Abstract

The corrosion behaviour of heat treated Ti–13Zr–13Nb (TZN) and Ti–13Zr–13Nb–0.5B (TZNB) alloys in Hank’s solution has been investigated. The microstructure of the heat treated TZN alloy consisted of α, β or martensite. Addition of boron to TZN alloy led to the formation of dispersed TiB particles and modification of microstructure. In general, the furnace cooled TZN sample showed lower corrosion potential (Ecorr) than the air cooled sample. Aging of water quenched samples decreased the Ecorr value. The passive current density of TZN samples varied within a narrow range. Presence of boron in TZN alloy decreased the corrosion potential and substantially increased the passive current density. Results showed that boron deteriorated the corrosion resistance of TZN alloy.

Similar content being viewed by others

References

López MF, Gulirrez A, Jimnez JA. Surface characterization of new non-toxic titanium alloys for use as biomaterials. Surf Sci. 2001;482–485:300–5.

Mändl S, Rader R, Thorwarth G, Krause D, Zeilhofer HF, Horch HH, Rauschenbach B. Investigation on plasma immersion ion implantation treated medical implants. Biomol Eng. 2002;19:129–32.

López MF, Jimnez JA, Gutiérrez A. Corrosion study of surface-modified vanadium-free titanium alloys. Electrochim Acta. 2003;48:1395–401.

Okazaki Y, Tateishi T, Ito Y. Corrosion resistance of implants alloys in pseudo physiological solution and role of alloying elements in passive films. Mater Trans JIM. 1997;38:78–84.

Leinenbach C, Eifler D. Fatigue and cycle deformation behaviour of surface-modified titanium alloys in simulated physiological media. Biomaterials. 2006;27:1200–8.

Geetha M, Mudali UK, Gogia AK, Asokamani R, Raj BD. Influence of microstructure and alloying elements on corrosion behavior of Ti–13Nb–13Zr alloy. Corros Sci. 2004;46:877–92.

Aparicio C, Gil FJ, Fonseca C, Barbosa M, Planell JA. Corrosion behaviour of commercially pure titanium shot blasted with different materials and sizes of shot particles for dental implant applications. Biomaterials. 2003;24:263–73.

Okazaki Y, Rao S, Ito Y, Tateishi T. Corrosion resistance, mechanical properties, corrosion fatigue strength and cytocompatibility of new Ti alloys without Al and V. Biomaterials. 1998;19:1197–215.

Manivasagam G, Mudali UK, Asokamani R, Raj B. Corrosion and microstructural aspects of titanium and its alloys as orthopaedic devices. Corros Rev. 2003;21:125–59.

Yu SY, Scully JR. Corrosion and passivity of Ti–13%Nb–13%Zr in comparison to other biomedical implant alloys. Corrosion. 1997;53:965–76.

Okazaki Y. A new Ti–15Zr–4Nb–Ta alloy for medical applications. Curr Opi Sol State Mat Sci. 2001;5:45–53.

Khan MA, Williams RL, Williams DF. In vitro corrosion and wear of titanium alloys in the biological environment. Biomaterials. 1996;17:2117–26.

Khan MA, Williams RL, Williams DF. The corrosion behaviour of Ti–6Al-4 V, Ti–6Al–7Nb and Ti–13Zr–13Nb in protein solutions. Biomaterials. 1999;20:631–7.

Oliveira NTC, Ferreira EA, Duarte LT, Biaggio SR, Rocha-Filho RC, Bocchi N. Corrosion resistance of anodic oxides on the Ti–50Zr and Ti–13Zr–13Nb alloys. Electrochim Acta. 2006;51:2068–75.

Cai Z, Shafer T, Watanabe I, Nunn ME, Okabe T. Electrochemical characterization of cast titanium alloys. Biomaterials. 2003;24:213–8.

Niinomi M, Kuroda D, Fukunaga KI, Morinaga M, Kato Y, Yashiro T, Suzuki A. Corrosion wear fracture of new β type biomedical titanium alloys. Mater Sci Eng A. 1999;263:193–9.

Williams DF. Titanium for medical applications. In: Brunette DM, Tengvall P, Texfor M, Thomsen P, editors. Titanium in medicine. New York: Springer; 2001. p. 13–24.

Kobayashi E, Doi H, Yoneyama T, Hamanaka H, Gimson IR, Best SM, Shelton JC, Bonfield W. Influence of aging heat treatment on mechanical properties of biomedical Ti–Zr based ternary alloys containing niobium. J Mater Sci Mater Med. 1998;9:625–30.

Samuel S, Nag S, Scharf TW, Banerjee R. Wear resistance of laser-deposited boride reinforced Ti–Nb–Zr–Ta alloy composites for orthopedic implants. Mater Sci Eng C. 2008;28:414–20.

Zhang X, Lu W, Zhang D, Wu R. In situ technique for synthesizing (TiB + TiC)/Ti composites. Scripta Mater. 1999;41:39–46.

Chen W, Boehlert CJ. The elevated-temperature fatigue behavior of boron-modified Ti–6Al-4 V (wt%) castings. Mater Sci Eng A. 2008;494:132–8.

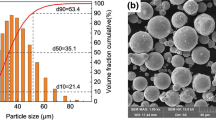

Majumdar P. PhD Thesis. IIT Kharagpur, India. 2009.

Majumdar P, Singh SB, Chakraborty M. Wear response of heat-treated Ti–13Zr–13Nb alloy in dry condition and simulated body fluid. Wear. 2008;264:1015–25.

Semlitsch MF, Weber H, Streicher RM, Schön R. Joint replacement components made of hot-forged and surface-treated Ti–6Al–7Nb alloy. Biomaterials. 1992;13:781–8.

Long M, Rack HJ. Titanium alloys in total joint replacement—a materials science perspective. Biomaterials. 1998;19:1621–39.

Raman V, Tamilselvi S, Nanjundan S, Rajendran N. Electrochemical behaviour of titanium and titanium alloy in artificial saliva. Trends Biomater Artif Organs. 2005;18:137–40.

Wayman CM, Bhadeshia HKDH. Phase transformations, nondifusive. In: Cahn RW, Haasen P, editors. Physical metallurgy. Amsterdam: Elsevier Science Publishers; 1996. p. 1507–54.

Ahmed T, Rack HJ. Martensitic transformations in Ti-(16–26 at%) Nb Alloys. J Mater Sci. 1996;31:4267–76.

Bernard S, Covino Jr, Alman DE. Corrosion of titanium matrix composites, Report No.: DOE/ARC-2002-011, Albany Research Center, U.S. Department of Energy, Albany, OR USA.

Tamirisakandala S, Bhat RB, Tiley JS, Miracle DB. Grain refinement of cast titanium alloys via trace boron addition. J Mater Eng Perform. 2005;53:1421–6.

Cherukuri B, Srinivasan R, Tamirisakandala S, Miracle DB. The influence of trace boron addition on grain growth kinetics of the beta phase in the beta titanium alloy Ti–15Mo–2.6Nb–3Al–0.2Si. Scripta Mater. 2009;60:496–9.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Majumdar, P., Singh, S.B., Chatterjee, U.K. et al. Corrosion behaviour of heat treated boron free and boron containing Ti–13Zr–13Nb (wt%) alloy in simulated body fluid. J Mater Sci: Mater Med 22, 797–807 (2011). https://doi.org/10.1007/s10856-011-4282-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4282-y