Abstract

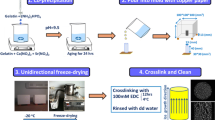

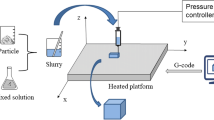

Highly porous calcium phosphate (CaP) scaffolds for bone-tissue engineering were fabricated by combining a robocasting process with a sol–gel synthesis that mixed Calcium Nitrate Tetrahydrate and Triethyl Phosphite precursors in an aqueous medium. The resulting gels were used to print scaffolds by robocasting without the use of binder to increase the viscosity of the paste. X-ray diffraction analysis confirmed that the process yielded hydroxyapatite and β-tricalcium phosphate biphasic composite powders. Thus, the scaffold composition after crystallization of the amorphous structure could be easily modified by varying the initial Ca/P ratio during synthesis. The compressive strengths of the scaffolds are ~6 MPa, which is in the range of human cancellous bone (2–12 MPa). These highly porous scaffolds (~73 vol% porosity) are composed of macro-pores of ~260 μm in size; such porosity is expected to enable bone ingrowth into the scaffold for bone repair applications. The chemistry, porosity, and surface topography of such scaffolds can also be modified by the process parameters to favor bone formation. The studied sol–gel process can be used to coat these scaffolds by dip-coating, which induces a significant enhancement of mechanical properties. This can adjust scaffold properties such as composition and surface morphology, which consequently may improve their performances.

Similar content being viewed by others

References

Hench LL. Bioceramics. J Am Ceram Soc. 1998;81:1705.

Ramay HRR, Zhang M. Biphasic calcium phosphate nanocomposite porous scaffolds for load-bearing bone tissue engineering. Biomaterials. 2004;25:5171.

LeGeros RZ, Lin S, Rohanizadeh R, Mijares D, LeGeros JP. Biphasic calcium phosphate bioceramics: Preparation, properties and applications. J Mater Sci Med. 2003;14:201.

Daculsi G, LeGeros RZ, Nery E, Lynch K, Kerebel B. Transformation of biphasic calcium phosphate ceramics in vivo: ultrastructural and physicochemical characterization. J Biomed Mater Res. 1989;23(8):883.

LeGeros RZ, Daculsi G, LeGeros JP. Bioactive Bioceramics. In: Pietrzak WS, editor. Orthopedic Biology and Medicine: Musculoskeletal Tissue Regeneration: Biological Materials and Methods, Chapter 8. New Jersey: Humana Press Inc; 2008. p. 153–81.

LeGeros RZ, LeGeros JP. Hydroxyapatite. In: Kokubo T, editor. Bioceramics and their clinical applications. Cambridge: Woodhead Publishing Ltd; 2008. p. 367–94.

Malard O, Guicheux J, Bouler JM, Gauthier O, Beauvillain de Montreuil C, Aguado E, Pilet P, LeGeros RZ, Daculsi G. Calcium phosphate scaffold and bone marrow for bone reconstruction in irradiated area: a dog study. Bone. 2005;36:323.

Arinzeh TL, Peter SJ, Archambault MP, Van Den Bos C, Gordon S, Kraus K, Smith A, Kadiyala S. Allogeneic mesynchymal stem cells rgenerate bone in a critical sized canine segmental defect. J Bone Jt Surg Am. 2003;85A:1927.

Miranda P, Pajares A, Saiz E, Tomsia AP, Guiberteau F. Mechanical properties of calcium phosphate scaffolds fabricated by robocasting. J Biomed Mater Res A. 2008;85A:218.

Daculsi G, Passuti N, Martin S, Deudon C, Legeros RZ, Raher S. Macroporous calcium phosphate ceramic for long bone surgery in humans and dogs: Clinical and histological study. J Biomed Mater Res. 1990;24(3):379.

Wang J, Shaw LL. Synthesis of high purity hydroxyapatite nanopowder via sol–gel combustion process. J Mater Sci. 2009;20:1223.

Sanosh KP, Chu MC, Balakrishnan A, Kim TN, Cho SJ. Sol–gel synthesis of pure nano sized β-tricalcium phosphate crystalline powders. Curr Appl Phys. 2010;10:68.

Gupta R, Kumar A. Bioactive materials for biomedical applications using sol–gel technology. Biomed Mater. 2008;3:034005.

Raynaud S, Champion E, Bernache-Assollant D, Thomas P. Calcium phosphate apatites with variable Ca/P atomic ratio I. Synthesis, characterisation and thermal stability of powders. Biomaterials. 2002;23:1065.

Fellah BH, Layrolle P. Sol–gel synthesis and characterization of macroporous calcium phosphate bioceramics containing microporosity. Acta Biomater. 2009;5:735.

Liu DM, Troczynski T, Tseng WJ. Water-based sol–gel synthesis of hydroxyapatite: process development. Biomaterials. 2001;22:1721.

Liu DM, Yang Q, Troczynski T. Sol–gel hydroxyapatite coatings on stainless steel substrates. Biomaterials. 2002;23:691.

Manso M, Langlet M, Jiménez C, Martínez-Duart JM. Hydroxyapatite coatings obtained by the thermal activation of polymeric sols. Int J Inorg Mater. 2001;3:1153.

Manso M, Langlet M, Jiménez C, Martínez-Duart JM. Microstructural study of aerosol–gel derived hydroxyapatite coatings. Biomol Eng. 2002;19:63.

Manso-Silván M, Langlet M, Jiménez C, Fernández M, Martínez-Duart JM. Calcium phosphate coatings prepared by aerosol-gel. J Eur Ceram Soc. 2003;23:243.

Stoch A. Jastrze¸bski W, Długoń E, Lejda W, Trybalska B, Stoch GJ, Adamczyk A. Sol–gel derived hydroxyapatite coatings on titanium and its alloy Ti6Al4 V. J Mol Struct. 2005;744–747:633.

Chen QZ, Thompson ID, Boccaccini AR. 45S5 Bioglass®-derived glass–ceramic scaffolds for bone tissue engineering. Biomaterials. 2006;27:2414.

Rezwan K, Chen QZ, Blaker JJ, Boccaccini AR. Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering. Biomaterials. 2006;27:3413.

Jones JR, Ehrenfried LM, Hench LL. Optimising bioactive glass scaffolds for bone tissue engineering. Biomaterials. 2006;27:964.

Jones JR, Tsigkou O, Coates EE, Stevens MM, Polak JM, Hench LL. Extracellular matrix formation and mineralization on a phosphate-free porous bioactive glass scaffold using primary human osteoblast (HOB) cells. Biomaterials. 2007;28:1653.

Almeida RM, Gama A, Vueva Y. Bioactive sol–gel scaffolds with dual porosity for tissue engineering. J Sol-Gel Sci Technol. 2011;57:336.

Marques AC, Jain H, Kiely C, Song K, Kiely CJ, Almeida RM. Nano/macroporous monolithic scaffolds prepared by the sol–gel method. J Sol-Gel Sci Technol. 2009;51:42.

Peña J, Román J, Cabañas MV, Vallet-Regí M. An alternative technique to shape scaffolds with hierarchical porosity at physiological temperature. Acta Biomater. 2010;6:1288.

Hulbert SF, Morrison SJ, Klawitte JJ. Tissue reaction to three ceramics of porous and non-porous structures. J Biomed Mater Res. 1972;6:347.

Langer R, Vacanti JP. Tissue engineering. Science. 1993;260:920.

Saiz E, Gremillard L, Menendez G, Miranda P, Gryn K, Tomsia AP. Preparation of porous hydroxyapatite scaffolds. Mater Sci Eng C. 2007;27:546.

Ben-Nissan B. Natural bioceramics: from coral to bone and beyond. Curr Opin Solid State Mater Sci. 2003;7:283.

Bohner M, Van Lenthe GH, Grunenfelder S, Hirsiger W, Evison R, Muller R. Synthesis and characterization of porous beta-tricalcium phosphate blocks. Biomaterials. 2005;26:6099.

Sous M, Bareille R, Rouais F, Clement D, Amedee J, Dupuy B, Baquey Ch. Cellular biocompatibility and resistance to compression of macroporous beta-tricalcium phosphate ceramics. Biomaterials. 1998;19:2147.

Deville S, Saiz E, Tomsia AP. Freeze casting of hydroxyapatite scaffolds for bone tissue engineering. Biomaterials. 2006;27:5480.

Franco J, Hunger P, Launey ME, Tomsia AP, Saiz E. Direct write assembly of calcium phosphate scaffolds using a water-based hydrogel. Acta Biomater. 2010;6:218.

Miranda P, Saiz E, Gryn K, Tomsia AP. Sintering and robocasting of β-tricalcium phosphate scaffolds for orthopaedic applications. Acta Biomater. 2006;2:457.

Duoss EB, Twardowski M, Lewis JA. Sol–gel inks for direct-write assembly of functional oxides. Adv Mater. 2007;19:3485.

Case ED, Smith IO, Baumann MJ. Microcracking and porosity in calcium phosphates and the implications for bone tissue engineering. Mater Sci Eng A. 2005;390:246.

Wang JW, Hon MH. Sugar-mediated chitosan/poly(ethylene glycol)-β-dicalcium pyrophosphate composite: Mechanical and microstructural properties. J Biomed Mater Res A. 2003;64A:262.

Murphy CM, Haugh MG, O’Brien FJ. The effect of mean pore size on cell attachment, proliferation and migration in collagen–glycosaminoglycan scaffolds for bone tissue engineering. Biomaterials. 2010;31:461.

Oh SH, Park IK, Kim JM, Lee JH. In vitro and in vivo characteristics of PCL scaffolds with pore size gradient fabricated by a centrifugation method. Biomaterials. 2007;28:1664.

Karageorgiou V, Kaplan D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials. 2005;26:5474.

Petite H, Viateau V, Bensaïd W, Meunier A, De Pollak C, Bourguignon M, Oudina K, Sedel L, Guillemin G. Tissue-engineered bone regeneration. Nat Biotechnol. 2000;18:959.

Pineda LM, Büsing M, Meinig RP, Gogolewski S. Bone regeneration with resorbable polymeric membranes. III. Effect of poly(L-lactide) membrane pore size on the bone healing process in large defects. J Biomed Mater Res. 1996;31:385.

Campbell CE, Von Recum AF. Microtopography and soft tissue response. J Invest Surg. 1989;2:51.

Yang S, Leong KF, Du Z, Chua CK. The design of scaffolds for use in tissue engineering. Part I. Traditional factors. Tissue Eng. 2001;7:679.

Carter DR, Hayes WC. Bone compressive strength: the influence of density and strain rate. Science. 1976;194:1174.

Wagoner Johnson AJ, Herschler BA. A review of the mechanical behavior of CaP and CaP/polymer composites for applications in bone replacement and repair. Acta Biomater. 2011;7:16.

Cordell JM, Vogl ML, Wagoner Johnson AJ. The influence of micropore size on the mechanical properties of bulk hydroxyapatite and hydroxyapatite scaffolds. J Mech Behav Biomed Mater. 2009;2:560.

Bignon A, Chouteau J, Chevalier J, Fantozzi G, Carret J, Chavassieux P, Boivin G, Melin M, Hartmann D. Effect of micro- and macroporosity of bone substitutes on their mechanical properties and cellular response. J Mater Sci Mater Med. 2003;14:1089.

Acknowledgments

This work was supported by the National Institutes of Health/National Institute of Dental and Craniofacial Research Grant No. 1 R01 DE015633.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Houmard, M., Fu, Q., Saiz, E. et al. Sol–gel method to fabricate CaP scaffolds by robocasting for tissue engineering. J Mater Sci: Mater Med 23, 921–930 (2012). https://doi.org/10.1007/s10856-012-4561-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-012-4561-2