Abstract

This work emphases on the effect of P/B ratio in Fe80B14−xPxSi5C1 (x = 0, 1, 2, & 3 at%) amorphous alloys on the thermal stability, soft magnetic characteristics, and magnetostriction properties. The addition of P in Fe80B14−xPxSi5C1 (x = 0, 1, 2, & 3 at%) amorphous alloys has a significant positive influence on the GFA. The addition of P element enhances the resistance to crystallization of amorphous alloys and broaden the optimal annealing temperatures range. The coercivity (Hc) of the Fe80B14−xPxSi5C1 (x = 0, 1, 2, & 3 at%) amorphous alloys is reduced from 15.6 to 9.03 A/m. The Fe80Si5B12C1P2 amorphous alloy exhibits excellent soft magnetic characteristics at the annealing temperature of 613 K for 3 min, with a Bs of 1.59 T and Hc of 3.8 A/m. Mössbauer spectroscopy have been used to investigate the origin of the variations in the Bs and Hc of the amorphous alloy after annealing. The saturation magnetostriction coefficient (λs) of Fe80B14−xPxSi5C1 (x = 0, 1, 2, & 3 at%) amorphous alloy decreases after P element doping and annealing treatment, which can be used to explain the change of Hc.

Similar content being viewed by others

References

Z. Huo, G. Zhang, J. Han, J. Wang, S. Ma, H. Wang, A review of the Preparation, Machining Performance, and application of Fe-Based amorphous alloys. Processes. 10, 1203 (2022). https://doi.org/10.3390/pr10061203

C. Suryanarayana, A. Inoue, Iron-based bulk metallic glasses. Int. Mater. Rev. 58, 131–166 (2013). https://doi.org/10.1179/1743280412Y.0000000007

H.R. Lashgari, D. Chu, S. Xie, H. Sun, M. Ferry, S. Li, Composition dependence of the microstructure and soft magnetic properties of Fe-based amorphous/nanocrystalline alloys: a review study. J. Non-Cryst Solids. 391, 61–82 (2014). https://doi.org/10.1016/j.jnoncrysol.2014.03.010

G. Herzer, Modern soft magnets: amorphous and nanocrystalline materials. Acta Mater. 61, 718–734 (2013). https://doi.org/10.1016/j.actamat.2012.10.040

X. Qi, J. You, J. Zhou, K. Qiu, X. Cui, J. Tian, B. Li, A review of Fe-Based amorphous and nanocrystalline alloys: preparations, applications, and effects of alloying elements. Phys. Status Solidi A 220, 2300079 (2023). https://doi.org/10.1002/pssa.202300079

J. Zhou, J. You, J. Qiu K, Advances in Fe-based amorphous/nanocrystalline alloys. J. Appl. Physs. 132, 040702 (2022). https://doi.org/10.1063/5.0092662

Q. Halim, Q. Mohamed, N.A.N. Rejab, M.R.T. Naim, W.N.W.A. Ma QJ, Metallic glass properties, processing method and development perspective: a review. Int. J. Adv. Manuf. Tech. 112, 1231–1258 (2021). https://doi.org/10.1007/s00170-020-06515-z

F.C. Li, T. Liu, J.Y. Zhang, S. Shuang, S. Wang, Q. Wang, A.D. Wang, J.G. Yang Y, Amorphous-nanocrystalline alloys: fabrication, properties, and applications. Mater. Today Adv. 4, 10027 (2019). https://doi.org/10.1016/j.mtadv.2019.100027

J.M. Silveyra, E. Ferrara, D.L. Huber, T.C. Monson, Soft magnetic materials for a sustainable and electrified world. Science. 362, eaao0195 (2018). https://doi.org/10.1126/science.aao0195

D. Chu, H. Lashgari, Y. Jiang, M. Ferry, K. Laws, S. Xie, H. Sun, S. Li, Recent progress in high Bs and low Hc Fe-based nanocrystalline alloys. Nanotechnol Rev. 3, 153–159 (2014). https://doi.org/10.1515/ntrev-2013-0030

J.F. Zhou, X. Wang, J.H. You, J. Pang, X.Y. Li, K.Q. Qiu, Excellent soft magnetic properties and enhanced glass forming ability of Fe–Si–B-C-Cu nanocrystalline alloys. J. Alloy Compd. 918, 165538 (2022). https://doi.org/10.1016/j.jallcom.2022.165538

X.S. Li, J. Zhou, L.Q. Shen, B.A. Sun, H.Y. Bai, W.H. Wang, Exceptionally High Saturation Magnetic Flux Density and Ultralow Coercivity via an Amorphous-Nanocrystalline Transitional Microstructure in an FeCo-Based Alloy. Adv Mater. (2022). https://doi.org/10.1002/adma.202205863

H. Li, A.D. Wang, T. Liu, P.B. Chen, A.N. He, Q. Li, J.H. Luan, C.T. Liu, Design of Fe-based nanocrystalline alloys with superior magnetization and manufacturability. Mater. Today. 42, 49–56 (2021). https://doi.org/10.1016/j.mattod.2020.09.030

Y. Zhang, P. Sharma, A. Makino, Effects of minor precipitation of large size crystals on magnetic properties of Fe-Co-Si-B-P-Cu alloy. J. Alloy Compd. 709, 663–667 (2017). https://doi.org/10.1016/j.jallcom.2017.03.193

L. Xue, W.M. Yang, H.S. Liu, H. Men, A.D. Wang, C.T. Chang, B.L. Shen, Effect of Co addition on the magnetic properties and microstructure of FeNbBCu nanocrystalline alloys. J. Magn. Magn. Mater. 419, 198–201 (2016). https://doi.org/10.1016/j.jmmm.2016.06.020

Y. Ogawa, M. Naoe, Y. Yoshizawa, R. Hasegawa, Magnetic properties of high Bs Fe-based amorphous material. J. Magn. Magn. Mater. 304, e675–e677 (2006). https://doi.org/10.1016/j.jmmm.2006.02.167

A. Inoue, T. Zhang, T. Masumoto, Zr-Al-Ni Amorphous-Alloys with High Glass-Transition temperature and significant supercooled Liquid Region. Mater. Trans. 31, 7–183 (1990). https://doi.org/10.2320/matertrans1989.31.177

A. Takeuchi, A. Inoue, Classification of Bulk Metallic glasses by Atomic size difference, heat of Mixing and Period of Constituent Elements and its application to characterization of the main alloying element. Mater. Trans. 46, 2817–2829 (2005). https://doi.org/10.2320/matertrans.46.2817

Q.A. He, Y.Q. Cheng, E. Ma, J.A. Xu, Locating bulk metallic glasses with high fracture toughness: Chemical effects and composition optimization. Acta Mater. 59, 202–215 (2011). https://doi.org/10.1016/j.actamat.2010.09.025

A.D. Wang, C.L. Zhao, A.N. He, H. Men, C.T. Chang, X.M. Wang, Composition design of high Bs Fe-based amorphous alloys with good amorphous-forming ability. J. Alloy Compd. 656, 729–734 (2016). https://doi.org/10.1016/j.jallcom.2015.09.216

X.F. Liang, A.N. He, A.D. Wang, J. Pang, C.J. Wang, C.T. Chang, K.Q. Qiu, X.M. Wang, C.T. Liu, Fe content dependence of magnetic properties and bending ductility of FeSiBPC amorphous alloy ribbons. J. Alloy Compd. 694, 1260–1264 (2017). https://doi.org/10.1016/j.jallcom.2016.10.107

H.E. Kissinger, Reaction kinetics in Differential Thermal Analysis. Anal. Chem. 29, 1702–1706 (1957). https://doi.org/10.1021/ac60131a045

N. Kawamiya, K. Adachi, Y. Nakamura, Magnetic Properties and Mössabauer investigations of Fe-Ga alloys. J. Phys. Soc. Jpn. 33, 1318–1327 (1972). https://doi.org/10.1143/JPSJ.33.1318

K. Narita, H. Fukunaga, J. Yamasaki, Effects of Metalloid Content on Curie temperature and magnetic moment of Amorphous Fe–Si–B Alloy. Jpn J. Appl. Phy. 16, 2063–2064 (1977). https://iopscience.iop.org/article/https://doi.org/10.1143/JJAP.16.2063

F. Mazaleyrat, R. Barrué, Chap. 3 - soft amorphous and nanocrystalline magnetic materials. Handb. Adv. Electron. Photonic Mater. Devices. 6, 59–102 (2001). https://doi.org/10.1016/B978-012513745-4/50052-4

H.X. Li, Z.B. Jiao, J.E. Gao, Z.P. Lu, Synthesis of bulk glassy Fe-C-Si-B-P-Ga alloys with high glass-forming ability and good soft-magnetic properties. Intermetallics. 18, 1821–1825 (2010). https://doi.org/10.1016/j.intermet.2010.01.021

T. Bitoh, A. Makino, A. Inoue, Quasi-dislocation dipole-type defects and low coercivity of Fe-based soft magnetic glassy alloys. J. Metastable Nanocryst. Mater. (2015). https://doi.org/10.4028/www.scientific.net/JMNM.24-25.427

A.D. Wang, C.L. Zhao, H. Men, A.N. He, C.T. Chang, X.M. Wang, R.W. Li, Fe-based amorphous alloys for wide ribbon production with high Bs and outstanding amorphous forming ability. J. Alloy Compd. 630, 209–213 (2015). https://doi.org/10.1016/j.jallcom.2015.01.056

T. Bitoh, A. Makino, A. Inoue, Origin of Low Coercivity of Fe-(Al, Ga)-(P, C, B, Si, Ge) Bulk Glassy alloys. Mater. Trans. 44, 2020–2024 (2003). https://doi.org/10.2320/matertrans.44.2020

C.C. Cao, L. Zhu, Y. Meng, X.B. Zhai, Y.G. Wang, Atomic level structural modulation during the structural relaxation and its effect on magnetic properties of Fe81Si4B10P4Cu1 nanocrystalline alloy. J. Magn. Magn. Mater. 456, 274–280 (2018). https://doi.org/10.1016/j.jmmm.2018.02.043

J. Xu, Y.Z. Yang, Q.S. Yan, C.F. Fan, F.T. Hou, Z.W. Xie, Effect of microalloying on crystallization behavior, magnetic properties and bending ductility of high Fe content FeSiBCuPC alloys. J. Alloy Compd. 777, 499–505 (2019). https://doi.org/10.1016/j.jallcom.2018.11.029

J. Dai, Y.G. Wang, L. Yang, G.T. Xia, Q.S. Zeng, H.B. Lou, Structural aspects of magnetic softening in Fe-based metallic glass during annealing. Scripta Mater. 127, 88–91 (2017). https://doi.org/10.1016/j.scriptamat.2016.09.006

J.S. Blázquez, J. Marcin, F. Andrejka, V. Franco, A. Conde, I. Skorvanek, Anisotropy field distribution in soft magnetic hitperm alloys submitted to different field annealing processes. J. Alloy Compd. 658, 367–371 (2016). https://doi.org/10.1016/j.jallcom.2015.10.210

H. Li, A.N. He, A.D. Wang, L. Xie, Q. Li, C.L. Zhao, G.Y. Zhang, P.B. Chen, Improvement of soft magnetic properties for distinctly high Fe content amorphous alloys via longitudinal magnetic field annealing. J. Magn. Magn. Mater. 471, 110–115 (2019). https://doi.org/10.1016/j.jmmm.2018.09.072

L. Wang, Y.Q. Zhang, Y. Jin, Y.H. Zhang, S.Y. Chao, Study of magnetostrictive coefficient of Fe-based amorphous alloys. J. Funct. Mater. 21, 21085–21088 (2014)

Z.Z. Yang, L. Zhu, L.X. Ye, X. Gao, S.S. Jiang, H. Yang, Y.G. Wang, Nanoscale structural heterogeneity perspective on the improved magnetic properties during relaxation in a Fe-based metallic glass. J. Non-Cryst Solids. 571, 121078 (2021). https://doi.org/10.1016/j.jnoncrysol.2021.121078

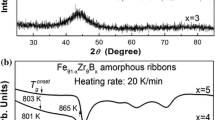

Q.H. Xu, S.S. Jiang, F.G. Chen, A. Jain, Y. Lin, Y.G. Wang, Effect of Zr/B ratio on β relaxation, structural heterogeneity, and magnetic properties of Fe-Zr-B amorphous alloys. J. Non-Cryst Solids. 594, 121822 (2022). https://doi.org/10.1016/j.jnoncrysol.2022.121822

J.V. Kasiuk, J.A. Fedotova, J. Przewoznik, J. Zukrowski, M. Sikora, C. Kapusta, A. Grce, A. Milosavljević, Growth-induced non-planar magnetic anisotropy in FeCoZr-CaF2 nanogranular films: structural and magnetic characterization. J. Appl. Phys. 116, 044301 (2014). https://doi.org/10.1063/1.4891016

Acknowledgements

None.

Funding

None.

Author information

Authors and Affiliations

Contributions

Q. Yan: Conceptualization, investigation, Writing—original draft, formal analysis. L.L. Lu: Investigation, Writing—review & editing. F.G. Chen: Investigation, visualization. Aditya Jain: Investigation, Writing—review & editing. Y.G. Wang: Supervision, validation, Writing—review & editing.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yan, Q., Lu, L.L., Chen, F.G. et al. Effect of P/B ratio on the thermal stability, soft magnetic properties and magnetostriction properties of Fe80B14−xPxSi5C1 amorphous alloys. J Mater Sci: Mater Electron 35, 418 (2024). https://doi.org/10.1007/s10854-024-12236-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12236-w