Abstract

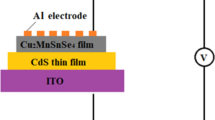

Cu2FeSnS4 (CFTS) is a promising p-type semiconducting material for thin film solar photovoltaics. Thin films of CFTS are deposited using vacuum spray pyrolysis technique onto soda lime glass substrate at different temperatures in the range of 325–400 °C. A low pressure of 10−3 m bar was maintained throughout the deposition of the films. Structural, morphological, optical and electrical properties of all the samples were studied. The energy band gap values are obtained from optical studies and it is in the range of 1.2–1.3 eV with the deposition temperature. All the samples showed good electrical properties including high values of conductivity in the range of 1–10 Scm−1 and mobility of the order of 102 cm2 V−1 S−1. The film deposited at 375 °C showed relatively better electrical properties than the other films. All the as-deposited samples are p-type in nature. p–n heterojunction with devices structure of < FTO/AZO/CFTS/Ag > are fabricated using aluminium doped zinc oxide as n-type layer. I–V measurements showed p–n junction diode characteristics for all fabricated devices with CFTS films deposited at different substrate temperatures. The lowest ideality factor of 3.09 was obtained for the device with CFTS films deposited at 375 °C.

Similar content being viewed by others

Data availability

No data are used for the reported research work.

References

C. Yan, C. Huang, J. Yang, F. Liu, J. Liu, Y. Lai, J. Li, Y. Yexiang, Synthesis and characterizations of quaternary Cu2FeSnS4 nanocrystals. Chem. Commun. 48, 2603–2605 (2012). https://doi.org/10.1039/c2cc16972j

S.A. Vanalakar, P.S. Patil, J.H. Kim, Recent advances in synthesis of Cu2FeSnS4 materials for solar cell applications: a review. Solar Energy Mater. Solar Cells 182, 204 (2018).

C. Dong, G.Y. Ashebir, J. Qi, J. Chen, Z. Wan, W. Chen, M. Wang, Solution-processed Cu2FeSnS4 thin films for photovoltaic application. Mater. Lett. 214, 287–289 (2018). https://doi.org/10.1016/j.matlet.2017.12.032

H. Guan, H. Shen, B. Jiao, X. Wang, Structural and optical properties of Cu2FeSnS4 thin film synthesized via a simple chemical method. Mater. Sci. Semicond. Process. 25, 159–162 (2014). https://doi.org/10.1016/j.mssp.2013.10.021

M. Adelifard, Preparation and characterization of Cu2FeSnS4 quaternary semiconductor thin films via the spray pyrolysis technique for photovoltaic applications. J. Anal. Appl. Pyrolysis 122, 209–215 (2016). https://doi.org/10.1016/j.jaap.2016.09.022

H. Oueslati, K. Nefzi, M. Ben Rabeh, M. Kanzari, Structural, morphological and electrical properties of the Al/p-Cu2FeSnS4 thin film Schottky diode grown by two method. Mater. Lett. 273, 127908 (2020). https://doi.org/10.1016/j.matlet.2020.127908

X. Meng, H. Deng, J. Tao, H. Cao, X. Li, L. Sun, P. Yang, J. Chu, Heating rate tuning in structure, morphology and electricity properties of Cu2FeSnS4 thin films prepared by sulfurization of metallic precursors. J. Alloys Compd. 680, 446–451 (2016). https://doi.org/10.1016/j.jallcom.2016.04.166

J. Zhou, S. Yu, X. Guo, L. Wu, H. Li, Preparation and characterization of Cu2FeSnS4 thin films for solar cells via a co-electrodeposition method. Curr. Appl. Phys. 19, 67–71 (2019). https://doi.org/10.1016/j.cap.2018.10.014

S. Wang, R.X. Ma, C.Y. Wang, S.N. Li, H. Wang, Effects of K ions doping on the structure, morphology and optical properties of Cu2FeSnS4 thin films prepared by blade-coating process. Optoelectron. Lett. 13, 291–294 (2017). https://doi.org/10.1007/s11801-017-7108-4

R. Amiruddin, M.C. Santhosh Kumar, Role of p-NiO electron blocking layers in fabrication of (P-N):ZnO/Al:ZnO UV photodiodes. Curr. Appl. Phys. 16, 1052–1061 (2016). https://doi.org/10.1016/j.cap.2016.06.003

P. Aabel, M.C. Santhosh Kumar, Deposition and characterization of earth abundant CuZnS ternary thin films by vacuum spray pyrolysis and fabrication of p-CZS/n-AZO heterojunction solar cells. Int. J. Energy Res. 44, 7778–7788 (2020). https://doi.org/10.1002/er.5515

C. Huang, Y. Chan, F. Liu, D. Tang, J. Yang, Y. Lai, J. Li, Y. Liu, Synthesis and characterization of multicomponent Cu2(fexZn1-x)SnS4 nanocrystals with tunable band gap and structure. J. Mater. Chem. A 1, 5402–5407 (2013). https://doi.org/10.1039/c3ta00191a

C. Rincón, M. Quintero, E. Moreno, C. Power, E. Quintero, J.A. Henao, M.A. MacÍas, G.E. Delgado, R. Tovar, M. Morocoima, X-ray diffraction, Raman spectrum and magnetic susceptibility of the magnetic semiconductor Cu2FeSnS4. Solid State Commun. 151, 947–951 (2011). https://doi.org/10.1016/j.ssc.2011.04.002

D.B. Khadka, J. Kim, Structural, optical and electrical properties of Cu2FeSnX4 (X = S, Se) thin films prepared by chemical spray pyrolysis. J. Alloys Compd. 638, 103–108 (2015). https://doi.org/10.1016/j.jallcom.2015.03.053

R. Swapna, M.C. Santhosh Kumar, Deposition of Na-N dual acceptor doped p-type ZnO thin films and fabrication of p-ZnO:(na, N)/n-ZnO:Eu homojunction. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 178, 1032–1039 (2013). https://doi.org/10.1016/j.mseb.2013.06.010

Acknowledgements

The author N. Aravind acknowledges the receipt of JRF funding provided by UGC, Govt. of India. The authors also acknowledge INUP programme for providing the characterisation facilities at IISc, Bangalore.

Funding

No funding received for this research work.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Conceptualization: MCSK, NA; Methodology: MCSK, NA; Formal analysis and investigation: NA; Writing - original draft preparation: NA; Supervision: MCSK. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that the authors have no competing interests as defined by Springer, or other interests that might be perceived to influence the results and/or discussion reported in this paper.

Ethical approval

This article does not contain any studies involving animal or human participants performed by any of the authors.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aravind, N., Santhosh Kumar, M.C. Effect of substrate temperature on the properties of Cu2FeSnS4 thin films by vacuum spray pyrolysis and fabrication of p–n heterojunction devices. J Mater Sci: Mater Electron 34, 1718 (2023). https://doi.org/10.1007/s10854-023-11133-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11133-y