Abstract

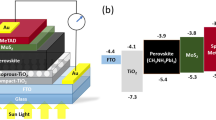

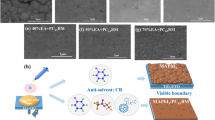

In recent years, organic-inorganic lead halide perovskites (OILHPs) have emerged as a promising photovoltaic material. These have very attractive optoelectronic properties such as high absorption coefficient, long carrier diffusion length and solution processability. However, the performance of OILHPs based solar cells is hampered by the imbalanced charge transfer in the perovskite photoactive layer. One of the ways to overcome these limitations is to have the photoactive layer in the form of bulk-heterojunction (BHJ) made of n-type perovskites and p-type low optical gap conjugated polymers. It has been observed that this leads to improvement in crystal size and decrease in non-radiative charge carrier recombination also. The two components in BHJ may not have suitable solubility in a single solvent. This can be a major hurdle in single step synthesis of BHJ. In this report we present a new strategy to overcome this problem. We report the use of Cyclohexane: Acetone: DMSO (CAD) microemulsion system as a solution composition for single step synthesis of BHJ of perovskite and indene C60-Bisadduct (ICBA). We have theoretically studied the progression of microemulsion states during the solidification process. For microemulsion to be stable, it needs a specific volume proportion of acetone, which depends on the composition of the microemulsion. Our study of solvent evaporation dynamics as a function of microemulsion composition and substrate temperature shows that the solidifying liquid film formed using the slot-die method, experiences sequence of stable/unstable states at various phases of solidification. The exact sequence along with temporal extent of each state depends on the starting composition. We observed that the structural and optoelectronic properties of BHJ are influenced by this behavior. We observed that when the initial microemulsion composition ensures its stability until final solidification, the BHJ formed has improved structural and optical properties. Thus, a suitable choice of initial solvent composition and substrate temperature can lead to improved perovskite: organic BHJ for use in optoelectronic devices. This study can lead to investigations of similar solution systems for synthesis of other two component BHJ active layers.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article [and its supplementary information files.]

References

U. Khan, Y. Zhinong, A.A. Khan, A. Zulfiqar, Q.U. Khan, Sol. Energy. 189, 421–425 (2019)

R. Datt, S. Bishnoi, D. Hughes, P. Mahajan, A. Singh, R. Gupta, S. Arya, V. Gupta, W.C. Tsoi, Sol. RRL. 6, 2200266 (2022)

R. Gupta, R. Datt, S. Barthwal, H. Sharma, A. Pandey, R. Deka, P. Sarkar, S. Husale, R. Srivastava, V. Gupta, S. Arya, S. Pathak, Mater. Adv. 3, 7865 (2022)

M.A. Afroz, A. Singh, R.K. Gupta, R. Garai, N.K. Tailor, S. Yukta, B. Choudhary, P. Sharma, B. Mahajan, S. Padha, S. Verma, V. Arya, S. Gupta, D. Akin, M.M. Prochowicz, S.P. Tavakoli, P.K. Singh, P. Iyer, H. Yadav, G. Hu, S. De, Satapathi, J. Mater. Chem. A 11, 13133–13173 (2023)

A. Sivaprakasam, N.K. Elangovan, J. Mater. Sci. 32, 17612–17619 (2021)

M. Makenali, I. Kazeminezhad, V. Ahmadi, F.A. Roghabadi, J. Mater. Sci. 32, 2312–2325 (2021)

C.H. Chiang, C.G. Wu, Nat. Photonics. 10, 196–200 (2016)

L. Shen, T. Zhu, X. Zhang, K. Gong, H. Wang, X. Gong, Nano Energy. 93, 106907 (2022)

L.L. Deng, S.Y. Xie, F. Gao, Adv. Electron. Mater. 4, 1700435 (2018)

C. Chang, C. Wang, R. Raja, L. Wang, C. Tsao, W. Su, J. Mater. Chem. A 6, 4179–4188 (2018)

D.K. Chaudhary, P. Kumar, L. Kumar, Chem. Phys. Lett. 685, 210–216 (2017)

M.J. Kim, M.H. Kim, J.S. Oh, N.H. Kwon, Y. Kang, J.Y. Yang, Sustainability. 11, 3867 (2019)

F. Wu, T. Chen, X. Yue, L. Zhu, Org. Electron. 58, 6–11 (2018)

D.P. Upasani, H.S. Tarkas, J.V. Sali, J. Nano Electron. Phys. 14(4), 04013 (2022)

S.R. Ha, W.H. Jeong, Y. Liu, J.T. Oh, S.Y. Bae, S. Lee, J.W. Kim, S. Bandyopadhyay, H.I. Jeong, J.Y. Kim, Y. Kim, M.H. Song, S.H. Park, S.D. Stranks, B.R. Lee, R.H. Friend, H. Choi, J. Mater. Chem. A 8, 1326–1334 (2019)

Y.S. Jung, K. Hwang, F.H. Scholes, S.E. Watkins, D.Y. Kim, D. Vak, Sci. Rep. 6, 20357 (2016)

J.E. Bishop, D.K. Mohamad, M.W. Stringer, A. Smith, D.G. Lidzey, Sci. Rep. 7, 7962 (2017)

H. Chen, Z. Wei, X. Zheng, S. Yang, Nano Energy. 15, 216 (2015)

J.H. Kim, S.T. Williams, N. Cho, C.C. Chueh, A.K.Y. Jen, Adv. Energy Mater. 5, 1401229 (2014)

J. Ghosh, P.K. Giri, Mater. Res. Bull. 139, 111255 (2021)

N. Le, N. Truong, T. Le, M.R. Pallavolu, H.J. Jeon, C. Park, Korean J. Chem. Eng. 38 1, 187–194 (2021)

J. Wu, Y. Wang, C. Su, H. Zhou, H. Xu, L. Jin, J. Sol–gel Sci. Technol. 100, 440–450 (2021)

R. Patidar, D. Burkitt, K. Hooper, D. Richards, T. Watson, Mater. Today Commun. S2352-4928, 30841–30844 (2019)

D. Lee, Y.S. Jung, Y.J. Heo, S. Lee, K. Hwang, Y. Jeon, J.E. Kim, J. Park, G.Y. Jung, D.Y. Kim, ACS Appl. Mater. Interfaces. 10 18, 16133–16139 (2018)

K. Hwang, Y.S. Jung, Y.J. Heo, F.H. Scholes, S.E. Watkins, J. Subbiah, D.J. Jones, D.Y. Kim, D. Vak, Adv. Mater. 27, 1241 (2015)

R.D. Morrison, Forensic applications of subsurface contaminant transport models, in Introduction to environmental forensics, 3rd edn., ed. by B.L. Murphy, R.D. Morrison (Sciencedirect, Amsterdam, 2015), p.555

S. Gamliel, I. Popov, B.E. Cohen, V. Uvarov, L. Etgar, Crystals. 6, 149 (2016)

T. Oku, Sol. Cells New Approaches Rev. 1, 77–92 (2015)

S. Pitchaiya, M. Natarajan, A. Santhanam, V. Asokan, V.M. Ramakrishnan, Y. Selvaraj, A. Yuvapragasam, B. Rangasamy, S. Sundaram, D. Velauthapillai, Mater. Res. Bull. 108, 61–72 (2018)

Y. Wang, T. Mahmoudi, W.Y. Rho, H.Y. Yang, S. Seo, K.S. Bhat, R. Ahmad, Y.B. Hahn, Nano Energy. 40, 408–417 (2017)

X. Hou, S. Huang, W.O. Yang, L. Pan, Z. Sun, X. Chen, ACS Appl. Mater. Interfaces 9, 35200–35208 (2017)

C. Quarti, G. Grancini, E. Mosconi, P. Bruno, J.M. Ball, M.M. Lee, H.J. Snaith, A. Petrozza, F.D. Angelis, J. Phys. Chem. Lett. 5, 279–284 (2014)

J. Chang, E. Feng, H. Li, Y. Ding, C. Long, Y. Gao, Y. Yang, C. Yi, Z. Zheng, J. Yang, Nano-Micro Lett. 15, 164 (2023)

Acknowledgements

Devashri P Upasani acknowledges the financial support by the Department of Science and Technology (DST) New Delhi under INSPIRE Fellowship Scheme.

Funding

This study was supported by the Department of Science and Technology (DST), New Delhi under the INSPIRE Fellowship program.

Author information

Authors and Affiliations

Contributions

JVSand DPU initiated the idea and designed the theoretical and experimental work. DPU performed the theoretical calculations and the experimental work. DPU analysed the results from characterization methods. SDB obtained the XRD patterns. MDS obtained the FTIR spectra and AFM images. SRJ, HST and YNC obtained the SEM images and EDAX data. DPU wrote the first draft of the manuscript, and all contributors provided feedback on the draft. With suggestions and input from all, JVS finalized the draft. Furthermore, each author declares that this or equivalent material has not been submitted to or published in any other publication and will not be submitted to or published in any other publication in the future. All authors read and approved the final paper, and they all agreed to submit it to the journal.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Upasani, D.P., Chaudhari, Y.N., Tarkas, H.S. et al. Perovskite-ICBA bulk-heterojunction thin films by slot die method: effect of microemulsion composition. J Mater Sci: Mater Electron 34, 2215 (2023). https://doi.org/10.1007/s10854-023-11617-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11617-x