Abstract

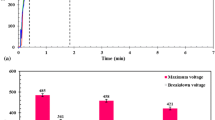

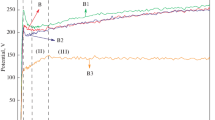

Laser surface modification of Ti–6Al–4V with an existing calcium phosphate coating has been conducted to enhance the surface properties. The electrochemical and mechanical behaviors of calcium phosphate deposited on a Ti–6Al–4V surface and remelted using a Nd:YAG laser at varying laser power densities (25–50 W/mm2) have been studied and the results are presented. The electrochemical properties of the modified surfaces in Ringer’s physiological solution were evaluated by employing both potentiodynamic polarization and electrochemical impedance spectroscopy (EIS) methods. The potentiodynamic polarizations showed an increase in the passive current density of Ti–6Al–4V after laser modification at power densities up to 35 W/mm2, after which it exhibited a decrease. A reduction in the passive current density (by more than an order) was observed with an increase in the laser power density from 25 to 50 W/mm2. EIS studies at the open circuit potential (OCP) and in the passive region at 1.19 V showed that the polarization resistance increased from 8.274 × 103 to 4.38 × 105 Ω cm2 with increasing laser power densities. However, the magnitudes remain lower than that of the untreated Ti–6Al–4V at OCP. The average hardness and modulus of the laser treated Ti–6Al–4V, evaluated by the nanoindentation method, were determined to be 5.4–6.5 GPa (with scatter <±0.976 GPa) and 124–155 GPa (with scatter <±13 GPa) respectively. The corresponding hardness and modulus of untreated Ti–6Al–4V were ~4.1 (±0.62) and ~148 (±7) GPa respectively. Laser processing at power densities >35 W/mm2 enhanced the surface properties (as passive current density is reduced) so that the materials may be suitable for the biomedical applications.

Similar content being viewed by others

References

Kazutaka So, Shunsuke Fujibayashi, Masashi Neo, Yukiko Anan, Tetsuro Ogawa, Tadashi Kokubo, Takashi Nakamura. Accelerated degradation and improved bone-bonding ability of hydroxyapatite ceramics by the addition of glass. Biomaterials. 2006;27(27):4738–44.

De With G, Van Dijk HJA, Hattu N, Prijs K. Preparation, microstructure and mechanical properties of dense polycrystalline hydroxyapatite. J Mater Sci. 1981;16:1592–8.

Xue WA, Tao S, Liu X, Zheng XB, Ding C. In vivo evaluation of plasma sprayed hydroxyapatite coatings having different crystallinity. Biomaterials. 2004;25:415–21.

Weng JB, Liu XG, Li XD, Zhang XD. Intrinsic factors of apatite influencing its amorphization during plasma spray coating. Biomaterials. 1995;16:39–44.

Cheang PC, Khor KA. Addressing processing problems associated with plasma spraying of hydroxyapatite coatings. Biomaterials. 1996;17:537–44.

Wolke JGC, Vander Waerden JPCM, Groot KD, Jansen JA. Stability of radiofrequency magnetron sputtered calcium phosphate coatings under cyclically loaded conditions. Biomaterials. 1997;18:483–8.

Ding SJ. Properties and immersion behavior of magnetron-sputtered multi-layered hydroxyapatite/titanium composite coatings. Biomaterials. 2003;24:4233–8.

Wang CK, Chern Lin JH, Ju CP, Ong HC, Chang RPH. Structural characterization of pulsed laser-deposited hydroxyapatite film on titanium substrate. Biomaterials. 1997;18:1331–8.

Bao Q, Chen C, Wang D, Ji Q, Lei T. Pulsed laser deposition and its current research status in preparing hydroxyapatite thin films. Appl Surf Sci. 2005;252:1538–44.

Narayanan R, Seshadri SK, Kwon TY, Kim KH. Electrochemical nano-grained calcium phosphate coatings on Ti–6Al–4V for biomaterial applications. Scr Mater. 2007;56:229–32.

Sena LAD, Andrade MCD, Rossi AM, Almeida GSC. Hydroxyapatite deposition by electrophoresis on titanium sheets with different surface finishing. J Biomed Mater Res. 2002;60:1–7.

Kuo MC, Yen SK. The process of electrochemical deposited hydroxyapatite coatings on biomedical titanium at room temperature. Mater Sci Eng C. 2002;20:153–60.

Changkook You, In-Sung Yeo, Myung-Duk Kim, Tae-Kwan Eom, Jae-Yeol Lee, Sukyoung Kim. Characterization and in vivo evaluation of calcium phosphate coated cp-titanium by dip-spin method. Curr Appl Phys. 2005;5:501–6.

Poser RD, Magee FP, Kay JF, Hedley AK. In vivo characterization of hydroxyapatite coatings. In: Birmingham AL, editors. Transactions of the 16th annual meeting of the society for biomaterials, vol. 13. Birmingham, Alabama; 1990. p. 170.

Garcia F, Arias JL, Mayor B, Pou J, Rehman I, Knowles J. Effect of heat treatment on pulsed laser deposited amorphous calcium phosphate coatings. J Biomed. Res. (Appl. Biomater.). 1998;43:69–76.

Watson CJ, Ogden AR, Tinsley D, Russel JL, Davidson EM. A 3–6 year study of overdenture supported by hydroxyapatite-coated endosseous dental implants. Int J Prosthodontics. 1998;11:610–9.

Achariya Rakngarm, Yoshiharu Mutoh. Electrochemical depositions of calcium phosphate film on commercial pure titanium and Ti–6Al–4V in two types of electrolyte at room temperature. Mater Sci Eng C. 2009;29(1):275–83.

De Groot K, Geesink R, Klein CPAT, Serekian P. Plasma sprayed coatings of hydroxylapatite. J Biomed Mater Res. 1987;21:1375–81.

Geesink RGT, De Groot K, Klein CPAT. Chemical implant fixation using hydroxyl-apatite coatings. The development of a human total hip prosthesis for chemical fixation to bone using hydroxyl-apatite coatings on titanium substrates. Clin Orthop Relat Res. 1987;225:147–70.

Mangal Roy, Vamsi Krishna B, Amit Bandopadhyay, Susmita Bose. Laser processing of bioactive tricalcium phosphate coating on titanium for load-bearing implants. Acta Biomater. 2008;4:324–33.

Zhu Weidong, Liu Qibin, Zheng Min, Xudong Wang. Biocompatibility of a functionally graded bioceramic coating made by wide-band laser cladding. J Biomed Mater Res A. 2008;87:429–33.

Kurella A, Dahotre NB. Laser induced hierarchical calcium phosphate structures. Acta Biomater. 2006;2:677–83.

Raghuvir Singh, Kurella A, Dahotre NB. Laser surface modification of Ti–6Al–4V: wear and corrosion characterization in simulated biofluid. J Biomater Appl. 2006;21:49–73.

Raghuvir Singh, Chowdhury SG, Tiwari SK, Dahotre NB. Laser surface processing of Ti–6Al–4V in gaseous nitrogen:corrosion performance in physiological solution. J Mater Sci: Mater Med. 2008;19:1363–9.

Kurella AK, Hu MZ, Dahotre NB. Effect of microstructural evolution on wettability of laser coated calcium phosphate on titanium alloy. Mater Sci Eng C. 2008;28:1560–4.

Sneddon IN. The relation between load and penetration in the axis symmetric Boussinesq problem for a punch of arbitrary profile. Int J Eng Sci. 1965;3:47–57.

Lusquiños F, De Carlos A, Pou J, Arias JL, Boutinguiza M, León B, Pérez-Amor M, Driessens FCM, Hing K, Gibson I, Best S, Bonfield W. Calcium phosphate coatings obtained by Nd:YAG laser cladding: physicochemical and biologic properties. J Biomed Mater Res A. 2003;64:630–7.

Cheng GJ, Pirzada D, Cai M, Mohanty P, Bandopadhyay A. Bioceramic coating of hydroxyapatite on titanium substrate with Nd-YAG laser. Mater Sci Eng C. 2005;25(4):541–7.

Ohtsu N, Sato Kenji, Yanagawa Aya, Saito Kesami, Imai Yoshio, Kohgo Takao, Yokoyama Atsuro, Asami Katsuhiko, Hanawa Takao. CaTiO3 coating on titanium for biomaterial application—optimum thickness and tissue response. J Biomed Mater Res A. 2007;82A(2):304–15.

Kim CS, Shin KY, Hwang KE, Jung MY, Lee DH. Precipitation behavior of titanium phosphide surfaces obtained from heat treated Ti–6Al–4V buried in hydroxyapatite paste. Ann Transplant. 2004;9:43–7.

Ohtsu N, Sato K, Saito K, Hanawa T, Asami K. Evaluation of degradability of CaTiO3 thin films in simulated body fluids. Mater Trans. 2004;45(5):1778–81.

Fontana MG. Corrosion engineering. Singapore: McGraw Hill Book Company; 1986. p. 460–469.

Fontana MG. Corrosion engineering. Singapore: McGraw Hill Book Company; 1986. p. 64–70.

Nikita Zaveri, Manas Mahapatra, Andrew Deceuster, Yun Peng, Leijun Li, Anhong Zhou. Corrosion resistance of pulsed laser-treated Ti–6Al–4V implant in simulated biofluids. Electrochim Acta. 2008;53:5022–32.

Liquinos F, Pou J, Boutinguiza M, Quintero F, Soto R, Leon B, Perez-Amor M. Main characteristics of calcium phosphate coatings obtained by laser cladding. Appl Surf Sci. 2005;247(1–4):486–92.

Steen WM. Industrial laser annual handbook. Tulsa: Penn Well Books; 1986. p. 158.

Jarcho M. Calcium phosphate ceramics as hard tissue prosthetics. Clin Orthop Relat Res. 1981;157:259–78.

Valereto ICL, Wolynec S, Ramires I, Guastaldi AC, Costa I. Electrochemical impedance spectroscopy characterization of passive film formed on implant Ti–6Al–7Nb alloy in Hank’s solution. J Mater Sci: Mater Med. 2004;15:55–9.

Metikos-Hukovic M, Kwokal A, Piljac J. The influence of niobium and vanadium on passivity of titanium-based implants in physiological solution. Biomaterials. 2003;24:3765–75.

Niinomi M. Recent research and development in titanium alloys for biomedical applications and healthcare goods. Adv Mater. 2003;4:445–54.

Singh Raghuvir, Dahotre NB. Corrosion degradation and prevention by surface modification of biometallic materials. J Mater Sci: Mater Med. 2007;18:725–51.

Bundinsiki KG. Tribological properties of titanium alloys. Wear. 1991;151:203–17.

Yongqing Fu, Loh NL, Batchelor AW, Liu D, Zhu X, Jaiwen He, Kewei Xu. Improvement in fretting wear and fatigue resistance of Ti–6Al–4V by application of several surface treatments and coatings. Surf Coat Technol. 1998;106(2–3):193–7.

Acknowledgments

The authors are thankful to the Director, National Metallurgical Laboratory, Jamshedpur, Council of Scientific & Industrial Research for granting permission to publish this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, R., Tiwari, S.K., Mishra, S.K. et al. Electrochemical and mechanical behavior of laser processed Ti–6Al–4V surface in Ringer’s physiological solution. J Mater Sci: Mater Med 22, 1787–1796 (2011). https://doi.org/10.1007/s10856-011-4362-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4362-z