Abstract

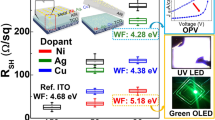

Transparent conductive oxide (TCO) films have significant applications in optoelectronic fields. In this study, we fabricated a large-area (> 3 × 7 cm2) indium–tin–oxide (ITO) film with rod coating strategy and low-temperature lightwave irradiation treatment. We investigated the crystallinity, morphology, and optoelectronic characteristics of ITO thin films using different indium chloride precursor concentrations. Results show that the optimal precursor concentration of 0.5 M allows the ITO films to have > 90% transmittance, < 16.4 Ω/sq sheet resistance, and a 2.39 × 10−2 Ω−1 figure of merit. These results are comparable or superior to those of small- or large-area ITO thin films prepared using the solution process. Overall, our findings pave the way for the fabrication of high-performance and large-area ITO transparent conductive films at low temperatures, facilitating potential applications in low-cost and large-scale TCO electronics.

Similar content being viewed by others

Data availability

All data used in this study are available from the author upon reasonable request.

References

R.A. Afre, N. Sharma, M. Sharon, Rev. Adv. Mater. Sci. 53, 79 (2018). https://doi.org/10.1515/rams-2018-0006

Z.W. Wang, C.N. Chen, K. Wu, H.N. Chong, H. Ye, Phys. Status Solidi Appl. Mater. Sci. (2019). https://doi.org/10.1002/pssa.201700794

H.S. Jung, G.S. Han, N.G. Park, M.J. Ko, Joule 3, 1850 (2019). https://doi.org/10.1016/j.joule.2019.07.023

D.J. Lipomi, B.C.K. Tee, M. Vosgueritchian, Z.N. Bao, Adv. Mater. 23, 1771 (2011). https://doi.org/10.1002/adma.201004426

V.D. Tran, S.V.N. Pammi, B.J. Park, Y. Han, C. Jeon, S.G. Yoon, Nano Energy 65, 104018 (2019). https://doi.org/10.1016/j.nanoen.2019.104018

S. Bok, H.J. Seok, Y.A. Kim et al., ACS Appl. Mater. Interfaces 13, 3463 (2021). https://doi.org/10.1021/acsami.0c20582

Y. Zhu, Z.Z. Sun, Z. Yan, Z. Jin, J.M. Tour, ACS Nano 5, 6472 (2011). https://doi.org/10.1021/nn201696g

H. Jiang, Y.N. Zhao, H. Ma et al., Opt. Express 31, 2208 (2023). https://doi.org/10.1364/oe.479098

M.M.D. Kumar, H. Kim, J. Kim, J. Nanosci. Nanotechnol. 16, 4993 (2016). https://doi.org/10.1166/jnn.2016.12186

A.N. Panckow, C. David, Vak. Forsch Prax. (Germany) 29, 21 (2017). https://doi.org/10.1002/vipr.201700652

S.M. Yang, B.S. Sun, Y. Liu et al., Ceram. Int. 46, 6342 (2020). https://doi.org/10.1016/j.ceramint.2019.11.110

L. Dong, G.S. Zhu, H.R. Xu et al., J. Mater. Sci. Mater. Electron. 30, 8047 (2019). https://doi.org/10.1007/s10854-019-01126-1

Y. Meng, X.B. Xu, H. Li et al., Carbon 70, 103 (2014). https://doi.org/10.1016/j.carbon.2013.12.078

J. Txintxurreta, E.G. Berasategui, R. Ortiz, O. Hernandez, L. Mendizabal, J. Barriga, Coatings (2021). https://doi.org/10.3390/coatings11010092

L.G.S. Albano, M.H. Boratto, O. Nunes-Neto, C.F.O. Graeff, Org. Electron. 50, 311 (2017). https://doi.org/10.1016/j.orgel.2017.08.011

Y.H. Cho, V. Raman, M. Beigtan, Y. Kim, H.K. Kim, ACS Appl. Electron. Mater. 3, 2953 (2021). https://doi.org/10.1021/acsaelm.1c00052

L. Zhou, M.J. Yu, L.Q. Yao, W.Y. Lai, Adv. Eng. Mater. (2022). https://doi.org/10.1002/adem.202101558

C. Ruan, Q.A. Sun, D.J. Xiao, H.Y. Li, G.D. Xia, S.M. Wang, Ceram. Int. 48, 12317 (2022). https://doi.org/10.1016/j.ceramint.2022.01.094

Y.F. Lan, W.C. Peng, Y.H. Lo, J.L. He, Mater. Res. Bull. 44, 1760 (2009). https://doi.org/10.1016/j.materresbull.2009.03.007

I. Madhi, W. Meddeb, B. Bouzid, M. Saadoun, B. Bessais, Appl. Surf. Sci. 355, 242 (2015). https://doi.org/10.1016/j.apsusc.2015.07.135

S. Benramache, O. Belahssen, A. Guettaf, A. Arif, J. Semicond. 35, 042001 (2014). https://doi.org/10.1088/1674-4926/35/4/042001

J.W. Kim, J. Choi, S.J. Hong, J.I. Han, Y.S. Kim, J. Korean Phys. Soc. 57, 1794 (2010). https://doi.org/10.3938/jkps.57.1794

K. Qin, F.S. Mei, T.H. Yuan et al., J. Mater. Sci. Mater. Electron. 29, 7931 (2018). https://doi.org/10.1007/s10854-018-8843-4

F.T. Nya, G.W. Ejuh, J.M.B. Ndjaka, Mater. Lett. 202, 89 (2017). https://doi.org/10.1016/j.matlet.2017.05.064

C.Z. Chen, S.W. Zhu, W.Q. Zhang, Y. Li, C.B. Cai, Res. Phys. 7, 2588 (2017). https://doi.org/10.1016/j.rinp.2017.07.039

S.H. Yu, L.H. Ding, C. Xue, L. Chen, W.F. Zhang, J. Non-cryst. Solids 358, 3137 (2012). https://doi.org/10.1016/j.jnoncrysol.2012.09.009

M. Ahmed, A. Bakry, A. Qasem, H. Dalir, Opt. Mater. 113, 110866 (2021). https://doi.org/10.1016/j.optmat.2021.110866

R. Ramanauskas, A. Iljinas, L. Marcinauskas et al., Coatings (2022). https://doi.org/10.3390/coatings12050670

P.P. Murmu, A. Shettigar, S.V. Chong et al., J. Materiomics 7, 612 (2021). https://doi.org/10.1016/j.jmat.2020.10.015

B.R. Lee, T.H. Lee, K.R. Son, T.G. Kim, J. Alloys Compd. 741, 21 (2018). https://doi.org/10.1016/j.jallcom.2018.01.122

M. Misra, D.-K. Hwang, Y.C. Kim, J.-M. Myoung, T.I. Lee, Ceram. Int. 44, 2927 (2018). https://doi.org/10.1016/j.ceramint.2017.11.041

L. Song, T. Schenk, E. Defay, S. Glinsek, Mater. Adv. 2, 700 (2021). https://doi.org/10.1039/d0ma00872a

S.-G. Ban, K.-T. Kim, B.D. Choi et al., ACS Appl. Mater Interfaces 9, 26191 (2017). https://doi.org/10.1021/acsami.7b07528

Y. Ren, X. Zhou, Q. Wang, G. Zhao, Ceram. Int 44, 3394 (2018). https://doi.org/10.1016/j.ceramint.2017.11.130

H.S. Akkera, P. Sivakumar, Y. Bitla et al., Phys. B Condens. Matter. (2022). https://doi.org/10.1016/j.physb.2022.413839

Funding

This work was supported by the Natural Science Foundation of Shandong Province (No. ZR2020MF104 and ZR2019MF031). Major innovation project for integrating science, education & industry of Qilu University of Technology (Shandong Academy of Sciences) (No. 2022JBZ01-07).

Author information

Authors and Affiliations

Contributions

All authors made contributions to the planning and design of the study. HL and CR: preparation of ITO film, interpretation of the data, and article writing. QS and MR: characterizations of film properties. SW and GX: Initiation of the work, funding acquisition, and article editing and revising.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, H., Ruan, C., Sun, Q. et al. Large-area rod-coated indium–tin–oxide transparent conductive films for low-cost electronics. J Mater Sci: Mater Electron 34, 2222 (2023). https://doi.org/10.1007/s10854-023-11565-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11565-6