Abstract

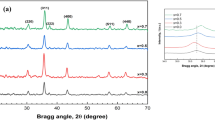

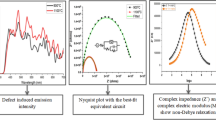

In this paper, we report the preparation of nano-crystalline thin films of nickel aluminate spinel ferrite having the chemical formula NiFe2−xAlxO4, where Al3+ varies from 0.0 to 0.4 with rise in 0.1, using the well-known spray pyrolysis deposition method. The thin films were grown and deposited on ultrasonically clean glass substrate. The X-ray diffraction pattern show orientation of various is diffraction peaks at (220), (311) (222), (400), (422), (511), and (440). The presence of this diffraction peak suggests the formation of single-phase compound as there are no extra diffraction peaks in the XRD pattern other than cubic spinel phase. The crystallite size deduced from the Debye–Scherrer equation varies in the range 19–14 nm. The Lattice parameter found to decrease with doping of Al3+ ions. FTIR spectra show the absorbance bands are close to the 400 cm−1 and 600 cm−1 wave number which are attributed to stretching vibrations of metal–oxygen bond. The presence of five active modes in Raman spectra confirm the ferrimagnetic spinel structure of the thin film. Field emission scanning electron microscopy (FESEM) shows the spherical grain morphology with some agglomeration. Energy-dispersive X-ray analysis (EDAX) spectra show the presence NiFe2−xAlxO4 elements in stoichiometric proportion. The ohmic nature of the prepared thin film was confirmed through I–V characteristics. The band gap energy estimated through UV–visible technique varies in the range of 2.05–1.14 eV indicating the semiconducting behavior of the prepared thin films. The obtained results are useful for opto-electronic devices.

Similar content being viewed by others

Data availability

The research data generated and analyzed during the current study are available from the corresponding author upon reasonable request.

References

I. Dumitru, O.F. Caltun, Ferrite Nanostructured Magnetic Materials (Elsevier, Amsterdam, 2023). https://doi.org/10.1016/B978-0-12-823717-5.00017-6

N. Yasmin, S. Abdulsatar, M. Hashim, M. Zahid, S.G. Fatima, A. Kalsoom, M.N. Shiq, I. Inam, M. Safdar, M. Mirza, J. Magn. Magn. Mater. (2019). https://doi.org/10.1016/j.jmmm.2018.10.076

X. Han, J. Li, H. Wu, K. Sun, Y. Chen, L. Jia, H. Zhang, P. Zhang, C. Wu, J. Magn. Magn. Mater. (2023). https://doi.org/10.1016/j.jmmm.2023.170512

M. Sugimoto, J. Am. Ceram. Soc. (1999). https://doi.org/10.1111/j.1551-2916.1999.tb20058.x

M.N. Akhtar, S. Makhdoom, M.A. Baqir, M. Yousaf, M.A. Khan, K.M. Batoo, S. Hussain, Ceram. Int. (2022). https://doi.org/10.1016/j.ceramint.2022.06.208

W. Zhu, L. Wang, R. Zhao, J. Ren, G. Lua, Y. Wang, Nanoscale (2011). https://doi.org/10.1039/C1NR10274E

O.D. Dastjerdi, H. Shokrollahi, S. Mirshekari, Inorg. Chem. Commun. (2023). https://doi.org/10.1016/j.inoche.2023.110797

O. Caltun, H. Chiriac, N. Lupu, I. Dumitru, B.P. Rao, J. Optoelectron. Adv. Mater. (2007). https://www.researchgate.net/profile/Ovidiu-Caltun/publication/228856465_High_magnetostrictive_doped_cobalt_ferrite/links/0fcfd50e53ed93d1d9000000/High-magnetostrictive-doped-cobalt-ferrite.pdf

S. Manori, A. Manori, R.K. Shukla, Engineered Ferrites and Their Applications (Springer, Singapore, 2023). https://doi.org/10.1007/978-981-99-2583-4_10

M. Aadil, A.G. Takib, S. Zulfiqar, A. Rahmane, M. Shahidf, M.F. Warsif, Z. Ahmad, A.A. Alothmanh, S. Mohammad, RSC Adv. (2023). https://doi.org/10.1039/D3RA05290G

S. Li, Y. Yang, H. Zheng, Y. Zheng, C.-S. He, B. Lai, J. Ma, J. Nan, Water Res. (2022). https://doi.org/10.1016/j.watres.2022.119176

G. Katoch, J. Prakash, R. Jasrotia, A. Verma, R. Verma, S. Kumari, T. Ahmad, S.K. Godara, J. Ahmed, A. Kandwal, M. Fazil, P.K. Maji, S. Kumar, G. Kumar, J. Water Process Eng. (2023). https://doi.org/10.1016/j.jwpe.2023.103726

C. Wang, G. Sui, D. Guo, J. Li, Z. Luo, D.-F. Chai, M. Qi, Int. J. Hydrogen Energy (2022). https://doi.org/10.1016/j.ijhydene.2022.05.185

J.H. Kim, H.E. Kim, J.H. Kim, J.S. Lee, J. Mater. Chem. A (2020). https://doi.org/10.1039/D0TA01554G

Y. Zhang, Y. Yang, C. Chen, D. Chen, Y. Meng, Ceram. Int. (2023). https://doi.org/10.1016/j.ceramint.2023.08.276

M.N. Akhtar, S. Makhdoom, M.S. Nazir, M. Yousaf, M.A. Khan, Magnetic Nanoferrites and Their Composites (Elsevier, Amsterdam, 2023). https://doi.org/10.1016/B978-0-323-96115-8.00014-3

P. Priyadharshini, K. Pushpanathan, Chem. Phys. Impact (2023). https://doi.org/10.1016/j.chphi.2023.100201

A. Hajalilou, S.A. Mazlan, Appl. Phys. A (2016). https://doi.org/10.1007/s00339-016-0217-2

J. Ai, Z.Y. Shua, M. Hu, L. Cheng, S. Luo, W. Li, Z. Chen, L. Hu, Z. Zhou, Ceram. Int. (2023). https://doi.org/10.1016/j.ceramint.2023.04.119

M.A. Dar, Research Prospects in Natural Sciences (RPNS) (2023), https://journals.gctownship.edu.pk/index.php/rpns/article/view/58

L. Kumar, P. Kumar, M. Kar, Appl. Nanosci. (2013). https://doi.org/10.1007/s13204-012-0071-2

N. Sivakumar, A. Narayanasamy, J.-M. Greneche, R. Murugaraj, Y.S. Lee, J. Alloys Compd. (2010). https://doi.org/10.1016/j.jallcom.2010.05.125

F. Li, J. Liu, D.G. Evans, X. Duan, Chem. Mater. (2004). https://doi.org/10.1021/cm035248c

A.R. Chavan, J.S. Kounsalye, R.R. Chilwar, S.B. Kale, K.M. Jadhav, J. Alloys Compd. (2018). https://doi.org/10.1016/j.jallcom.2018.08.061

L. Krishnia, P. Thakur, A. Thakur, Synthesis and Applications of Nanoparticles (Springer, Singapore, 2022). https://doi.org/10.1007/978-981-16-6819-7_3

M. El Jouad, T. Garmim, A. Louardi, B. Hartiti, M. Monkade, S. Touhtouh, A. Hajjaji, Mater. Sci. Eng. B (2022). https://doi.org/10.1016/j.mseb.2022.116044

B. Kharat, V. Magar, S. Rathod, A.A. Chaudhari, V.B. Malode, Adv. Mater. Res. (2022). https://doi.org/10.4028/p-f41120

S.R. Sriram, S.R. Parne, N. Pothukanuri, S.R. Edla, J. Anal. Appl. Pyrol. (2022). https://doi.org/10.1016/j.jaap.2022.105527

B.C. Marupalli, A. Behera, S. Aich, Trans. Indian Inst. Met. (2021). https://doi.org/10.1007/s12666-021-02418-z

A. Faramawy, H. El Sayed, Nano Express (2023). https://doi.org/10.1088/2632-959X/ad0ee9

T. Dippong, D. Toloman, M.D. Lazar, I. Petean, Nanomaterials (2023). https://doi.org/10.3390/nano13243096

S. Nandy, K.H. Chae, Ferrite Nanostructured Magnetic Materials (Elsevier, Amsterdam, 2023). https://doi.org/10.1016/B978-0-12-823717-5.00021-8

M.M. Naik, H.S.B. Naik, G. Nagaraju, M. Vinuth, K. Vinu, S.K. Rashmi, J. Mater. Sci.: Mater. Electron. (2018). https://doi.org/10.1007/s10854-018-0174-y

S.B. Somvanshi, M.V. Khedkar, P.B. Kharat, K.M. Jadhav, Ceram. Int. (2020). https://doi.org/10.1016/j.ceramint.2019.12.097

R.T. Shannon, C.T. Prewitt, Struct. Sci. Cryst. Eng. Mater. (1969). https://doi.org/10.1107/S0567740869003220

R.T. Shannon, C. Prewitt, Struct. Sci. Cryst. Eng. Mater. (1970). https://doi.org/10.1107/S0567740870003576

A.R. Chavan, S.D. Birajdar, R.R. Chilwar, K.M. Jadhav, J. Alloys Compd. (2018). https://doi.org/10.1016/j.jallcom.2017.11.326

A. Raghavender, D. Pajic, K. Zadro, T. Milekovic, P.V. Rao, K.M. Jadhav, D. Ravinder, J. Magn. Magn. Mater. (2007). https://doi.org/10.1016/j.jmmm.2007.03.204

S.Z.H. Hashmi, M. Khalid, G. Mustafa, M.G.B. Ashiq, M. Younas, A. Quddus, H.S.M. Abd-Rabboh, T. Alshahrani, K. Naz, M.M. Javid, Mater. Chem. Phys. (2023). https://doi.org/10.1016/j.matchemphys.2023.127912

S. Das, S. Paikaray, I. Swain, S. Senapati, R. Naik, Surf. Interfaces (2023). https://doi.org/10.1016/j.surfin.2023.103395

S. Giri, P. Priyadarshini, D. Alagarasan, R. Ganesan, R. Naik, RSC Adv. (2023). https://doi.org/10.1039/D3RA03731B

D. Pawar, S.M. Pawar, P.S. Patil, S.S. Kolekar, J. Alloys Compd. (2011). https://doi.org/10.1016/j.jallcom.2010.12.079

D.D. Andhare, S.R. Patade, J.S. Kounsalye, K.M. Jadhav, Physica B (2020). https://doi.org/10.1016/j.physb.2020.412051

D.D. Andhare, S.R. Patade, S.A. Jadhav, S.B. Somvanshi, K.M. Jadhav, Appl. Phys. A (2021). https://doi.org/10.1007/s00339-021-04603-9

D. Alagarasan, S. Varadharajaperumal, R. Aadhavan, B. Shanmugavelu, R. Naik, Kh. Salunii, K. Haunsbhavi, M. Shkir, E.E.S. Massoud, R. Ganesan, Sens. Actuators A (2023). https://doi.org/10.1016/j.sna.2022.114065

R. Naik, A. Jain, R. Ganesan, K.S. Sangunni, Thin Solid Films (2012). https://doi.org/10.1016/j.tsf.2011.10.029

A. Henaish, B.I. Salem, T.M. Meaz, Y.A. Alibwaini, A.W. Ajlouni, O.M. Hemeda, E.A. Arrasheed, Opt. Mater. (2021). https://doi.org/10.1016/j.optmat.2021.111397

R. Panda, H. Rath, S.A. Khan, D. Alagarasan, U.P. Singh, N.C. Mishra, R. Naik, Surf. Interfaces (2023). https://doi.org/10.1016/j.surfin.2023.103081

Acknowledgements

Vikas U. Magar is thankful to MAHAJYOTI (Mahatma Phule Research and Training Institute, Nagpur) for providing financial support. The author is thankful to Director, Institute of Chemical Technology, Mumbai Marathwada Campus, Jalna, for providing Raman data.

Funding

Vikas U. Magar acknowledges financial support from Mahatma Jyotiba Phule Research and Training Institute (MAHAJYOTI), Maharashtra State in then form of Mahatma Jyotiba Phule Research Fellowship (MAHAJYOTI/2022/Ph.D.Fellow/1002 (1178)).

Author information

Authors and Affiliations

Contributions

Vikas U. Magar conceived and designed the research study, performed the experiments, analyzed the data, and wrote the manuscript. Sagar V. Rathod, Pratik Patil, and Smita More contributed to the supervision, experimental design, data analysis, and manuscript preparation. M.K. Babrekar assisted in data collection, interpretation, and critical revision of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests regarding the publication of this research manuscript.

Ethical approval

This research study was conducted in compliance with ethical standards.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Magar, V.U., Rathod, S.V., Patil, P.S. et al. Structural and optical properties of nickel aluminate spinel ferrite thin films prepared by spray pyrolysis technique. J Mater Sci: Mater Electron 35, 967 (2024). https://doi.org/10.1007/s10854-024-12705-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12705-2