Abstract

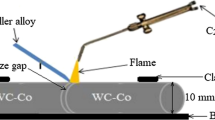

In this study, a Cu–Ti/Cu/BNi-2 composite filler was employed to braze Al2O3 ceramics and Kovar alloy, aiming to prevent excessive reaction between active Ti and Kovar alloy. The investigation focused on the effects of varying Cu interlayer thickness on microstructure and mechanical properties. The results show that the typical microstructure of the joint is Al2O3/Ti–O/Cu3Ti3O /Ti-rich + Cu(s, s)/Ni3Ti + TiB2/CrB + Ni(s, s)/Kovar alloy. Notably, when the thickness of the Cu layer was 100 μm, the joint strength significantly increased to 128 ± 7 MPa, which represented a remarkable 50.5% improvement compared to the Cu–Ti filler. This enhancement in joint strength can be attributed to the addition of Cu/BNi-2, effectively preventing direct contact between Ti and Kovar alloy, thereby inhibiting their reaction and reducing the formation of brittle Fe-Ti phases within the joint. At the same time, Cu foil also contributed to alleviating the residual stress of the joint. However, as the Cu foil thickness increased, the fracture of the Cu3Ti3O reaction layer worsened, resulting in weaker bonding with ceramics and a decrease in joint strength. The study also discussed the microstructure evolution of the Al2O3/Cu–Ti/Cu/BNi-2/Kovar joint. This study provided an idea for the application of Cu-based filler.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

B.B. Fan, J.K. Xu, H.C. Lei, L. Zhao, Di Z.P. An, Xie, Microstructure and mechanical properties of Al2O3/Cu joints brazed with Ag–Cu–Ti + Zn composite fillers. Ceram. Int. 48, 18551–18557 (2022)

Z.Q. Wang, C. Li, X.Q. Si, M.S. Zheng, L. Chen, Y.X. Huang, J.L. Qi, J. Cao, Microstructure and mechanical properties of Al2O3 ceramic joints achieved by Ag-SiO2 braze in air. Int. J. Appl. Ceram. Technol. 19, 508–513 (2022)

J.G. Bai, X.H. Yang, S.C. Xu, Y.G. Shi, J.F. Yang, Fabrication of highly dense Al2O3 ceramics. Scripta Mater. 68, 393–395 (2013)

W. Guo, T.S. Lin, P. He, T. Wang, Y.N. Wang, Microstructure evolution and mechanical properties of ZnAl2O4-reinforced Al2O3/Al2O3 joints brazed with a bismuth borate zinc glass. Mater. Des. 119, 303–310 (2017)

Y. Lu, M.X. Zhu, Q. Zhang, T. Hu, J. Wang, K.H. Zheng, Microstructure evolution and bonding strength of the Al2O3/Al2O3 interface brazed via Ni-Ti intermetallic phases. J. Eur. Ceram. Soc. 40, 1496–1504 (2020)

G.B. Niu, D.P. Wang, Z.W. Yang, Y. Wang, Microstructure and mechanical properties of Al2O3 ceramic and TiAl alloy joints brazed with Ag–Cu–Ti filler metal. Ceram. Int. 42, 6924–6934 (2016)

W.J. Li, W. Ji, Q.Q. Zhu, B.W. Fan, J. Zou, W.M. Wang, Z.Y. Fu, Heterogeneous material joining of sapphire and TC4 alloy with a functionally graded interface. Int. J. Appl. Ceram. Technol. 20, 1028–1036 (2023)

P.X. Li, Y.T. Yan, J. Ba, P.C. Wang, H.H. Wang, X.X. Wang, J.H. Lin, J. Cao, J.L. Qi, The regulation strategy for releasing residual stress in ceramic-metal brazed joints. J. Manuf. Processes. 85, 935–947 (2023)

X.W. Hu, N.F. Bao, Z.X. Min, Synergetic effect of strain rate and electroplated Cu film for shear strength of solder/Kovar joints. J. Mater. Sci: Mater. Electron. 30, 1434–1449 (2019)

J. Zhang, J.P. Xu, J. Huang, R.X. Liu, Y. Xiao, G.Q. Luo, Q. Shen, High shear strength Kovar/AlN joints brazed with AgCuTi/Cu/AgCuTi sandwich composite filler. Mater. Sci. Eng. A 862, 144435 (2023)

C.L. Xin, J.Z. Yan, N. Li, W.B. Liu, J.S. Du, Y.T. Cao, H.J. Shi, Microstructural evolution during the brazing of Al2O3 ceramic to Kovar alloy by sputtering Ti/Mo films on the ceramic surface. Ceram. Int. 42, 12586–12593 (2016)

X.J. Yao, Y.X. Zhao, Y.X. Huang, X.G. Song, D.F. Mo, J. Yang, A novel CoCrNi medium entropy alloy enhanced AgCuTi composite filler to braze Kovar alloy and sapphire. Mater. Charact. 197, 112668 (2023)

W.Z. Li, Z.J. Ding, H.T. Xue, W.B. Guo, C.X. Chen, Y. Jia, Z. Wan, Interfacial bonding mechanisms in ultrasonic-assisted soldered Si/Cu joint using Sn-3.5Ag-4Al solder. Mater. Charact. 199, 112833 (2023)

M.C. Halbig, M. Singh, H. Tsuda, Integration Technologies for Silicon Carbide-Based Ceramics for Micro-electro-mechanical systems-lean direct Injector fuel Injector Applications. Int. J. Appl. Ceram. Technol. 9, 677–687 (2012)

W.W. Zhu, J.C. Chen, C.H. Jiang, C.Y. Hao, J.S. Zhang, Effects of Ti thickness on microstructure and mechanical properties of alumina–kovar joints brazed with AgPd/Ti filler. Ceram. Int. 40, 5699–5705 (2014)

S. Zhao, H.Y. Chen, X. Nai, P.W.H. Deng, G.D. Wen, F.J. Liu, W.Y. Li, Effect of Ti content on microstructure and mechanical properties of SiCf/SiC composites/GH536 superalloy joints brazed with CoFeCrNiCuTi high entropy filler. J. Manuf. Processes. 85, 132–140 (2023)

Z.B. Chen, S.P. Hu, X.G. Song, Y. Lei, X.Y. Wang, W.M. Long, J.C. Feng, Brazing of SiC ceramics pretreated by chromium coating using inactive AgCu filler metal. Int. J. Appl. Ceram. Technol. 17, 2591–2597 (2020)

J. Yang, X.Y. Zhang, G.L. Ma, P.P. Lin, Y.Q. Xu, Z.G. Liu, T.S. Lin, P. He, K.J. Song, A study of the SiCf/SiC composite/Ni-based superalloy dissimilar joint brazed with a composite filler. J. Mater. Res. Tech. 11, 2114–2126 (2021)

H. Bian, Y.Y. Song, D. Liu, Y.Z. Lei, X.G. Song, J. Cao, Joining of SiO2 ceramic and TC4 alloy by nanoparticles modified brazing filler metal. Chin. J. Aeronaut. 33, 383–390 (2020)

M. Asghari, B. Beidokhti, S. Mollazadeh Beidokhti, Effect of the metallization method on properties of hybrid zirconia/Ti–6Al–4V joints. Mater. Chem. Phys. 296, 127212 (2023)

Z.Y. Wang, G. Wang, M.N. Li, J.H. Lin, Q. Ma, A.T. Zhang, Z.X. Zhong, J.L. Qi, J.C. Feng, Three-dimensional graphene-reinforced cu foam interlayer for brazing C/C composites and nb. Carbon. 118, 723–730 (2017)

R.J. Sun, Y. Zhu, W. Guo, P. Peng, L.H. Li, Y. Zhang, J. Fu, F. Li, L.X. Zhang, Microstructural evolution and thermal stress relaxation of Al2O3/1Cr18Ni9Ti brazed joints with nickel foam. Vacuum. 148, 18–26 (2018)

F.S. Jumbo, I.A. Ashcroft, A.D. Crocombe, M.M.A. Wahab, Thermal residual stress analysis of epoxy bi-material laminates and bonded joints. Int. J. Adhes. Adhes. 30, 523–538 (2010)

S. Mandal, A.K. Ray, A.K. Ray, Correlation between the mechanical properties and the microstructural behaviour of Al2O3–(Ag–Cu–Ti) brazed joints. Mater. Sci. Eng. A 383, 235–244 (2004)

Z.W. Yang, J.M. Lin, Y. Wang, D.P. Wang, Characterization of microstructure and mechanical properties of Al2O3/TiAl joints vacuum-brazed with Ag-Cu-Ti + W composite filler. Vacuum. 143, 294–302 (2017)

M.L. Santella, J.A. Horton, J.J. Pak, Microstructure of Alumina Brazed with a silver–copper-Titanium Alloy. J. Am. Ceram. Soc. 73, 1785–1787 (1990)

S.Y. Zhang, J.C. Lin, C. Wang, P. He, W. Wang, X.F. Zhang, T. Wu, H. Mei, Y. Liu, P.P. Lin, T.S. Lin, Improvement of microstructure and mechanical properties of Sapphire/Kovar alloy joints brazed with Ag-Cu-Ti composite filler by adding B powders. J. Manuf. Processes. 99, 243–253 (2023)

Z. Sun, L.X. Zhang, T.D. Hao, J.C. Feng, Brazing of SiO2f/SiO2 composite to Invar using a graphene-modified Cu-23Ti braze filler. Ceram. Int. 44, 15809–15816 (2018)

W.L. Wang, Y.L. Wang, J.H. Huang, Z. Ye, J. Yang, S.H. Chen, X.K. Zhao, Reaction-composite diffusion brazing of C-SiC composite and Ni-based superalloy using mixed (Cu-Ti) + C powder as an interlayer. J. Mater. Process. Technol. 300, 117419 (2022)

Y.T. Zhao, Y. Wang, Z.W. Yang, D.P. Wang, Relief of residual stress in Al2O3/Nb joints brazed with Ag-Cu-Ti/Cu/Ag-Cu-Ti composite interlayer. Arch. Civ. Mech. Eng. 19, 1–10 (2019)

M. Singh, J.M. Fernandez, R. Asthana, J. Ramirez-Rico, F.M. Valera-Feria, Effect of Mo and W interlayers on microstructure and mechanical properties of Si3N4-nickel-base superalloy joints. Int. J. Appl. Ceram. Technol. 20, 987–994 (2023)

W.W. Li, B. Chen, H.P. Xiong, W.J. Zou, H.S. Ren, Joining of Cf/SiC composite to GH783 superalloy with NiPdPtAu-Cr filler alloy and a Mo interlayer. J. Mater. Sci. Technol. 35, 2099–2106 (2019)

W. Guo, K. Li, H.Q. Zhang, Y. Zhu, X.Y. Shen, L. Zhang, H.W. Sun, S.J. Zhong, W.M. Long, Low residual stress C/C composite-titanium alloy joints brazed by foam interlayer. Ceram. Int. 48, 5260–5266 (2022)

J. Ba, B. Wang, X. Ji, H. Li, J.H. Lin, X.H. Zheng, J. Cao, J.C. Feng, Z.X. Zhong, J.L. Qi, β-LiAlSiO4 negative thermal expansion network interlayer for C/C–Nb brazing joint. Ceram. Int. 46, 14232–14234 (2020)

Q.Y. Zhu, Y.Y. Cai, Z. Liu, K.Q. Gong, Z.T. Wang, L.T. Li, Y. Zhang, Brazing Al2O3 to 4J42 using Ag–Cu–Ti/Cu/BNi-2 composite fillers with different thicknesses of Cu interlayer. Ceram. Int. 49, 9779–9788 (2023)

Y. Wang, Y.R. Wei, X.Y. Zheng, Z.W. Yang, Interfacial structure and mechanical properties of ZrO2 ceramic and GH4169 alloy joint brazed with Ag-TiH2 composite filler. Mater. Charact. 197, 112696 (2023)

V. Bhosle, E.G. Baburaj, M. Miranova, K. Salama, Dehydrogenation of nanocrystalline TiH2 and consequent consolidation to form dense Ti. Metall. Mater. Trans. A 34, 2793–2799 (2003)

A. Laik, P. Mishra, K. Bhanumurthy, G.B. Kale, B.P. Kashyap, Microstructural evolution during reactive brazing of alumina to Inconel 600 using Ag-based alloy. Acta Mater. 61, 126–138 (2013)

M. Min, Y.W. Mao, Q.R. Deng, G.M. Wang, S.G. Wang, Vacuum brazing of Mo to 316L stainless steel using BNi-2 paste and cu interlayer. Vacuum. 175, 109282 (2020)

Z.S. Cui, L. Huang, X.P. Meng, Q. Lei, Z. Xiao, Z. Li, Research Progress of Ultrahigh-Strength Copper-Titanium alloys. Metall. Eng. 7, 121–129 (2020)

Funding

This research was sponsored by the Natural Science Foundation of Hebei Province (Grant No: E2021202177).

Author information

Authors and Affiliations

Contributions

AHL contributed to formal analysis, visualization, writing—original draft; TW contributed to supervision; XGC contributed to investigation; WBG contributed to project administration, writing—review &editing, methodology; HTX contributed to funding acquisition; CXC contributed to supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, A., Wang, T., Chen, X. et al. Effect of Cu interlayer with different thickness on microstructure and properties of Al2O3/Kovar joints brazed with Cu–Ti/Cu/BNi-2 composite filler. J Mater Sci: Mater Electron 35, 660 (2024). https://doi.org/10.1007/s10854-024-12437-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12437-3