Abstract

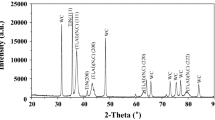

In view of the potential engineering applications requiring machinability and wear resistance, the present work focuses to evaluate hardness property and to understand the damage behavior of some selected glass–ceramics having different crystal morphologies with SiO2–MgO–Al2O3–K2O–B2O3–F composition, using static micro-indentation tests as well as dynamic scratch tests, respectively. Vickers hardness of up to 5.5 GPa has been measured in glass–ceramics containing plate like mica crystals. Scratch tests at a high load of 50 N in artificial saliva were carried out in order to simulate the crack–microstructure interaction during real-time abrasion wear and machining operation. The experimental observations indicate that the novel “spherulitic-dendritic” shaped crystals, similar to the plate like crystals, have the potential to hinder the scratching induced crack propagation. In particular, such potential of the ‘spherulitic-dendritic’ crystals become more effective due to the larger interfacial area with the glass matrix as well as the dendritic structure of each mica plate, which helps in crack deflection and crack blunting, to a larger extent. While modest damage tolerant behavior is observed in case of ‘spherulitic-dendritic’ crystal containing material, severe brittle fracture of plate like crystals were noted, when both were scratched at 50 N load.

Similar content being viewed by others

Notes

FEI QUANTA 200, The Netherlands.

Isodebyeflex 2002, USA.

Carl Zeiss Jena, Germany.

TR 101, Ducom, Bangalore, India.

PC5500, Eutech Instruments, USA.

References

Vogel W, Höland W, Kaumann K. Development of machinable bioactive glass–ceramics for medical uses. J Non-Cryst Solids. 1986;80:34–51.

Chaudhry MA, Jonscher AK. High-temperature dielectric properties of ruby mica perpendicular to the cleavage planes. J Mater Sci. 1988;23:208–16.

Holand W, Vogel W. Machineable and phosphate glass ceramics. In: Hench LL, Wilson J, editors. Introduction to bioceramics. Singapore: World Scientific; 1993. pp. 125–38.

Holand W, Beall G. Glass–ceramic technology. Westerville, OH: The American Ceramic Society; 2002.

Cheng K, Wan J, Liang K. Crystallization of R2O–MgO–Al2O3–B2O3–SiO2–F (R = K+, Na+) glasses with different fluorine sources. Mater Lett. 2001;47:1–6.

Hoche T, Habelitz S, Avramov I. Crystal morphology engineering in SiO2–Al2O3–MgO–K2O–Na2O–F− mica glass–ceramics. Acta Mater. 1998;PII:S1359–6454; 00424–8.

Gebhardt A, Hoche T, Carl G, Khodos II. TEM study on the origin of cabbage-shaped mica crystal aggregates in machinable glass–ceramics. Acta Mater. 1999;47(17):4427–34.

Quinn JB, Sundar V, Lloyd IK. Influence of microstructure and chemistry on the fracture toughness of dental ceramics. Dent Mater. 2003;19:603–11.

Höche T, Habelitz S, Khoodos II. Origin of unusual fluorophlogopite morphology in mica glass–ceramics of the system SiO2–Al2O3–MgO–K2O–Na2O–F2. J Cryst Growth. 1998;192:185–95.

Boccaccini AR. Machinability and brittleness of glass–ceramics. J Mater Process Technol. 1997;65:302–4.

Ma XP, Li GX, Shen L, Jin ZH. Ductile-mode material removal of a mica–glass–ceramic. J Am Ceram Soc. 2003;86(6):1040–2.

Lawn BR, Padture NP, Cai H, Guiberteau F. Making ceramics ‘ductile’. Science. 1994;263:1114–6.

Baik DS, No KS, Chun JS, Cho HY. Effect of the aspect ratio of mica crystals and crystallinity on the microhardness and machinability of mica glass–ceramics. J Mater Process Technol. 1997;67:50–4.

Grossman DG. Machinable glass–ceramics based on tetrasilicic mica. J Am Ceram Soc. 1972;55(9):446–9.

Xu HK, Jahanmir S. Scratching and grinding of a machinable glass–ceramic with weak interfaces and rising T-curve. J Am Ceram Soc. 1995;78:497–500.

Flanders LA, Quinn JB, Wilson OC Jr, Lloyd IK. Scratch hardness and chipping of dental ceramics under different environments. Dent Mater. 2003;19:716–24.

Roy S, Basu B. On the development of two characteristically different crystal morphology in SiO2–MgO–Al2O3–K2O–B2O3–F glass–ceramic system. J Mater Sci: Mater Med. 2008;20(1):51–66.

Roy S, Basu B. In vitro dissolution behavior of SiO2–MgO–Al2O3–K2O–B2O3–F glass–ceramic system. J Mater Sci: Mater Med. 2008;19:3123–33.

Roy S. Microstructure development and in-vitro properties of Macor Glass–ceramic, M. Tech Thesis, IIT Kanpur, India, May 2005.

Guedes A, Pinto AMP, Vieira M, Viana F. Multilayered interface in Ti:Macor® machinable glass–ceramic joints. Mater Sci Eng A. 2001;301:118–24.

Wange P, Höche T, Rüssel C, Schnapp JD. Microstructure-property relationship in high-strength MgO–Al2O3–SiO2–TiO2 glass–ceramics. J Non-Cryst Solids. 2002;298:137–45.

Karamanov A, Pelino M. Evaluation of the degree of crystallization in glass–ceramics by density measurements. J Eur Ceram Soc. 1999;19:649-54.

Roy S, Basu B. Mechanical and tribological characterization of human tooth. Mater Charact. 2008;59:747–56.

Li H, Zhou ZR. Wear behaviour of human teeth in dry and artificial saliva conditions. Wear. 2002;249:980–4.

Uhlmann DR. Crystal growth in glass-forming systems—a review. In: Hench LL, Freiman FW, editors. Advances in nucleation and crystallization in glasses, special publication 5. Columbus, OH: American Ceramic Society; 1971. pp. 91–115.

Cripps ACF, Lawn BR. Indentation stress–strain curves for ‘quasi-ductile’ ceramics. Acta Mater. 1996;44(2):519–27.

Peterson IM, Wuttiphan S, Lawn BR, Chyung K. Role of microstructure on contact damage and strength degradation of micaceous glass–ceramic. Dent Mater. 1998;14(1):80–9.

Saraswati V, Raoot S. Machinable mica-based glass–ceramic. J Mater Sci. 1992;27:429–32.

Henry J, Hill RG. The influence of lithia content on the properties of fluorphlogopite glass–ceramics. II. Microstructure hardness and machinability. J Non-Cryst Solids. 2003;319:13–30.

Taruta S, Mukoyama K, Suzuki SS, Kitajima K, Takusagawa N. Crystallization process and some properties of calcium mica–apatite glass–ceramics. J Non-Cryst Solids. 2001;296:201–11.

Davis JB, Marshall DB, Housley RM, Morgan PED. Machinable ceramics containing rare-earth phosphates. J Am Ceram Soc. 1998;81:2169–75.

Goswami M, Sarkar A, Mirza T, Shrikhande VK, Sangeeta, Gurumurthy KR, et al. Study of some thermal and mechanical properties of magnesium aluminium silicate glass–ceramic. Ceram Int. 2002;28:585–92.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roy, S., Basu, B. Hardness properties and microscopic investigation of crack–crystal interaction in SiO2–MgO–Al2O3–K2O–B2O3–F glass ceramic system. J Mater Sci: Mater Med 21, 109–122 (2010). https://doi.org/10.1007/s10856-009-3853-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-009-3853-7