Abstract

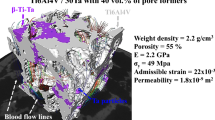

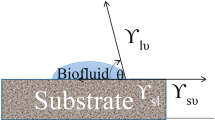

Open-cell porous Ti with a porosity ranging from 35 to 84% was successfully manufactured by sintering titanium fibres. The microstructure of the porous titanium was observed by SEM and the compressive mechanical properties were tested. By adjusting the spiral structure of the porous titanium, the pore size can be controlled in a range of 150–600 μm. With the increasing of the porosity, compressive yield strength and modulus decrease as predicated. However, high mechanical properties were still obtained at a medium porosity, e.g. the compressive yield strength and the modulus are as high as 100–200 MPa and 3.5–4.2 GPa, respectively, when the porosity is in the range of 50–70%. It was suggested that the porous titanium be strong enough to resist handing during implantation and in vivo loading. It is expected to be used as biocompatible implant, because their interconnected porous structures permit bone tissues ingrowth and the body fluids transportation.

Similar content being viewed by others

References

F. LI, Q. L. FENG, F. Z. CUI, H. D. LI and H. SCHUBERT, Surf. Coat. Technol. 154 (2002) 88

K. ANSELME, Biomaterials 2000, 21(7):667

S. FUJIBAYASHI, M. NEO, H. M. KIM, T. KOKUBO and T. NAKAMURA, Biomaterials 25 (2004) 443

H. P. DEGISCHER and B. KRISZT, in “Handbook of Cellular Metals: Production, Processing, Applications” (Wiley-VCH, 2002) p.1

L. J. GIBSON and M.F. ASHBY, in “Cellular Solids: Structure and Properties”, 2nd edn. (Cambridge University Press, 1997) pp. 1

S. F. HULBERT, S. J MORRISON and J. J. KLAWITTER, J. Biomed. Mater. Res. 6 (1972) 347

T. J. FLATLEY, K. L. LYNCH and M. BENSON, Clin. Orthop. 179 (1983) 246

N. TAMAI, A. MYOUI, T. TOMITA, T. NAKASE, J. TANAKA, T. OCHI and H. YOSHIKAWA, J. Biomed. Mater. Res. 59 (2002) 110

H. LI, Q. F. YU, B. ZHANG, H. WANG, H. S. FAN and X. D. ZHANG, Rare Metal Mat. Eng. 35 (2006) 154

O. ANDERSEN, U. WAAG, L. SCHNEIDER, G. STEPHANI and B. KIEBACK, Adv. Eng. Mater. 2 (2000) 192

M. TAKEMOTO, S. FUJIBAYASHI, M. NEO, J. SUZUKI, T. KOKUBO and T. NAKAMURA, Biomaterials 26 (2005) 6014

J. BANHART, Prog. Mater. Sci. 46 (2001) 559

C. CHEN, T. J. LU and N. A. FLECK, J. Mech. Phys. Sol. 47 (1999) 2235

G. SCHAFFNER, X. D. E. GUO, M. J. SILVA and L. J. GIBSON, Int. J. Mech. Sci. 42 (2000) 645

ISO 2738, in “Permeable Sintered Metal Materials—Determination of Density, Oil Content and Open Porosity” (1987)

Y. B. P. KWAN and J. R. ALCOCK, J. Mater. Sci. 37 (2002) 2557

J. D. BOBYN, C. A. ENGH and R. M. PILLIAR, in “Quantitative Characterization and Performance of Porous Implants for Hard Tissue Applications”, Edited by: J. E. LEMONS (ASTM, STP 953, 1987) p.185

B. WANG, J. R. KLEPACZKO, G. LU and L. X. KONG, J. Mater. Process. Technol. 113 (2001) 574

E. L. ZHANG and B. WANG, Int. J. Mech. Sci. 47 (2005) 744

C. E. WEN, Y. YAMADA, K. SHIMOJIMA, Y. CHINO, T. ASAHINA and M. MABUCHI, J. Mater. Sci.: Mater. M. 13 (2002) 397

C. E. WEN, M. MABUCHI, Y. YAMADA, K. SHIMOJIMA, Y. CHINO and T. ASAHINA, Scripta Mater. 45 (2001) 1147

M. BRAM, C. STILLER, H. P. BUCHKREMER and D. STÖVER, in “Metal Foams and Porous Metal Structures”, Edited by J. Banhart, M. F. Ashby and N.A.Fleck (MIT Verlag, 1999) p. 197

S. H. LEE, J. W. CHOI, W. Y. LEUNG and T. J. MOON, Powder Metal. 42 (1999) 41

Acknowledgements

One of authors (Erlin Zhang) would like to acknowledge the financial supports from Institute of Metal Research (IMR) and Chinese Academy of Sciences (CAS) China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zou, C., Zhang, E., Li, M. et al. Preparation, microstructure and mechanical properties of porous titanium sintered by Ti fibres. J Mater Sci: Mater Med 19, 401–405 (2008). https://doi.org/10.1007/s10856-006-0103-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-006-0103-0