio, I. Synthesis, characterisation and thermal stability of powders. Biomaterials. 2002;23(4):1065–72.

Mortier A, Lemaitre J, Rodrique L, Rouxhet P. Synthesis and thermal behavior of well-crystallized calcium-deficient phosphate apatite. J Solid State Chem. 1989;78:215–9.

Wennerberg A, Albrektsson T. Effects of titanium surface topography on bone integration: a systematic review. Clin Oral Implant Res. 2009;20:172–84.

Webster TJ, Ergun C, Doremus RH, Siegel RW, Bizios R. Specific proteins mediate enhanced osteoblast adhesion on nanophase ceramics. J Biomed Mater Res. 2000;51(3):475–83.

Preissner KT. Structure and biological role of vitronectin. Annu Rev Cell Biol. 1991;7(1):275–310.

Pankov R, Yamada K. Fibronectin at a glance. J Cell Sci. 2002;115(20):3861–3.

Wennerberg A, Albrektsson T. Structural influence from calcium phosphate coatings and its possible effect on enhanced bone integration. Acta Odontol Scand. 2009;67(6):333–40.

Wennerberg A, Albrektsson T. On implant surfaces: a review of current knowledge and opinions. Int J Oral Maxillofac Implants. 2010;25(1):63–74.

Le Guehennec L, Soueidan A, Layrolle P, Amouriq Y. Surface treatments of titanium dental implants for rapid osseointegration. Dent Mater. 2007;23(7):844–54.

Kondo N, Ogose A, Tokunaga K, Umezu H, Arai K, Kudo N, et al. Osteoinduction with highly purified beta-tricalcium phosphate in dog dorsal muscles and the proliferation of osteoclasts before heterotopic bone formation. Biomaterials. 2006;27(25):4419–27.

Luvizuto ER, Tangl S, Zanoni G, Okamoto T, Sonoda CK, Gruber R, et al. The effect of BMP-2 on the osteoconductive properties of β-tricalcium phosphate in rat calvaria defects. Biomaterials. 2011;32(15):3855–61.

Roy M, Vamsi Krishna B, Bandyopadhyay A, Bose S. Laser processing of bioactive tricalcium phosphate coating on titanium for load-bearing implants. Acta Biomater. 2008;4(2):324–33.

Yang Y, Agrawal CM, Kim KH, Martin H, Schulz K, Bumgardner JD, et al. Characterization and dissolution behavior of sputtered calcium phosphate coatings after different postdeposition heat treatment temperatures. J Oral Implant. 2003;29(6):270–7.

Bohner M, Lemaitre J. Can bioactivity be tested in vitro with SBF solution? Biomaterials. 2009;30(12):2175–9.

Pan HB, Zhao XL, Darvell BW, Lu WW. Apatite-formation ability—predictor of “bioactivity”? Acta Biomater. 2010;6(11):4181–8.

Mullin JW. Crystallization. Woburn: Butterworth-Heinemann; 2001.

Zhang Y, Wang M, Lin X, Huang W. Effect of substrate surface microstructure on heterogeneous nucleation behavior. J Mater Sci Technol. 2012;28(1):67–72.

Chen X, Nouri A, Li Y, Lin J, Hodgson PD, Wen CE. Effect of surface roughness of Ti, Zr, and TiZr on apatite precipitation from simulated body fluid. Biotechnol Bioeng. 2008;101(2):378–87.

Hou X, Yin G, Chen X, Liao X, Yao Y, Huang Z. Effect of akermanite morphology on precipitation of bone-like apatite. Appl Surf Sci. 2011;257(8):3417–22.

Kokubo T, Takadama H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials. 2006;27(15):2907–15.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Stefanic, M., Milacic, R., Drazic, G. et al. Synthesis of bioactive β-TCP coatings with tailored physico-chemical properties on zirconia bioceramics. J Mater Sci: Mater Med 25, 2333–2345 (2014). https://doi.org/10.1007/s10856-014-5246-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-014-5246-9