Abstract

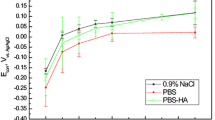

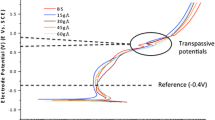

The behaviour of CoCrMo alloy has been studied in two simulated physiological solutions—NaCl and Hanks’ solutions—each containing the sodium salt of hyaluronic acid. Hyaluronic acid is a component of synovial joint fluid, so the behaviour of orthopaedic alloys in its presence needs to be assessed. Electrochemical methods, X-ray photoelectron spectroscopy and scanning electron microscopy have been used to analyse the composition, thickness and morphology of any layers formed on the alloy. The addition of hyaluronic acid shifts the corrosion potential and increases the value of polarization resistance. The presence of hyaluronic acid in simulated Hanks’ physiological solution stimulates the formation of a calcium phosphate layer, opening up the possibility for tailoring the surface properties of CoCrMo alloy. The viability of human osteoblast-like was determined using the Alamar® Blue Assay, while the osteogenic activity was evaluated by alkaline phosphatase activity. The presence of hyaluronic acid affects the alkaline phosphatase activity.

Similar content being viewed by others

References

Kasemo B. Biological surface science. Surface Sci. 2002;500:656–77.

Puleo DA, Nanci A. Understanding and controlling the bone-implant interface. Biomaterials. 1999;20:2311–21.

Xu T, Zhan N, Nichols HL, Shi D, Wen X. Modification of nanostructured materials for biomedical apllications. Mater Sci Eng C. 2007;27:579–94.

Paital SR, Dahotre NB. Calcium phosphate coatings for bio-implant applications: materials, performance factors and methodologies. Mater Sci Eng R. 2009;66:1–70.

Igual Muňoz A, Mischler S. Interactive effects of albumin and phosphate ions on the corrosion of CoCrMo implant alloy. J Electrochem Soc 2007;154: C562-70.

Hodgson AWE, Kurz S, Virtanen S, Fervel V, Olsson C-OA, Mischler S. Passive and transpassive behaviour of CoCrMo in simulated biological solutions. Electrochim Acta. 2004;49:2167–78.

Li Y-S, Wang K, He P, Huang BX, Kovacs P. Surface-enhanced Raman spectroelectrochemical studies of corrosion films on implant Co–Cr–Mo alloy in biosimulating solutions. J Raman Spectrosc. 1999;30:97–103.

Milošev I, Strehblow HH. The composition of the surface passive film formed on CoCrMo alloy in simulated physiological solution. Electrochim Acta. 2003;48:2767–74.

Milošev I. Surface treatments for biomedical applications. In: Djokic Stojan S, editor. Modern aspects of electrochemistry, vol 55. Springer; 2012. p. 1–72.

Hanawa T, Hiromoto S, Asami K. Characterization of the surface oxide film of a Co-Cr-Mo alloy after being located in quasi-biological environments using XPS. Appl Surf Sci. 2001;183:68–75.

Contu F, Elsener B, Böhni H. Characterization of implant materials in fetal bovine serum and sodium sulfate by electrochemical impedance spectroscopy. I Mechanically polished samples. J Biomed Mater Res. 2002;62:412–21.

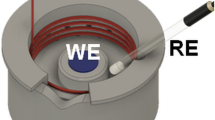

Hiromoto S, Noda K, Hanawa T. Development of electrolytic cell with cell-culture for metallic biomaterials. Corrosion Sci. 2002;44:955–65.

Cheng X, et al. Corrosion behaviour of titanium in the presence of calcium phosphate and serum proteins. Biomaterials. 2005;26:7350–6.

Milošev I. The effect of biomolecules on the behaviour of CoCrMo alloy in various simulated physiological solutions. Electrochim Acta. 2012;78:259–73.

Yadav KL, Brown PW. Formation of hydroxyapatite in water, Hank’s solution, and serum at physiological temperature. J Biomed Mater Res A. 2003;65A:158–63.

Day AJ, Sheenan JK. Hyaluronan: polysaccharide chaos to protein organisation. Curr Opin Chem Biol. 2001;11:617–22.

Barbucci R, Lamponi S, Borzacchiello A, Ambrosio L, Fini M, Torricelli P, Giardino R. Hyaluronic acid hydrogel in the treatment of osteoarthritis. Biomaterials. 2002;23:4503–13.

Gribbon P, Heng BC, Hardingham TE. The analysis of intermolecular interactions in concnetrated hyaluronan solutions suggest no evidence for chain–chain association. Biochem J. 2000;350:329–35.

Sheehan JK, Atkins EDT. X-ray fibre diffraction study of conformational changes in hyaluronate induced in the presence of sodium, potassium and calcium cations. Int J Biol Macromol. 1983;5:215–21.

Collis JJ, Embery G. Adsorption of glycosaminoglycans to commercially pure titanium. Biomaterials. 1992;13:548–52.

Ellingsen JE. A study on the mechanism of protein adsorption to TiO2. Biomaterials. 1991;12:593–6.

Hanawa T, Ota M. Calcium phosphate naturally formed on titanium in electrolyte solution. Biomaterials 1991;12:767-14.

Briggs D, Rivière JC. Spectral interpretation. In: Briggs D, Seah MP, editors. Practical surface analysis by XPS and AES. New York: Chichester; 1990.

Seah MP. Summary of ISO/TC 201 standard: iSO 14701:–surface chemical analysis–X-ray photoelectron spectroscopy–measurement of silicon oxide thickness. Surf Interface Anal. 2012;44:876–8.

Pan J, Thierry D, Leygraf C. Electrochemical impedance spectroscopy study of the passive film on titanium for implant applications. Electrochim Acta. 1996;41:1143–53.

Aziz-Kerrzo, Conroy KG, Fenelon AM, Farrell ST, Breslin CB. Electrochemical studies on the stability and corrosion resistance of titanium-based implant materials. Biomaterials 2001;21:1531-9.

Souto RA, Laz MM, Reis RL. Degradation characteristics of hydroxyapatite coatings on orthopedic TiAlV in simulated physiological media investigated by electrochemical impedance spectroscopy. Biomaterials. 2003;24:4213–21.

Hodgson AWE, Mueller Y, Forster D, Virtanen S. Electrochemical characterisation of passive films on Ti alloys under simulated biological conditions. Electrochim Acta. 2002;47:1913–23.

Tamilselvi S, Raman V, Rajendran N. Corrosion behaviour of Ti-6Al-7Nb and Ti-6Al-4 V ELI alloys in the simulated body fluid solution by electrochemical impedance spectroscopy. Electrochim Acta. 2006;52:839–46.

Metikoš-Huković M, Pilić Z, Babić R, Omanović D. Influence of alloying elements on the corrosion stability of CoCrMo implant alloy in Hank’s solution. Acta Biomater. 2006;2:693–700.

Milošev I, Blejan D, Varvara S, Muresan LM. Effect of anodic oxidation on the corrosion behaviour of Ti-based materials in simulated physiological solution. submitted.

Wagner CD, Naumkin AV, Kraut-Vass A, Allison JW, Powell CJ, Rumble JR Jr. NIST X-ray photoelectron spectroscopy database, NIST standard reference database 20, Version 3.5, Data compiled and evaluated. http://srdata.nist.gov/xps/.

Tsutsumi Y, Nishimura D, Doi H, Nomura H, Hanawa T. Difference in surface reactions between titanium and zirconium in Hank’s solution to elucidate mechanism of calcium phosphate formation on titanium using XPS and cathodic polarization. Mat Sci Eng C 2009; 29:1702-8.

Frauchiger L, Taborelli M, Aronsson B-O, Descouts P. Ion adsorption on titanium surfaces exposed to a physiological solution. Appl Surf Sci. 1999;143:67–77.

Milošev I, Jovanović Ž, Bajat JB, Jančić-Heinemann J, Mišković-Stanković VB. Surface analysis and electrochemical behaviour of aluminium pretreated by vinyltriethoxysilane films in mild NaCl solution. J Electrochem Soc. 2012;159:C303–11.

Feng B, Chen J, Zhang X. Interaction of calcium and phosphate in apatite coating on titanium with serum albumin. Biomaterials. 2002;23:2499–507.

Hughes Wassell DT, Graham E. Adsorption of bovine serum albumin on to titanium powder. Biomaterials 1196;17:859-64.

Steinberg D, Klinger A, Kohavi D, Sela MN. Adsorption of human salivary proteins to tittanium powder I: adsortpion of human salivary albumin. Biomaterials. 1995;16:1339–43.

Hay DI, Moreno EC. Differential adsorption and chemical affinities of protein for apatitic surfaces. J Dent Res. 1979;58:930–40.

Sheenan JK, Brass A, Almond A. The conformations of hyaluronan in aqueous solution: comparison of theory and experiment. Biochem Soc Trans. 1999;27:121–4.

Almond A, Brass A, Sheenan JK. Deducing polymeric structure from aqueous molecular dynamics simulations of oligosaccharides: predictions from simulations of hyaluronan tetrasacccharides compared with hydrodynamic and X-ray fibre diffraction data. J Mol Biol. 1998;284:1425–37.

Gu Z, Cai Q, He Y, Fu T, Li F. Degradation of hyaluronan by an electrochemical process. Carbohydr Polym. 2010;82:521–3.

Taylor KR, Trowbridge JM, Rudisill JA, Termeer CC, Simon JC, Galo RL. Hyaluronan fragments stimulate endothelial recognition of injury through TLR4. J Biol Chem. 2004;279:17079–84.

Scheibner S, Lutz MA, Boodoo S, Fenton MJ, Powell JD, Horton MR. Hyaluronan fragments act as an endogenous danger signal by engaging TLR2. J Immun. 2006;177:1272–81.

West DC, Hampson IN, Arnold F, Kumar S. Angiogenesis induced by degradation productts of hyaluronic acid. Science. 1985;228:1324–6.

Bhakta G, Rai B, Lim ZXH, Hui JH, Stein GS, van Wijnen AJ, Nurcombe V, Prestwich GD, Cool SM. Hyluronic acid-based hydrogels functionalized with heparin that support controlled release of bioactive BMP-2. Biomaterials. 2012;33:6113–22.

Huang Y, Luo Q, Li X, Zhang F, Zhao S. Fabrication and in vitro evaluation of the collagen/hyaluronic acid PEM coating crosslinked with functionalized RGD peptide on titanium. Acta Biomateriala. 2012;8:866–77.

Chua P-H, Neoh K-G, Kang E-T, Wang W. Surface functionalization of titanium with hyaluronic acid/chitosan polelectrolyte multilayers and RGD for promoting osteoblast functions and inhibiting bacterial adhesion. Biomaterials. 2008;29:1412–21.

Park JK, Shim JH, Kang KS, Yeom J, Jung HS, Kim JY, Lee KH, Kim TH, Kim SY, Cho DW, Hahn SK. Solid free-form fabrication of tissue engineering scaffolds with a poly(lactic-co-glycolic) grafted hyaluronic acid conjugate encapsulating an intact bone morphogenetic protein-2/poly(ethylene glycol) complex. Adv Funct Mater. 2011;21:2906–12.

Jiao Y, Liu Z, Shao X, Zhou C. Protein adsorption and cytocompatibility of poly(l-lactic acid) surfaces modified with biomacromolecules. J Appl Polymer Sci. 2012;125:E501–10.

Acknowledgments

The authors thank Mojca Seručnik, BSc, and Gregor Žerjav, BSc, for valuable experimental work, Gregor Kapun, BSc, of the National Institute of Chemistry for expertise in the FE-SEM analysis, Dr. Janez Kovač for valuable comments on XPS measurements, and dr. Antonija Lesar for fruitful discussions. Human osteosarcoma (HOS), a human osteoblast-like cell line, was kindly donated by prof. Janja Marc, Faculty of Pharmacy, University of Ljubljana. Financial support by the Slovenian Research Agency is acknowledged (Grants No. J1-2243 and J1-4136).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Milošev, I., Hmeljak, J. & Cör, A. Hyaluronic acid stimulates the formation of calcium phosphate on CoCrMo alloy in simulated physiological solution. J Mater Sci: Mater Med 24, 555–571 (2013). https://doi.org/10.1007/s10856-012-4827-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-012-4827-8