Abstract

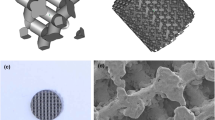

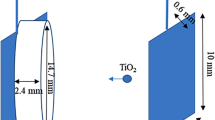

Open-pore titanium scaffolds were fabricated by sintering of compressed mixtures of TiH1.924 and urea. Spherical and irregular shaped space holders were used to investigate the effect of pore shape on cellular behavior. After removal of the space holder, the shape of the spacers was replicated to the pores. Average diameter of the pores was in the range of 300–600 μm. SEM images showed that titanium hydride resulted in higher surface roughness and larger micro porosities than pure titanium. In vitro evaluations were carried out by using MTT assay, measuring alkaline phosphatase activity and alizarin red staining in flow perfusion bioreactor for cell culture. Observations revealed excellent attachment and proliferation of G-292 cells to the highly porous scaffolds fabricated with titanium hydride and urea of this research.

Similar content being viewed by others

References

Hutmacher DW. Polymeric scaffolds in tissue engineering bone and cartilage. Biomaterials. 2000;21:2529–43.

Freyman TM, Yannas IV, Gibson LJ. Cellular materials as porous scaffolds for tissue engineering. Prog Mater Sci. 2001;46:273–82.

Jin QM, Takita H, Kohgo T, Atsumi K, Itoh H, Kuboki Y. Effects of geometry of hydroxyapatite as a cell substratum in BMP-induced ectopic bone formation. J Biomed Mater Res. 2000;51:491–9.

Dong J, Kojima H, Uemura T, Kikuchi M, Tateishi T, Tanaka J. In vivo evaluation of a novel porous hydroxyapatite to sustain osteogenesis of transplanted bone marrow-derived osteoblastic cells. J Biomed Mater Res A. 2001;57:208–16.

Damien E, Hing K, Saeed S, Revell PA. A preliminary study on the enhancement of the osteointegration of a novel synthetic hydroxyapatite scaffold in vivo. J Biomed Mater Res A. 2003;66:241–6.

Takemoto M, Fujibayashi S, Neo M, Suzuki J, Kokubo T, Nakamura T. Mechanical properties and osteoconductivity of porous bioactive titanium. Biomaterials. 2005;26(6014–23):6014–23.

Fujibayashi S, Neo M, Kim HM, Kokubo T, Nakamura T. Osteoinduction of porous bioactive titanium metal. Biomaterials. 2004;25:443–50.

Ryan G, Pandit A, Apatsidis DP. Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials. 2006;27:2651–70.

Turner TM, Sumner DR, Urban RM, Rivero DP, Galante JO. A comparative study of porous coatings in a weight-bearing total hiparthroplasty model. J Bone Joint Surg. 1986;68:1396–409.

Cook SD, Walsh KA, Haddad RJ Jr. Interface mechanics and bone growth into porous Co–Cr–Mo alloy implants. Clin Orthop. 1985;193:271–80.

Clemow AJ, Weinstein AM, Klawitter JJ, Koeneman J, Anderson J. Interface mechanics of porous titanium implants. J Biomed Mater Res A. 1981;15:73–82.

Cameron HU, Pilliar RM, Macnab I. The rate of bone ingrowth into porous metal. J Biomed Mater Res B. 1976;10:295–302.

Mishra S, Knothe-Tate ML. Effect of lacunocanalicular architecture on hydraulic conductance in bone tissue: Implications for bone health and evolution. Anatomical Rec. 2003;273A:752–62.

Bobyn J, Miller J. Features of biologically fixed devices. In: Simon, S.R. (Ed.) orthopaedic basic science. Am Acad Orthop Surg. 1994;10:613–6.

Bobyn J, Pilliar RM, Cameron H, Weatherly G. The optimum pore size for the fixation of porous surfaced metal implants by ingrowth of bone. Clin Orthop. 1980;150:263–70.

Itala AI, Ylanen HO, Ekholm C, Karlsson KH, Aro HT. Pore diameter of more than 100 micron is not requisite for bone ingrowth in rabbits. J Biomed Mater Res B. 2001;58:679–83.

Wenjuan N, Chenguang B, GuiBao Q, Qiang W. Processing and properties of porous titanium using space holder technique. Mater Sci Eng A. 2009;506:148–51.

Ye B, Dunand DC. Titanium foams produced by solid-state replication of NaCl powders. Mater Sci Eng A. 2010;528:691–7.

Wen CE, Mabuchi M, Yamada Y, Shimojima K, Chino Y, Ashina T. Processing of biocompatible porous Ti and Mg. Scripta Mater. 2001;45:1147–53.

Esen Z, Bor S. Processing of titanium foams using magnesium spacer particles. Scripta Mater. 2007;56:341–4.

Ueno T, Tsukimura N, Yamada M, Ogawa T. Enhanced bone- integration capability of alkali- and heat-treated nanopolymorphic titanium in micro-to-nanoscale hierarchy. Biomaterials. 2011;32:7297–308.

Fu Q, Hong Y, Liu X, Fan H, Zhang X. A hierarchically graded bioactive scaffold bonded to titanium substrates for attachment to bone. Biomaterials. 2011;32:7333–46.

JCPDS. Powder diffraction file, ALPhabetical index. Inorganic Materials. Swarthmore: JCPDS; 1979.

Wu S, Liu X, Yeung KWK, Hu T, Xu Z, Chung JCY, Chu PK. Hydrogen release from titanium hydride in foaming of orthopedic NiTi scaffolds. Acta Biomater. 2011;7:1387–97.

Sandim HRZ, Morante BV, Suzuki PA. Kinetics of thermal decomposition of titanium hydride powder using in situ high-temperature X-ray diffraction (HTXRD). Mater Res. 2005;8:293–7.

Sugita Y, Ishizaki K, Iwasa F, Ueno T, Minamikawa H, Yamada M, Suzuki T, Ogawa T. Effects of pico-to-nanometer-thin TiO2 coating on the biological properties of microroughened titanium. Biomaterials. 2011;32:8374–84.

Li JP, Habibovic P, Doel MV, Wilson CE, Wijn JRD, Blitterswijk CAV, Groot KD. Bone ingrowth in porous titanium implants produced by 3D fiber deposition. Biomaterials. 2007;28:2810–20.

Zhang Q, Leng Y, Xin R. A comparative study of electrochemical deposition and biomimetic deposition of calcium phosphate on porous titanium. Biomaterials. 2005;26:2857–65.

Wu Y, Zitelli JP, TenHuisen KS, Yu X, Libera MR. Differential response of staphylococci and osteoblasts to varying titanium surface roughness. Biomaterials. 2011;32:951–60.

Acknowledgments

Kind cooperation of Mr. D. Shamaee who provided tools and instruments for fabrication of the scaffolds is greatly appreciated. Deputy of research of Sharif University of Technology is also thanked for continued support of Seed of Design and Accomplishment of New Processes for Production and Application of Advanced Materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dezfuli, S.N., Sadrnezhaad, S.K., Shokrgozar, M.A. et al. Fabrication of biocompatible titanium scaffolds using space holder technique. J Mater Sci: Mater Med 23, 2483–2488 (2012). https://doi.org/10.1007/s10856-012-4706-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-012-4706-3