Abstract

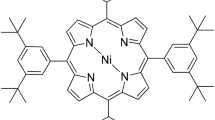

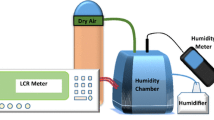

Thermally evaporated metal phthalocyanines (MPcs) were successfully fabricated for humidity-sensing applications. Comparative molecular analysis of three different MPcs sensing layers, namely MnPc, VOPc, and VTTBNc, using the powerful tool of grazing-incidence wide-angle and small-angle X-ray scattering (GIWAXS/GISAXS), were made to find the correlation between molecule orientation of the sensing layers and their humidity sensing performances. In this study, planar-configurated capacitive Al/MnPc/Al humidity sensor produced the highest sensitivity (17.74 nF/%RH) relative to Al/VTTBNc/Al (11.50 nF/%RH) and Al/VOPc/Al (11.20 nF/%RH) due to its crystallographic orientation being more vertical than the VTTBNc and VOPc counterparts, as confirmed by GIWAXS and GISAXS analysis. Similarly, the MnPc-based sensor produced the fastest response and recovery time of 3 s and 2 s, respectively. Meanwhile, VTTBNc yielded the smallest hysteresis gap of 0.29%. The quantitative and qualitative information, such as crystal coherence length, grain size, and lattice spacing obtained from the GIWAXS and GISAXS, have been studied to explain the humidity sensors’ sensitivity, hysteresis, and transient response. The crystallographic orientation of the active sensing layer significantly influences the humidity sensing performance.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

A. Kumar, H. Kim, G.P. Hancke, IEEE Sens. J. 13, 1329 (2012)

L. Lan, X. Le, H. Dong, J. Xie, Y. Ying, J. Ping, Biosens. Bioelectron. 165, 112360 (2020)

W. Jeong, J. Song, J. Bae, K.R. Nandanapalli, S. Lee, ACS Appl. Mater. Interfaces. 11, 44758 (2019)

L. Ma, R. Wu, A. Patil et al., Adv. Funct. Mater. 29, 1904549 (2019)

Z. Duan, Q. Zhao, S. Wang et al., Sens. Actuators B 317, 128204 (2020)

Z. Duan, Y. Jiang, M. Yan et al., ACS Appl. Mater. Interfaces. 11, 21840 (2019). https://doi.org/10.1021/acsami.9b05709

L. Ascherl, E.W. Evans, M. Hennemann et al., Nat. Commun. 9, 3802 (2018)

V. Montes-Garcia, P. Samori, Adv. Mater. (2023). https://doi.org/10.1002/adma.202208766

S. Park, Z. Zhang, H. Qi et al., ACS Mater. Lett. 4, 1146 (2022)

R.R. Cranston, B.H. Lessard, RSC Adv. 11, 21716 (2021)

N.A. Roslan, A.A. Bakar, T.M. Bawazeer et al., Sens. Actuators B 279, 148 (2019)

A. Jana, K. Kumari, A. Dey et al., Sens. Actuators A: Phys. 299, 111574 (2019). https://doi.org/10.1016/j.sna.2019.111574

N.A.M. Safian, A. Anuar, A.-Z. Omar et al., Sens. Actuators B 343, 130158 (2021)

Y. Zhu, Y. Zhang, J. Yu, C. Zhou et al., Sens. Actuators B 374, 132815 (2023)

R.R. Cranston, M.C. Vebber, J.F. Berbigier et al., ACS Appl. Mater. Interfaces. 13, 1008 (2021). https://doi.org/10.1021/acsami.0c17657

M. Berlinghof, C. Bar, D. Haas et al., J. Synchrotron Radiat. 25, 1664 (2018). https://doi.org/10.1107/S1600577518013218

Z. Peng, L. Ye, H Ade, Mater. Horiz. 9, 577 (2022). https://doi.org/10.1039/D0MH00837K

S. Dai, Y. Xiao, P. Xue et al., Chem. Mater. 30, 5390 (2018). https://doi.org/10.1021/acs.chemmater.8b02222

W. Chen, M.P. Nikiforov, S.B. Darling, Energy Environ. Sci. 5, 8045 (2012). https://doi.org/10.1039/C2EE22056C

T.V. Basova, V.G. Kiselev, I.S. Dubkov et al., J. Phys. Chem. C 117, 7097 (2013). https://doi.org/10.1021/jp4016257

J. Rivnay, S.C.B. Mannsfeld, C.E. Miller, A. Salleo, M.F. Toney, Chem. Rev. 112, 5488 (2012). https://doi.org/10.1021/cr3001109

A. Mahmood, J.L. Wang, Solar RRL. 4, 2000337 (2020)

L. Meng, K. Wang, Y. Han et al., Progress in Natural Science. Mater. Int. 27, 329 (2017). https://doi.org/10.1016/j.pnsc.2017.04.010

Z.J. Comeau, R.R. Cranston, H.R. Lamontagne, C.S. Harris, A.J. Shuhendler, BH Lessard, Commun. Chem. 5, 178 (2022). https://doi.org/10.1038/s42004-022-00797-y

T.J. Aldrich, S.M. Swick, F.S. Melkonyan, T.J. Marks, Chem. Mater. 29, 10294 (2017). https://doi.org/10.1021/acs.chemmater.7b04616

Z. Bi, H.B. Naveed, Y. Mao, H. Yan, W Ma, Macromolecules. 51, 6682 (2018)

Y. Yang, Z.-G. Zhang, H. Bin et al., J. Am. Chem. Soc. 138, 15011 (2016)

P. Scherrer, Nach. Ges. Wiss. Gottingen. 2, 8–100 (1918)

C.D. Bojorge, E.A. Heredia, HR Cánepa, Surf. Interfaces. 36, 102532 (2023). https://doi.org/10.1016/j.surfin.2022.102532

J. Perlich, J. Rubeck, S. Botta et al., Rev. Sci. Instrum. 81, 105105 (2010). https://doi.org/10.1063/1.3488459

B. Lee, C.-T. Lo, P. Thiyagarajan, D.R. Lee, Z. Niu, Q. Wang, J. Appl. Crystallogr. 41, 134 (2008). https://doi.org/10.1107/S0021889807051345

F.A. Natashah, A.A.M. Sabri, H. Alzahrani et al., Synth. Met. 293, 117299 (2023). https://doi.org/10.1016/j.synthmet.2023.117299

M.A. Najeeb, Z. Ahmad, R.A. Shakoor, Adv. Mater. Interfaces. 5, 1800969 (2018)

N. Turetta, M.-A. Stoeckel, R. Furlan de, Oliveira et al., J. Am. Chem. Soc. 144, 2546 (2022). https://doi.org/10.1021/jacs.1c10119

X. Zhang, D. He, Q. Yang, M.Z. Atashbar, Chem. Eng. J. 433, 133751 (2022). https://doi.org/10.1016/j.cej.2021.133751

R. Alrammouz, J. Podlecki, A. Vena et al., Sens. Actuators B 298, 126892 (2019). https://doi.org/10.1016/j.snb.2019.126892

M. Wang, Z. Zhang, H. Zhong et al., Angew. Chem. Int. Ed. 61, e202117210 (2022). https://doi.org/10.1002/anie.202117210

J.R. McGhee, J.S. Sagu, D.J. Southee, P.S. Evans, KU Wijayantha, ACS Appl. Electron. Mater. 2, 3593 (2020)

S. Ali, M.A. Jameel, C.J. Harrison, A. Gupta, M. Shafiei, S.J. Langford, Sens. Actuators B 351, 130972 (2022)

M.A.A. Rehmani, K. Lal, A. Shaukat, K.M. Arif, Sci. Rep. 12, 6928 (2022)

E. Ganbold, E.S. Kim, Y. Li et al., ACS Appl. Mater. Interfaces. 15, 4559 (2023)

Y. Mu, P. Jin, L. Zheng et al., Microchem. J. 191, 108934 (2023)

Acknowledgements

This research used resources from the Advanced Light Source, a DOE Office of Science User Facility under contract no. DE-AC02-05CH11231. An ALS Collaborative Postdoctoral Fellowship partly supported Aidan H. Coffey. The authors acknowledge the support provided by IUPAP-IUCr-ICTP LAAAMP.

Author information

Authors and Affiliations

Contributions

Fadlan Arif Natashah: writing—original draft. Syaza Nafisah Hisamuddin: formal analysis. Aidan H. Coffey: writing—review ānd editing. Chenhui Zhu: project administration. Tahani M. Bawazeer: visualization. Mohammad S. Alsoufi: Data Curation. Nur Adilah Roslan: resources. Azzuliani Supangat: supervision.

Corresponding author

Ethics declarations

Competing interests

The authors have no competing interests to declare relevant to this article’s content.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Natashah, F.A., Hisamuddin, S.N., Coffey, A.H. et al. Edge-on orientation of thermally evaporated metal phthalocyanines thin films for humidity sensing application. J Mater Sci: Mater Electron 35, 512 (2024). https://doi.org/10.1007/s10854-024-12280-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12280-6