Abstract

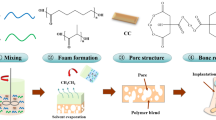

In this study, poly(ε-caprolactone) (PCL)/poly(ethylene oxide) (PEO) (50:50 wt%) immiscible blend was used as a model system to investigate the feasibility of a novel solventless fabrication approach that combines cryomilling, compression molding and porogen leaching techniques to prepare interconnected porous scaffolds for tissue engineering. PCL was cryomilled with PEO to form blend powders. Compression molding was used to consolidate and anneal the cryomilled powders. Selective dissolution of the PEO with water resulted in interconnected porous scaffolds. Sodium chloride salt (NaCl) was subsequently added to cryomilled powder to increase the porosity of scaffolds. The prepared scaffolds had homogeneous pore structures, a porosity of ~50% which was increased by mixing salt with the blend (~70% for 60% wt% NaCl), and a compressive modulus and strength (ε = 10%) of 60 and 2.8 MPa, respectively. The results of the study confirm that this novel approach offers a viable alternative to fabricate scaffolds.

Similar content being viewed by others

References

Lee MH, Arcidiacono JA, Bilek AM, Wille JJ, Hamill CA, Wonnacott KM, et al. Considerations for tissue-engineered and regenerative medicine product development prior to clinical trials in the United States. Tissue Eng Part B Rev. 2009;1–14.

Williams DJ, Sebastine IM. Tissue engineering and regenerative medicine: manufacturing challenges. IEE Proc Nanobiotechnol. 2005;152:207–10.

Gabay O, Sanchez C, Taboas JM. Update in cartilage bio-engineering. Joint Bone Spine. 2010;77(4):283–6.

Stoddart MJ, Grad S, Eglin D, Alini M. Cells and biomaterials in cartilage tissue engineering. Regen Med. 2009;4(1):81–98.

Tanaka Y, Yamaoka H, Nishizawa S, Nagata S, Ogasawara T, Asawa Y, et al. The optimization of porous polymeric scaffolds for chondrocyte/atelocollagen based tissue-engineered cartilage. Biomaterials. 2010;31:4506–16.

Ikeda R, Fujioka H, Nagura I, Kokubu T, Toyokawa N, Inui A, et al. The effect of porosity and mechanical property of a synthetic polymer scaffold on repair of osteochondral defects. Int Orthop. 2009;33:821–8.

Leung L, Perron J, Naguib HE. A study of the mechanics of porous PLGA 85-15 scaffold in compression. Polym Polym Compos. 2007;15(6):437–43.

Jell G, Verdejo R, Safinia L, Shaffer MS, Stevens MM, Bismarck A. Carbon nanotube-enhanced polyurethane scaffolds fabricated by thermally induced phase separation. J Mater Chem. 2008;18:1865–72.

Shin HJ, Lee CH, Cho IH, Kim Y-J, Lee Y-J, Kim IA, et al. Electrospun PLGA nanofiber scaffolds for articular cartilage reconstruction: mechanical stability, degradation and cellular responses under mechanical stimulation in vitro. J Biomater Sci Polymer Edn. 2006;17(1–2):103–19.

Martinez-Diaz S, Garcia-Giralt N, Lebourg M, Gómez-Tejedor J-A, Vila G, Caceres E, et al. In vivo evaluation of 3-dimensional polycaprolactone scaffolds for cartilage repair in rabbits. Am J Sports Med. 2010;38:509–19.

Lebourg M, Sabater Serra R, Más Estellés J, Hernández Sánchez F, Gómez Ribelles JL, Suay Antón J. Biodegradable polycaprolactone scaffold with controlled porosity obtained by modified particle-leaching technique. J Mater Sci Mater Med. 2008;19:2047–53.

Woodfield TB, Malda J, De Wijn J, Peters F, Riesle J, Van Blitterswijk CA. Design of porous scaffolds for cartilage tissue engineering using a three-dimensional fiber-deposition technique. Biomaterials. 2004;25:4149–61.

Woodfield TB, Guggenheim M, Von Rechenberg B, Riesle J, Van Blitterswijk CA, Wedler V. Rapid prototyping of anatomically shaped, tissue-engineered implants for restoring congruent articulating surfaces in small joints. Cell Prolif. 2009;42(4):485–97.

Reignier J, Huneault MA. Preparation of interconnected poly(ε-caprolactone) porous scaffolds by a combination of polymer and salt particulate leaching. Polymer. 2006;47:4703–17.

Washburn NR, Simon CG, Tona A, Elgendy HM, Karim A, Amis EJ. Co-extrusion of biocompatible polymers for scaffolds with co-continuous morphology. J Biomed Mater Res. 2002;60(1):20–9.

Sarazin P, Favis BD. Morphology control in co-continuous poly(L-lactide)/polystyrene blends: a route towards highly structured and interconnected porosity in poly(L-lactide) materials. Biomacromolecules. 2003;4:1669–79.

Yuan Z, Favis BD. Macroporous poly(l-lactide) of controlled pore size derived from the annealing of co-continuous polystyrene/poly(l-lactide) blends. Biomaterials. 2004;25:2161–70.

Sarazin P, Roy X, Favis BD. Controlled preparation and properties of porous poly(l-lactide) obtained from a co-continuous blend of two biodegradable polymers. Biomaterials. 2004;25:5965–78.

Sarazin P, Virgilio N, Favis BD. Influence of the porous morphology on the in vitro degradation and mechanical properties of poly(L-lactide) disks. J Appl Polym Sci. 2006;100(2):1039–47.

Zhu YG, Li ZQ, Zhang D, Tanimoto T. Abs-iron nanocomposites prepared by cryomilling. J Appl Polym Sci. 2006;99:501–5.

Zhu YG, Li ZQ, Gu JJ, Zhang D, Tanimoto T. Polyaniline-iron nanocomposites prepared by cryomilling. J Polym Sci B Polym Phys. 2006;44:3157–64.

Smith AP, Ade H, Koch CC, Spontak RJ. Solid-state blending of polymers by cryogenic mechanical alloying. In: Anastasiadis SH, Karim A, Ferguson GS, editors. Materials research society symposium 2000;629. p. FF691-6.

Vertuccio L, Gorrasi G, Sorrentino A, Vittoria V. Nano clay reinforced PCL/starch blends obtained by high energy ball milling. Carbohydr Polym. 2009;75:172–9.

Chen Z, Wang Q. Pan-milling mixing—a novel approach to forming polymer blends and controlling their morphology. Polym Int. 2001;50(9):966–72.

Masuda J, Torkelson JM. Dispersion and major property enhancements in polymer/multiwall carbon nanotube nanocomposites via solid-state shear pulverization followed by melt mixing. Macromolecules. 2008;41:5974–7.

Tao Y, Kim J, Torkelson JM. Achievement of quasi-nanostructured polymer blends by solid-state shear pulverization and compatibilization by gradient copolymer addition. Polymer. 2006;47:6773–81.

Suryanarayana C. Mechanical alloying and milling. Prog Mater Sci. 2001;46:1–184.

Zhu YG, Li ZQ, Zhang D, Tanimoto T. PET-SiO2 nanocomposites prepared by cryomilling. J Polym Sci B Polym Phys. 2006;44:1161–7.

Martin, JP. An investigation of the microstructure and properties of a cryogenically mechanically alloyed polycarbonate-poly(ether ether ketone) system [Dissertation]. Blacksburg (VA): Virginia Polytechnic Institute and State University; 2001. Available from URL: http://scholarlibvtedu/theses/available/etd-11292001-141959/.

Smith AP, Spontak RJ, Ade H, Smith SD, Koch CC. High-energy cryogenic blending and compatibilizing of immiscible polymers. Adv Mater. 1999;11(15):1277–81.

Wan Y, Wu H, Cao X, Siqin Dalai S. Compressive mechanical properties and biodegradability of porous poly(caprolactone)/chitosan scaffolds. Polym Degrad Stabil. 2008;93:1736–41.

Eastmond GC. Poly(ε-caprolactone) Blends. In: Advances in Polymer Science: Biomedical Applications/Polymer Blends; 149. New York: Springer Berlin-Heidelberg; 2000, p. 59–223.

Mano JF, Sousa RA, Boesel LF, Neves NM, Reis RL. Bioinert, biodegradable and injectable polymeric matrix composites for hard tissue replacement: state of the art and recent developments. Compos Sci Technol. 2004;64:789–817.

Terife G, Narh KA. Creating polymer-carbon nanotubes nanocomposites by cryomilling. ANTEC 2009 Plastics: Annual Technical Conference Proc. 2009;1:349–53.

Sorrentino A, Gorrasi G, Tortora M, Vittoria V, Costantino U, Marmottini F, et al. Incorporation of Mg–Al hydrotalcite into a biodegradable Poly(ε-caprolactone) by high energy ball milling. Polymer. 2005;46:1601–8.

Gross KA, Rodriguez-Lorenzo LM. Biodegradable composite scaffolds with an interconnected spherical network for bone tissue engineering. Biomaterials. 2004;25:4955–62.

Beskardes IG, Gümüsderelioglu M. Biomimetic apatite-coated PCL scaffolds: effect of surface nanotopography on cellular functions. J Bioact Compat Polym. 2009;24:507–24.

Correlo VM, Boesel LF, Pinho E, Costa-Pinto AR, Alves da Silva ML, Bhattacharya M, et al. Melt-based compression-molded scaffolds from chitosan/polyester blends and composites: morphology and mechanical properties. J Biomed Mater Res A. 2009;91(2):489–504.

Varga F, Drzík M, Handl M, Chlpík J, Kos P, Filová E, et al. Biomechanical characterization of cartilages by a novel approach of blunt impact testing. Physiol Res. 2007;56(Suppl 1):S61–8.

Bayraktar HH, Morgan EF, Niebur GL, Morris GE, Wong EK, Keaveny TM. Comparison of the elastic and yield properties of human femoral trabecular and cortical bone tissue. J Biomech. 2004;37:27–35.

Menczel JD, Judovits L, Prime RB, Bair HE, Reading M, Swier S. Differential scanning calorimetry (DSC). In: Menczel JD, Prime RB, editors. Thermal analysis of polymers: fundamentals and applications. New Jersey: Wiley; 2009. p. 7–239.

Lebourg M, Anton JS, Gomez Ribelles JL. Porous membranes of PLLA–PCL blend for tissue engineering applications. Eur Polym J. 2008;44:2207–18.

Tracz A, Kucinska I, Jeszka JK. Unusual crystallization of polyethylene at melt/atomically flat interface: lamellar thickening growth under normal pressure. Polymer. 2006;47:7251–8.

Acknowledgments

The authors acknowledge the Texas Tech University Imaging Center, Department of Biological Sciences at Texas Tech University for use of the Hitachi S-4300SE/N (NSF MRI 04-511).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Allaf, R.M., Rivero, I.V. Fabrication and characterization of interconnected porous biodegradable poly(ε-caprolactone) load bearing scaffolds. J Mater Sci: Mater Med 22, 1843–1853 (2011). https://doi.org/10.1007/s10856-011-4367-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4367-7