Abstract

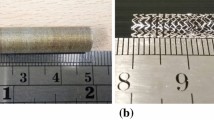

This paper reports electrochemical polishing (EP) of 316L stainless-steel structures patterned using micro-electro-discharge machining (μEDM) for application to stents including intelligent stents based on micro-electro-mechanical-systems technologies. For the process optimization, 10 μm deep cavities μEDMed on the planar material were polished in a phosphoric acid-based electrolyte with varying current densities and polishing times. The EP condition with a current density of 1.5 A/cm2 for an EP time of 180 s exhibited the highest surface quality with an average roughness of 28 nm improved from~400 nm produced with high-energy μEDM. The EP of μEDMed surfaces was observed to produce almost constant smoothness regardless of the initial roughness determined by varying discharge energies. Energy-dispersive X-ray spectroscopy was performed on the μEDMed surfaces before and after EP. A custom rotational apparatus was used to polish tubular test samples including stent-like structures created using μEDM, demonstrating uniform removal of surface roughness and sharp edges from the structures.

Similar content being viewed by others

References

Logan AG, Bradley D. Sleep apnea and cardiovascular disease. Curr Hypertens Rep. 2010;12:182–8.

Al-Suwaidi J, Berger PB, Holmes DR. Coronary artery stents. JAMA. 2000;284(14):1828–36.

Al-Mubarak N, Iyer SS. Carotid artery stenting for the high surgical risk patients. J Cardiovasc Surg. 2005;46(1):1–8.

Cullen SN, Chapman RW. Review article: Current management of primary sclerosing cholangitis. Alimentary Pharmacol Therap. 2005;21(8):933–48.

Monkemuller KE, Kahl S, Malfertheiner P. Endoscopic therapy of chronic pancreatitis. Dig Dis. 2004;22(3):280–91.

Saito Y, Imamura H. Airway stenting. Surg Today. 2005;35(4):265–70.

Carrau RL. Use of stents in head and neck surgery. Curr Opin Otolaryngol Head Neck Surg. 2005;13(2):105–6.

Bertand OF, Sipehia R, Mongrain R, Rodes J, Tardif J, Bilodeau L, Cote G, Bourassa MG. Biocompatibility aspects of new stent technology. J Am Coll Cardiol. 1998;32:562–71.

Kathuria YP. Laser microprocessing of metallic stent for medical therapy. J Mater Process Technol. 2005;170(3):545–50.

Momma C, Knop U, Nolte S. Laser cutting of slotted tube coronary stents—state-of-the-art and future developments. Prog Biomed Res. 1999;4(1):39–44.

Raval A, Choubey A, Engineer C, Kothwala D. Development and assessment of 316LVM cardiovascular stent. Mater Sci Eng A. 2004;386(1–2):331–43.

Masaki T, Kawata K, Masuzawa T. Micro electro-discharge machining and its applications. Proc. IEEE Int. Workshop on MicroElectro Mechanical Systems (MEMS ’90). Napa Valley, California; 1990. p. 21–26.

Takahata K. Micro-electro-discharge machining technologies for MEMS. In Takahata K,editor. Micro electronic and mechanical systems. IN-TECH; 2009 p. 143–164.

Takahata K, Gianchandani YB. A planar approach for manufacturing cardiac stents: design, fabrication, and mechanical evaluation. J Microelectromech Syst. 2004;13:933–9.

Takahata K, Gianchandani YB, Wise KD. Micromachined antenna stents and cuffs for monitoring intraluminal pressure and flow. J Microelectromech Syst. 2006;15:1289–98.

Green SR, Gianchandani YB. Wireless magnetoelastic monitoring of biliary stents. J Microelectromech Syst. 2009;18(1):64–78.

Hocheng H, Kao PS, Chen YF. Electropolishing of 316L stainless steel for anticorrosion passivation. J Mater Eng Perform. 2001;10:414–8.

Lee ES. Machining characteristics of the electropolishing of stainless steel (STS316L). Int J Adv Manuf Technol. 2000;16:591–9.

Kao PS, Hocheng H. Optimization of electrochemical polishing of stainless steel by grey relational analysis. J Mater Process Technol. 2003;140:255–9.

Abbott AP, Capper G, McKenzie KJ, Ryder KS. Voltammetric and impedance studies of the electropolishing of type 316 stainless steel in a choline chloride based ionic liquid. Electrochim Acta. 2006;51:4420–5.

Chen SC, Tu GC, Huang CA. The electrochemical polishing behavior of porous austenitic stainless steel (AISI 316L) in phosphoric-sulfuric mixed acids. Surf Coat Technol. 2005;200:2065–71.

Scheerder ID, Sohier J, Verbeken E, Froyen L, Humbeeck JV. Biocompatibility of coronary stent materials: effect of electrochemical polishing. Materialwissenschaft und Werkstofftechnik. 1999;32(2):142–8.

Haiıdopoulos M, Turgeon S, Sarra-Bournet C, Laroche G, Mantovani D. Development of an optimized electrochemical process for subsequent coating of 316 stainless steel for stent applications. J Mater Sci: Mater Med. 2006;17:647–57.

Zhao H, Humbeeck JV, Sohier J, Scheerder IV. Electrochemical polishing of 316L stainless steel slotted tube coronary stents. J Mater Sci: Mater Med. 2002;13:911–6.

Bhuyan A, Gregory B, Lei H, Yee SY, Gianchandani YB. Pulse and DC electropolishing of stainless steel for stents and other devices. IEEE Sensors, Irvine, California; 2005 p. 314–317.

Fleischer J, Masuzawa T, Schmidt J, Knoll M. New applications for micro-EDM. J Mater Process Technol. 2004;149:246–9.

Kwok SCH, Wang J, Chu PK. Surface energy, wettability, and blood compatibility phosphorus doped diamond-like carbon films. Diam Relat Mater. 2005;14:78–85.

Zhou J, Yun J, Zang XP, Shen J, Lin SC. Platelet adhesion and protein adsorption on silicone rubber surface by ozone-induced grafted polymerization with carboxybetaine monomer. Colloid Surface B. 2005;41:55–62.

Wootton DM, Ku DN. Fluid mechanics of vascular systems, diseases, and thrombosis. Annu Rev Biomed Eng. 1999;1:299–329.

Tsunoda N, Kokubo K, Sakai K, Fukuda M, Miyazaki M, Hiyoshi T. Surface roughness of cellulose hollow fiber dialysis membranes and platelet adhesion. ASAIO J. 1999;45:418–23.

Hecker JF, Scandrett LA. Roughness and thrombogenicity of the outer surfaces of intravascular catheters. J Biomed Mater Res. 1985;19:381–95.

Zingg W, Neumann AW, Strong AB, Hum OS, Absolom DR. Effect of surface roughness on platelet adhesion under static and under flow conditions. Can J Surg. 1982;25:16–9.

Wong YS, Rahman M, Lim HS, Han H, Ravi N. Investigation of micro-EDM material removal characteristics using single RC-pulse discharges. J Mater Process Technol. 2003;140:303–7.

Acknowledgments

This work was partially supported by the Natural Sciences and Engineering Research Council of Canada, the Canadian Institutes of Health Research, the Canada Foundation for Innovation, and the British Columbia Knowledge Development Fund. K. Takahata is supported by the Canada Research Chairs program. The authors would like to thank Dr. Boris Stoeber for access to the optical profilometer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lappin, D., Mohammadi, A.R. & Takahata, K. An experimental study of electrochemical polishing for micro-electro-discharge-machined stainless-steel stents. J Mater Sci: Mater Med 23, 349–356 (2012). https://doi.org/10.1007/s10856-011-4513-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4513-2